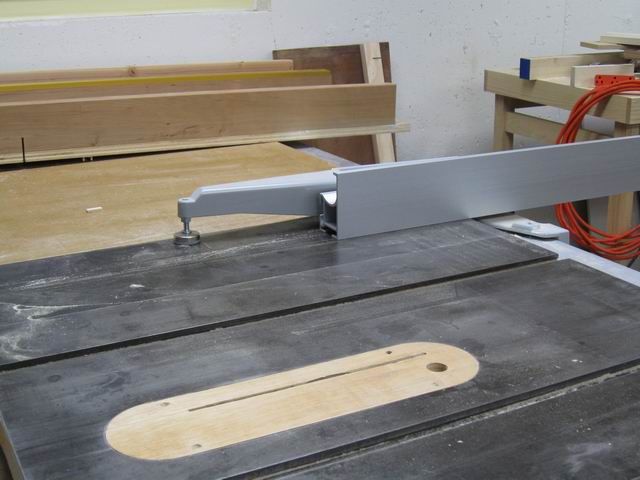

Rock solid and silky smooth. The Unifence is a t-square style fence that locks down tight and slides gracefully across the table.

Yes, it might be a bit blasphemous to equate glory with a table saw rip fence (or offensive in some other way, I’m sure), but the Unifence I recently installed on my Unisaw has been a tremendous, work-altering revelation to me. When I bought my Unisaw (see the story here), it had a disgusting, treacherous, and malign growth attached: a Jet-lock fence. The fence was inaccurate, hard to adjust, and had a slightly bent fence body. It was frustrating to use my saw. In fact, I never attempted any precise rips on it, because the fence just couldn’t perform. So I always longed to upgrade the fence. And I knew just the fence I wanted: a Delta Unifence. I’d used one quite a bit back in South Carolina, in the shop of my friend Joe Mazurek, and loved it. But a new Unifence was always a bit of a pipe dream (they retailed for about twice what I paid for the Unisaw). However, I recently caught a break on one and I am glad I did.

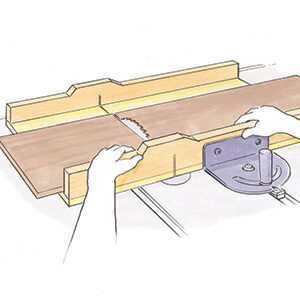

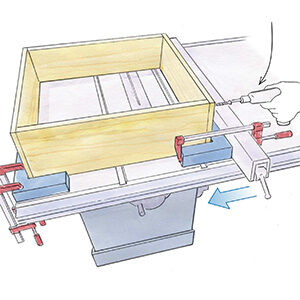

Here’s what I like. First, the Unifence is a fantasic t-square style fence. It slides smoothly along the saw table and extension fence, locks square to the blade every time, and doesn’t move a smidge once locked into place. Second, the fence can be slid to and fro on the clamping head, like rip fences on European saws. That means you can slide it back past the blade and use it as a stop for cross cutting. Third, the rule is accurate and I don’t have to measure from the blade to the fence repeatedly. I just line up the cursor to the distance I want, lock the fence in place, and go to work. Finally, and this is a huge plus for someone who likes to make boxes as much as I do, the fence body is actually two fences in one. In addition to the standard fence, there is a fence face for ripping thin stock. All you have to do is detach the fence body from the clamping head and rotate it 90 degrees. The standard face is then clamped to the head and a very short face now faces the blade. What’s the big benefit? Well, your hand is no longer cramped between the fence and push stick, and you can use a shorter push stick, which makes it easier to control the stock.

It’s like I have a brand new saw. Really. It’s no longer a machine for rough work, but a precision tool that I can trust every time I use it. And that makes me smile. (Now I just need to put in new bearings and hook up some dust collection.)

Here’s the bad news. Delta, I’ve been told, has stopped making the Unifence, which probably explains why I was able to buy one at 50% off retail. However, there still are some around. So, if you’re looking for a new fence, consider the Unifence. I’m glad I did.

(Safety note: You’ll notice that I don’t have a splitter or guard installed. That’s not because I’m a reckless fool. The throat plate that’s installed is for my cross-cut sled. Otherwise, I use a small splitter built into the throat plate. As for the guard, it’s sad to say that the saw didn’t come with one. However, I’m about to make one that hangs on a rigid, but adjustable, bar attached to the ceiling.)

Comments

Matt, can you post what your guard looks like when you get it installed? I'm curious as to what that is going to look like and if it's going to be shop-made or something like the HTC product.

thanks,

bb

Matt, can you post what your guard looks like when you get it installed? I'm curious as to what that is going to look like and if it's going to be shop-made or something like the HTC product.

thanks,

bb

Brian,

It will definitely be shop-made. I plan to make a the guard from Lexan and everything else from solid wood or plywood. I'm sure to post a blog about it when I'm done.

Brian,

I should have put this in my last comment. I'm using this design as a basis for mine: http://www.woodcentral.com/bparticles/blade_guard.pdf.

Good luck.

You speak my mind - I love my Unifence! I was not aware they are discountinuing it - that is a pity.

Of course, sometimes, the square profile of the T2 seems easier to build jigs for (those that straddle the fence), but I wouldn't trade still!

thanks,

Radha

I have a unifence as well - it is great! with a 50" rail I added I can take on almost any task.

