Sizing small parts can be very dangerous with power tools. Ripping or cutting up a box side on the tablesaw could get your fingers uncomfortably close to the blade. It’s also hard to keep a firm hold on small workpieces.

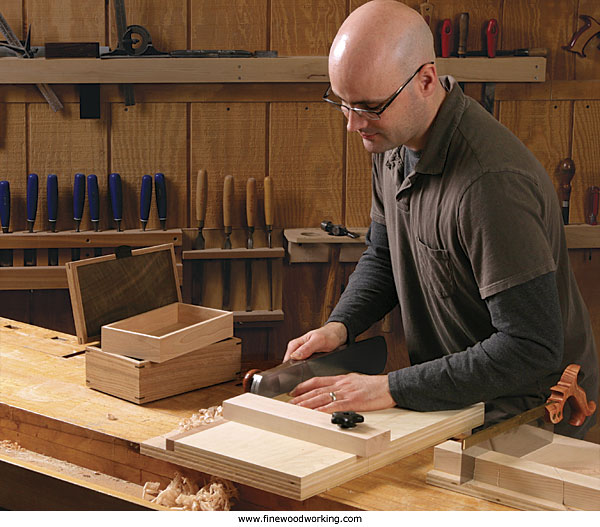

That’s why Matt Kenney likes to use a combination of jigs and hand tools. He’s found that the safest, fastest, and most precise way to make and fit small parts is using a backsaw, hand plane, planing stop, saw hook, and shooting board.

Matt wrote about this technique in an article in the latest issue of Fine Woodworking. He also demonstrated his methods in a box-making video workshop that we published in March. Watch an excerpt from the series in the video above where Matt shows how to make and fit small trays for a box.

For more, you can watch the complete box-making series. It’s free to everyone for this weekend only. After August 1, it becomes a member-only feature.

Now that you’ve seen and read about Matt’s technique, what do you think? How do you like to handle small parts in the shop?

Comments

As always, Matt does a great job in his videos!!!

Nice job, Matt.

Great video Matt,

Can you tell us about those grooving planes? Are they currently being made or are they vintage?

Thanks for the complements guys. It's nice to hear good feedback.

Jeff,

I made those planes and there will be an article about them sometime soon. I've written it and we have already shot the photos, but I can't say with certainty when it will be out.

Matt

Thanks for the article and videos, Matt. I made all three of the jigs and am finally using my iron miter plane as it was intended on the shooting board.

I'm looking forward to the article on the grooving planes.

One wrinkle I added to the taping of the sides of a tray was to clamp a 2' steel rule to the side of my bench and slide the tops (or bottoms) of the sides against the rule, outside face up, while taping, so the outer ends will come together properly when the four sides are folded together.

Excellent video, Matt. Perfect length and details.Thanks to Gina too.

Mike O'Brien, Valley Head,AL

When I make ukuleles and other projects with small parts that require close thickness tolerances and accurate bevels, I use jigs and double side tape the small part to the jig. The Ridged ocsillating belt sander with a mitre gauge works perfect and keeps my fingers away from the tool. I then use a shoothing board to obtain accuracies within .003". Small grooves can be made with a table mounted Dremel tool. I love hand tools, but its hard to beat the accuracy of well set up power tools.

Matt,

I am looking forward to constructing the shooting boards. A lingering question is what plane to you like for shooting board work? An iron miter plane comes to mind, but it is real pricey. Thanks for a great article. I've focused on small parts for awhile and your article will help me get the results I am looking for.

Dick

Matt,

After reading your article another time I noticed you mentioned using a low angle jack plane. I don't have one of those at present, but who knows what the future will bring. Thanks for your article and I have 2 of the 3 jigs made at this point.

Dick

I enjoyed the article and video and started to build the jigs. I am new to using hand tools but do enjoy the quiet in the workshop for a change. I am wondering what you used for the fences on your jigs? I have some hardwood some harder than others (I have some left over hickory from another project) The hickory it very hard and I just wondered what you would use if you had a choice?

Thanks for your feedback

Can't wait for the grooving plane article, I'd love to build some. The online extras and in conjunction with the article in the magazine have been a great asset to box making information I'm putting together.

Thanks Matt

keep up the good work!

Will the shooting board work with a jointer plane or fore bench plane?

The text for the shooting board calls for a 1/2" strip

of hardwood, but the drawing shows a 3/4" strip of hardwood.

I believe it should be 3/4", but what say you?

Art Silva

Log in or create an account to post a comment.

Sign up Log in