Hi,

I am new to this forum, but have a question about wood movement when milling away material for a custom extension dining table.

The table is 104″ long with a 13″ fold out leaf on each end, extended length 130″. The overall top thickness is 2.5″, with the leaves being 1.25″ minus a little bit for the hinge joint. The leaves will be contained underneath and attached to butler hinges that allow them to fold out, and a sliding mount will support them from underneath.

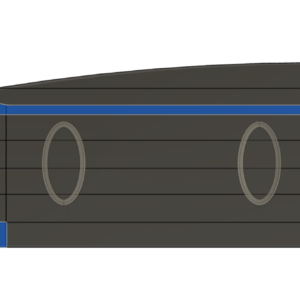

On the straight side of the table, the outer board will be 2.5″ thick, the middle 5 boards will be 1.25″, and the outer two on the curved edge will be 2.5″. The blue areas in the image represent 2.5″ material milled down to 1.25″ on a cnc. I am trying to juggle grain matching on the extending leaves and avoiding a lamination seam on the outside edges.

Anyone have any problems with wood movement as a result of milling down those areas, or other ways I could simplify this?

Also if anyone has any recs for sliding hardware to support fold out leaves, I know poettker but their hardware is 3″ thick, a bit too much for this project.

Thanks

B

Replies

Use KD lumber that has been dried to 7%, or so, then conditioned to relieve internal drying stresses. Check for stress before milling using the prong test recently described in FWW or see the Dry Kiln Operator's Manual, chapter 7 page 126. Wait 24 hours after cutting to the evaluate prong deflection (I don't think the DKOM says this).

Mill out most of the wood, wait a few days, then mill to final size. This allows movement (cup or warp) to occur prior to the milling the final size.

Avoid pieces with a lot of growth ring curvature (pieces that come from near the pith of the tree). These are more likely to cup with seasonal MC change. Quarter sawn material avoids the cup. Using rift sawn reduces the chance of it.

Use a wood with a small tangential to radial shrinkage ratio. T and R shrinkage can be obtained from the Wood Handbook, Chapter 4, Table 3. Cup generally increases with this ratio.

I'm sure others will have more ideas. Good luck with the project.