Tokyo Dungeon Workshop

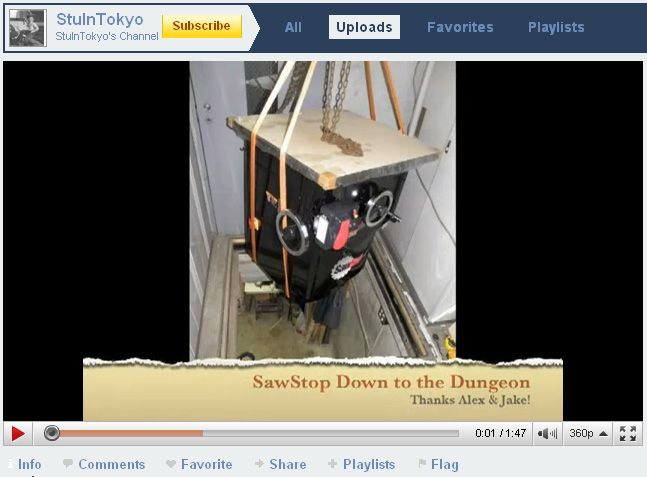

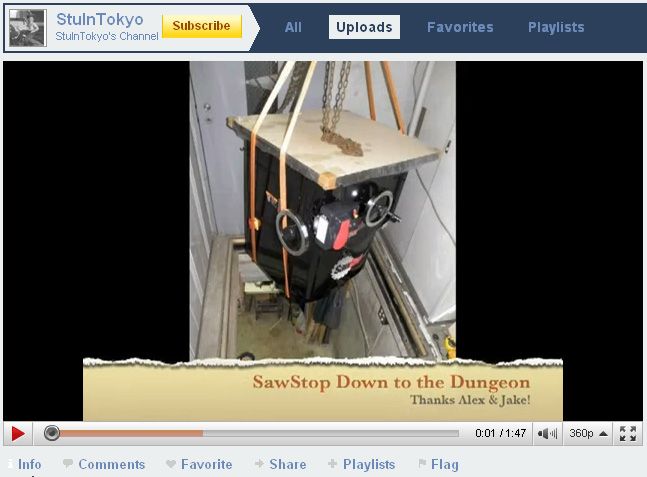

Stu Ablett of Family Woodworking getting a new tablesaw lowered into his "Dungeon Workshop."

With our new workshop gallery, we had to resurrect a post from our early GlueTube days… Stuart Ablett’s mind-boggling Dungeon Workshop in downtown Tokyo. (watch the video at the bottom of this post). Space is at such premium that he has to enter through a hatch in a parking area.

It’s only supposed to be a storage space so plumbing is now allowed. Instead, Ablett of Family Woodworking gets his water supply from his dehumidifier. If you make it through to the end of the video you’ll get to see Ablett’s dungeon “annex” through a hidden porthole.

For more, check out a video to see how Ablett got his new tablesaw into his tiny woodshop. Or, watch this short video clip that Ablett shot while contributing editor Garrett Hack was in Japan this winter.

Can your workshop top this? Post photos in our new shop gallery.

More on workshop design

Comments

Look's like a grow room

Uhhh, last time I looked at a map, Tokyo is NOT(!) in Connecticut.

Oh brother! I thought I had it bad with only 400 sq ft! Kudoos to you for being able to produce anything in so small a space, but trying to work in so cramped a space would make me crazy.

Wow, I'm really surprised that you guys did this, I had no idea, thanks!

To fill in a couple blanks, I'm in Tokyo, yes, downtown Tokyo and my space is around 14' x 23' or 322 sqft. I do have an AC that provides cooling in the summer and some heat in the winter, but being completely underground helps with a lot of the heating, and Tokyo seldom gets below freezing. Yes, no plumbing, so I have a catch tank to get the water produced by my AC (in the summer only) and my little dehumidifier I keep in the annex, not much water, but it is usually enough to wash my hands. I keep a case of bottled water on hand to drink, as well as a well stocked mini fridge.

I'll have to make up a new video tour as things have certainly changed since I put that last one up.

We certainly enjoyed Garret's visit, and I know that I learned a lot from him, even though the visit was short.

Thank you very much for posting this, I'm honored.

Stuart Ablett

Tokyo

Japan

Um...no water; one escape up a ladder; fire codes, anyone?!

Well you have to be a dedicated woodworker. I'm curious, how do you get the boat/china hutch/dining table out? It would be a chore to carry a jewel box up the ladder. Does the hatch that the machinery came through have a power hoist? My hat is off to you.

WOW kind of limiting as to what you can build down there isn't it?

How do you get anything large out? And I see all the sheet goods how do you get a 4x8 panel down there? If it was me I would keep the cars out and use the garage space above it.

Certainly would not work for a cabinet shop like mine but it must work out for you like to see examples of the stuff you manage to build down there.

You call that small? I should have a shop that size! While I do wonder how he manages to get material in and projects out of that tiny opening, his shop is about twice the size of my shop not including his "batcave".

My shop is in my basement and takes up about an 8 foot by 10 foot area. It works great for small projects, but when it comes to making furniture which is my main passion, I often have to assemble on my front porch or even the room the piece is intended for. I would not have the space for full assembly in my shop, and if I made space somehow, I'd never get the pieces out of the basement without damaging them.

