Why are my small chisel secondary bevels coming out wonky?

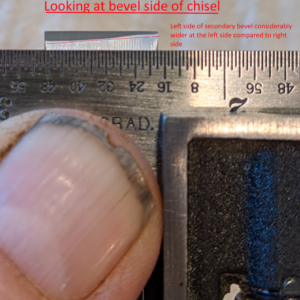

I’m working at sharpening a new set of chisels, putting secondary bevels on the cutting edges after flattening the backs. The secondary bevels on the two large chisels – 3/4″ and 1″ – came out looking “proper”, but the secondary bevels on the smaller chisels – 1/4″, 3/8″ and 1/2″ – all have the secondary bevel much wider on the left side of the chisel as shown in the attached picture. All of the chisel edges are reasonable square so that’s not the issue, I don’t think.

I’m using an eclipse-style honing guide so it seems like the obvious answer is there’s something wrong with my technique, but I’ll be darned if I can figure out what the problem is. These are “paring” chisels so the chisels go into the middle, slanted groove-like jaws and they look to be held square to the honing guide, with no possibility of movement.

I’ve tried putting more pressure on the side of the chisel with the narrow secondary bevel, but that doesn’t seem to do much or improve things. I feel like I’m putting even pressure on the chisel – side to side – and I’ve even resorted to trying to take arm flex out of the equation by only pulling straight back on the guide, rocking my body backwards at the ankles.

To get these secondary bevels squared up at this point should I be attempting to tilt the wheel of the guide such that the wheel is actually off the stone on the side of the chisel where the secondary bevel is “too wide?”

Replies

In my experience this happens when putting too much pressure on one side. It's really tough on very narrow chisels, 1/8 and 1/4. The narrow wheel on the jig makes it easy to tip.

On the plus side it's a great jig for putting a crown on plane blades, as you can apply pressure to both corners and get a nice little radius on the edge.

Is the primary bevel square? I mean square to the edges.

You mention flattening the backs, but nothing about the hitting the primary bevels. In your first picture, it looks like there's still machine marks on the chisel.

I'll join the bandwagon saying that your jig combined with narrow chisels and less than perfect technique have combined to create this situation.

Thanks for the responses.

@FiveBirdsCustom

Yes, the cutting edge right now is very square to the sides of the chisel.

I didn't really deal with refining the primary bevel itself as the secondary bevel is where the cutting action is actually taking place and as long as that's polished further polishing of the primary bevel should not affect things.

OR, are you suggesting that the primary bevel might not have been machined square to the top of the chisel, meaning the "high" side of the bevel (relative to the top side of the chisel, the side facing the stone) is what's getting removed first?

@esch 5995

If my technique is at fault - which probably is the case - it seems like the correction is to purposefully tilt the guide to favor the "narrow" side of the secondary bevel, widening it?

I started sharpening 30 years ago with that jig and it is very easy to rock it ever so slightly, especially with narrower chisels. I have long since moved onto a MK.II which has a much wider, hence more stable roller than eclipse jig and it's many clones. Obviously this is quite a different price range, even more so with all the accessories available, if that is not an option, I did eventually manage to get serviceable use out of mine. Pay close attention to how the chisel loads into the jig, I even used a fine file to clean up the shoulders where poor casting quality kept the chisels from registering accurately on mine. If you do this be careful and go lightly you could make the problem worse, just a few light passes on both sides is all I needed. After that focus on your technique, I feel using the eclipse style jigs is more akin to freehand sharpening than jigs like the Mk.II which because of it's stability is much more forgiving of flaws in technique. Use a stable stance, arms close to your sides and minimal movements and always linear. Go slowly at first until you get the feel for it and develop good habits. I'm sure you can find information on freehand sharpening here and YouTube. Your jig can maintain the angle for you but it won't be very forgiving of other poor practices in you technique.

I'll add another item on the list of things to check...

Is your stone flat?

A stone that's even slightly dished out will give inconsistent results.

Mike

“[Deleted]”

@MikeInOhio

I'm confident the stones are flat. I'm using Norton water stones and flattening them frequently with a Trend diamond plate, even going the extra step each time to pencil a grid of lines on the stones' faces and making sure the grid is completely removed.

I really thought my technique was OK but now I'm pretty sure it wasn't, so back to work.

I largely agree with the comments above, but I wouldn't worry about it too much. An offset secondary bevel is not a huge issue, especially for smaller-sized chisels. Once you re-grind the primary bevel when it needs it, you can then worry about making sure that the secondary bevel is parallel. Until then, have fun woodworking.

I use almost all the jigs from Kell to Veritas and everything in between. The Veritas MkII style with a wide wheel even has a disclamer saying "you may" get an uneven 2nd bevel but it's not an issue. When it happens though it's annoying to me visually. What I try to do on chisels especially is barely begin the 2nd bevel hone with light but even pressure, say a few strokes. You should be able to tell immediately if there is an unevenness begining to that 2nd bevel. I will typically compensate for any unevenness with hand pressure to make it even.

I use almost all the jigs from Kell to Veritas and everything in between (always using flat flat stones). The Veritas MkII style with a wide wheel even has a disclamer saying "you may" get an uneven 2nd bevel but it's not an issue. When it happens though it's annoying to me visually. What I try to do on chisels especially is barely begin the 2nd bevel hone with light but even pressure, say a few strokes. You should be able to tell immediately if there is an unevenness begining to that 2nd bevel. I will typically compensate for any unevenness with hand pressure to make it even.

OK, now I'm fairly well convinced that it's NOT my technique, it's the honing jig.

I inserted the 3/8" chisel into the honing guide, flattened all the stones, and was excruciatingly careful to keep the roller flat to the stones, but I was not able to hone out the skew. The only way I could widen the narrow side of the secondary bevel was to rock the entire jig over to the narrow side side of the bevel, lifting the opposite side of the roller completely off the stone. But if then continued honing after that, keeping the roller flat to the stone, only the wide side was getting polished.

I got out my dial caliper and measured the distance between the top of the jig, (the flat spot where plane blades rest), and the top of the chisel on the left and right sides. The difference between the two was about a 64th, with the side where the bevel was narrow being the shorter of the two.

Assuming this discrepancy translates down to the roller, and I have no way of measuring that, this would explain the skew in the secondary bevel.

I'm leaving things be for the moment and will probably pick up a different honing jig for the next sharpening.

I used the eclipse jigs for years, and they are very useful. They are also very poorly made, and require a bit of fitting. You get what you pay for.

I got a Lie Nielsen jig the day they came out, and couldn't be happier. It's essentially an eclipse jig, but made as a precision instrument. It's a lot more money, but for me, it's worth every penny.

This forum post is now archived. Commenting has been disabled