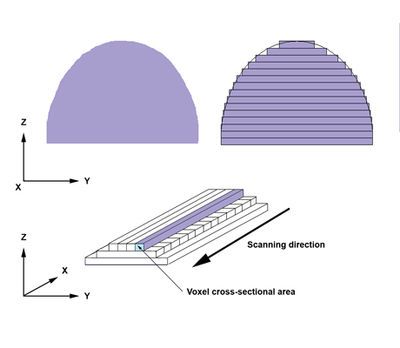

This small scale model of the design was created on a new tool for designers, called a 3-D printer. You send a CAD drawing to the printer, and a 3-D model comes out!

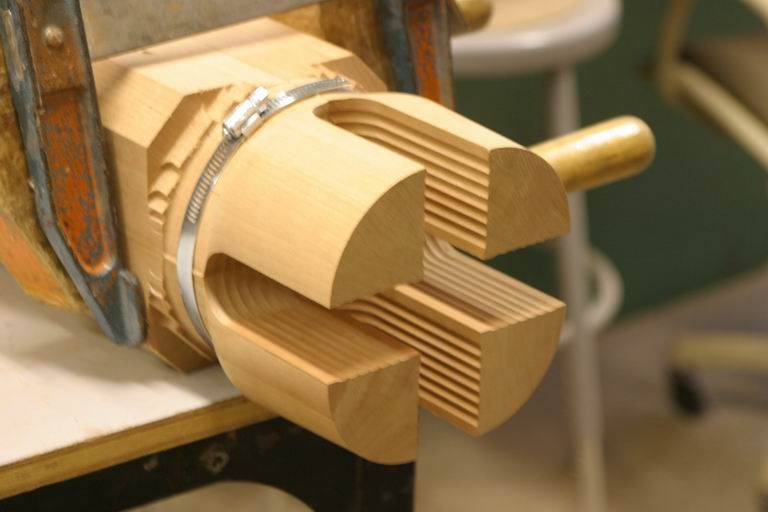

As a woodworker and problem-solver, I enjoyed a 2-day-long workshop by Bernhardt Design, a veteran company that designs and manufactures high-end, limited production pieces for the furniture industry. Called “Concept to Market in 36 Hours,” it was held mostly in a large woodshop at Appalachian State Univ., where craftsmen from the company built protoypes of a new design and tried to work out how it would be manufactured in production.

Design can’t really be rushed, so the organizers cheated a bit and developed the beginning drawings and models beforehand.

The designer, Kemal Gokturk, is from Savannah College of Art and Design, and he passed CAD models back and forth with the Bernhardt people in N.C. while working out the design.

| More from the 2009 Furniture Society Conference: • Furniture Society Conference Has an Industrial Focus • Furniture Society honors Vladimir Kagan |

Log in or create an account to post a comment.

Sign up Log in