Fill the grain for a glass-smooth finish

Simple steps are key to success with pore fillers

Synopsis: You need only a few tools to use grain fillers, and grain-filling is pretty straightforward. Chris A. Minick explains the differences between oil-based and water-based options and tells you how to tint the filler, prepare the surface, apply the filler and remove the excess, and how to sand, clean, and seal it before you finish the piece. A side article by Andy Charron further details tinting and thinning oil-based fillers and offers some tips on using them.

Woods like mahogany, ash, walnut and oak, which have large pores, give a natural open-grained appearance to furniture. But to get a glass-smooth surface on these woods, you have to fill the pores with a grain filler before applying the finish. Tight-grained hardwoods, like maple and most softwoods, usually don’t require grain filling.

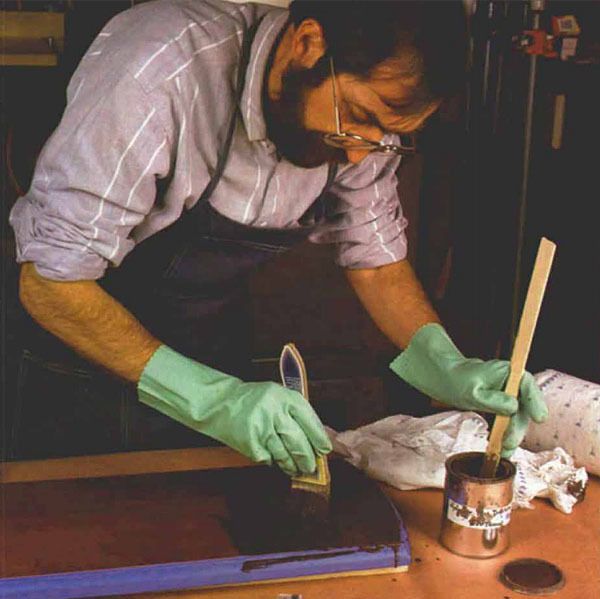

You need only a few tools to use grain fillers (see the photo at left), and grain-filling is pretty straightforward: Thin and tint the filler, prepare the surface, brush on the filler and pack the pores, remove the excess before it hardens, sand to the wood once the filler is dry, and clean off any residue. But though the process is straightforward, filling grain takes time, is messy and is generally not much fun. Even so, the results are well worth the effort, as the left side of the butternut board shows in the photo below right.

Oil-based and water-based options

Don’t confuse grain fillers with the wood putty used to fill nail holes. Grain filler, also called paste-wood filler or pore filler, is a thick clay-like mixture of solvent, resin binders and finely ground minerals, often called silex. Fillers come in oil-based formulations, like Behlen’s Pore-O-Pac (available from Woodcraft Supply, 210 Wood County Industrial Park, P.O. Box 1686, Parkersburg, W.V. 26102; 800-225-1153) or in water-based formulations, like Hydrocote’s Fast Dry (available from Highland Hardware, 1045 N. High land Ave. N.E., Atlanta, Ga. 30306; 800-241-6748). Both varieties can be purchased as a thick paste that must be thinned before use, or in a pre-thinned, ready-to-use consistency. Even though oil-based grain fillers have been around longer, I prefer water-based fillers because they work easier, dry faster and are easier to clean up. In addition, water-based fillers, once completely dry, are compatible with virtually all finishes.

Tinting the filler

Pore fillers come in a variety of wood tones, so you can match your project. They also come in off-white and in a neutral color, which can be custom-tinted in your shop. The choice of tint is a matter of taste. You may want a light, unobtrusive filler color on oak, or you may want to contrast the grain by using a dark filler.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Jorgensen 6 inch Bar Clamp Set, 4 Pack

Sawstop Miter Gauge

Log in or create an account to post a comment.

Sign up Log in