How to Make Cambered Cauls

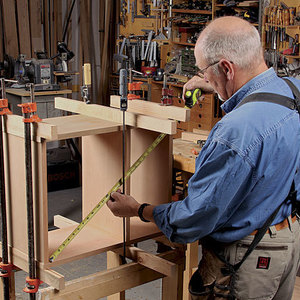

Get clamping pressure where you need it with easy shopmade caulsCambered or curved cauls are a great resource to have in your glue-up arsenal. Their slightly curved shape helps apply pressure to places where clamps alone can’t reach. One of their most common uses is in applying clamping pressure across the shelf dado in the side of a case piece, where it’s imperative to achieve pressure across the entire joint.

Learn how easy it is to make these cauls using your jointer, with this step-by-step tutorial.

Comments

A good glue-up is an example of cauls and effect.

Nice.

...actually, cauls and efclamps.

Running a cabinet shop here in England a few years ago we used lots of these to glue face frames on to plywood carcasses with biscuits. We made them all up about 900mm long 30mm thick and 40mm wide tapering to 32mm at each end, this gave the required pressure to clamp the biscuits joints up tight in the middle of the run. We used to draw the curve on the caul, plane off the bulk, and use an edge sander to clean up the curve.

I may be dense, but this clip would have been a lot better if it explained how to position the "curvy" side or the "straight" side when doing a glue-up. The author stated that both sides would be used. A simple explanation about how would have helped.

“[Deleted]”

The spinning jointer knives without the spring loaded guard being used on those wood cauls that could tip over gave me the willies.

There are other safer methods. A router used as an edge jointer or a taper jig on a table saw come to mind.

I used a hand plane to make mine. Gotta love hand tools.

Starting from the center of the caul, you’ve planed towards the end, flipped the board and repeated, taking off 1/32” from each half of the board. Except you left an unplaned step in the middle which you then smooth with sandpaper. It seems that this is not a tapered caul, but a stepped caul and I thought using a tapered caul was important when edge-gluing boards to make a panel. Increased clamp pressure from spring loading at the ends of the caul is necessary to close up the assembly and prevents the board edges from pulling apart on the ends.

Log in or create an account to post a comment.

Sign up Log in