I, like this guy no doubt, have found ways to compensate.

Anybody else notice that he's got the song "Turning Japanese" by the Vapors playing on his stereo throughout the tour? I like this guy's sense of humor!

Just a few answers and clarifications;

I have two escapes, one out the ladder to the hatch, and one to the next room through the hole in the wall. I also have two well placed fire extinguishers in the Dungeon. Perfect, no, but I'm a clean freak, and most above ground shops I see are often fairly untidy and fire traps too. I do the best I can with what I have. Also, I'm in "JAPAN" not the US, so the codes here and there are not the same. I know my 7 story building is well built and can withstand earthquakes, I know most buildings in the US could not, well ones outside of earthquake areas, no reason to build them for earthquakes if you don't have earthquakes.

On getting things out of the Dungeon, the hatch does open to a 4'x 4' square opening, and that is actually fairly big. I do have an electric hoist above the hatch, which I use for getting stuff up and down, it will do until 120Kgs, or about 260 lbs. Also remember, I'm in Japan, most people do not have the large amount of personal living space, so I would not be building huge entertainment centers, and even if I did, there would be the problem of getting a large cabinet into a client's home, the elevators are small, and the hallways are too, so I'd have to build it in small sections.

Plywood, well, that is not a problem, as the plywood comes in sheets that are 91cm x 182cm or about 3'x6', I can and do get those down into the Dungeon without a problem.

For larger stuff, here is a link to some wine shelves I built for our liquor shop.....

http://www.ablett.jp/workshop/images/wine_shelves/wine_shelves_in_place2.jpg

.... each shelf is about 3' wide, 18" deep and maybe 5'6" tall...? I got them out of the hatch... just.... but I did get it done. I usually don't build large stuff, and I do a lot of turning down there. I also have three phase power, which is great, as I got some good deals on used industrial equipment.

Cheers!

PS, thanks Brandster for noticing the music on the video, I did get in some trouble for that...... copyright infringement.....

OK, I finally got around to it......

Part 1

http://www.youtube.com/watch?v=bRbKhmyysIU

Part 2

http://www.youtube.com/watch?v=rjSGI7brFPs

Part 3

http://www.youtube.com/watch?v=fCfGf7BNfao

The first tour I did was just right around 10 minutes, for this one, well, I guess I had more to show and more to say :o

The three videos run around 27 minutes all together.

Cheers!

This guy must be a former Destroyer sailor where every inch of shipboard space is always utilized. It must be a real challenge to move sheet goods around down in his shop. That vertical ladder he has will make it real tough to navigate if he ever incures a leg injury. Very nice use of limited space & best of luck. Did they move Tokyo to Connecticut?

Stu - Kudos on the creative use of space. I also live in Japan, though way down here in Kochi. I have space you'd kill for, no doubt. Do have a couple of questions, though: I too thought about buying a SawStop until I saw the price the Japanese distributor was asking. !!! How did you manage to bring one from abroad? And, does running it on a Japanese current void warranty? Thanks!

YonedaD wrote:Stu - Kudos on the creative use of space. I also live in Japan, though way down here in Kochi. I have space you'd kill for, no doubt. Do have a couple of questions, though: I too thought about buying a SawStop until I saw the price the Japanese distributor was asking. !!! How did you manage to bring one from abroad? And, does running it on a Japanese current void warranty? Thanks!

Hi Yoneda, I had a friend buy the saw for me in Canada and ship it to me in Japan, I paid a brokerage fee and local shipping, all told came to about $5400 Canadian when it sat in my workshop, not bad as the Canadian dollar was at about 75 yen at the time :)

Taking the saw out of the area I bought it, that is Canada, voids the warranty right there, Can't be helped, but as you say the Japanese distributor wanted something close to $11,000 US for the saw setup the way I have it, I can buy a LOT of repair service and shipping for that kind of money. The saw has a motor and electrics that will run on the single phase 200V power I have here in Tokyo, they do sell a slightly different pulley to offset the slower speed because of the difference in power, but I've not bothered, and I've had no issues with the saw cutting, I've ripped 3" thick Hard Maple without any trouble.

Sorry for the late reply.

Stu.

PS if you are ever in Tokyo, come by for a visit, I'll give you the nickle tour :)

Thanks for the info, Stu. (And the invite! Same back at you if you're ever a mind to visit Kochi.) I decided to go the other route -- quality hand tools. Just got my Lie Nielsen No.9 miter plane and have an order in with Bad Axe. Figure for 100 万 I can raise the quality of all the tools in my workshop by a quantum tick or two. Not giving up my router table or bandsaw, though.

First off what a shop is very different for sure. I'd be in world of dodo with your shop. I'd end building something and not be able to fit through the hole to get it out of the shop.

But from what I have seen of your work, you seem to do quite fine with the situation.

How did a guy from Beautiful British Columbia, end up in Japan of all places. I'm from the lower mainland myself, you are like about the sixth or seventh guy from back home that I know of wwho is now living in Japan.

We will have to keep in touch......

Keep up the good work, by the way your bandsaw blog is great!!

Log in or create an account to post a comment.

Sign up Log in