Matt, I have to add a something else to your post: My Unisaw is a right tilt saw. There are times when I remove the 50 inch fence and put it on the right side of the T square unit and then move the whole unit to the left side of the blade. It's an awkward cut since I'm right handed...

On the con side: I wish I could buy a longer fence and I have yet to come up with a satisfactory auxilliary fence to clamp on for the times I rip a long 45 degree bevel.

Lastly, I bought mine in 1985 and the teflon rub blocks are no longer available.

Woodsmith,

My Unisaw is also right tilt. However, I almost never tilt my blade. I know that's odd, but it's just how I work. I steer clear of miters unless there for something small, like a box. In those cases, I use a chamfer bit at the router table or my shooting board and a low angle jack plane.

As for the teflon pads, I should probably track down some spares now, before they're no longer available. Thanks for the idea.

Maybe with this review Delta will reconsider? I too long for the $ to replace the fence that came with my Dad's Craftsman saw, circa 1962 or so. Now, I'll go looking but I bet the cost just went up. : )

I have this fence system also and I also have a right tilt saw. Changing the fence to the other side of the fence head is always a delay that I hate to take, when making mitered cuts. I've been looking for another unifence, just so I have an extra one already set up for making mitered cuts. If I upgrade to a left tilt cabinet saw, this fence is going to be changed over to it.

Nice post.

I bought this fence replacement for the Unifence extrusion and have used it for about 5 years. It was a very reasonable price and greatly improves on the ability to add jigs to the Unifence.

http://ttrackusa.com/unifence.htm

Does it clamp on the back? If not, why doesn't it flex? I was told that even a fly landing on a big I-beam caused flex.

I have had my Delta Contractor Saw and Unifence for about 10 years. After the initial set-up, I think I have adjusted it only once after a move. This is a very good fence, why would they discontinue it ?

Bill Shannon

Comment on the fence later, but first: Does anyone proof-read what this associate editor writes? "...trecherous, malign growth...."??? Hello?!! I guess he meant "treacherous, malignant"

As to the fence and the possibility it's being discontinued by Delta: One reason may be that customers aren't aware of the benefits of this adjustable fence. The biggest advantage, IMHO, and one that wasn't explained by this author, is being able to set the end of the fence in line with the center of the blade while ripping. This greatly reduces the liklihood of kickback. The ability to use it as a stop block is but a minor advantage compared to such a major safety technique.

Forrestgirl,

Thanks for catching the spelling mistake. However, "malign" is a perfectly suitable adjective. Also, thanks for giving us your opinion about another feature of the fence.

And for all those who have asked why it has been discontinued, I will attempt to get an official answer from Delta.

40heder,

Like all T-square fences, the Unifence doesn't clamp at the back. Does it flex under use? Perhaps, but if it does, it has no meaningful consequences on the fence's use. Also, the rips are still parallel, at least parallel enough for woodworking. If properly set up, I doubt you could measure any variance with a standard shop rule, which means the rips are more than accurate enough for building furniture.

Brian B.

I've been using the Unifence for years and love it. It's remained accurate and sturdy and still slides smoothly across the saw. I added a dust collecting guard that is attached to the ceiling of the shop. It has the ability to fold up out of the way when needed. Built out of 2" steel tubing and some parts from a different guard I had that was not as useful as it could have been both as a guard and in its dust collecting ability. I'd be happy to share a photo or two.

J

I've been using the Unifence for the 16 years I've owned my Unisaw. Great design with good ergonomics. The teflon buttons just glide over the miter slots & table extensions & allow you to raise the fence a bit over the table surface. Give the handle a twist and the whole assembly lifts right off to clear the table for a sled.

2X on the TtrackUSA aftermarket fence for the Unifence. I was never that impressed with the Unifence aluminum extrusion--nowhere to attach a featherboard, for example. The T-slots cast into all faces of the Ttrack fence are the fix :)

[img]http://ttrackusa.com/Assets/09_images/table_saw_images/uni_t_fence_01.jpg[/img]

I have a JET cabinet saw with the Jet "Xacta" fence. I have used the saw for over 15 years including a 600 mile relocation of my entire shop. I do check the alignment occasionally and the only time I ever had to make an ajustment was after the move. (That was quite easy to accomplish) I appreciate the simplicity of this fence design and the ease at which various jigs can be designed and used. I have watched friends that have the Unifence and gain more appreciation for the Jet Xacta fence each time. I wondered when Delta would discontinue offering this fence and I guess I can stop wondering now.

I too have a Delta X-5 Unisaw. It came with the Biesmeier fence which looks like a T-Style Fence. It adjust very easily and locks down tight. Once set, the measurement seems to be exact. Perhaps this is why the Unifence was discontuned.

Anyone have any comments as to why one is better than the other?

Thanks,

Jerry

I have a Delta Unisaw with the Unifence. Both Unifence and Biesmeyer fences were available when I bought the saw. I have often wondered if I should have chosen the Biesmeyer, as the difference I most often note while woodworking, is the ability of the Biesmeyer to move to either side of the blade. To move the Unifence to the other side of the blade requires a major reinstall of the fence, requiring several minutes of downtime. Also, it appears that the Biesmeyer might be able to more easily accommodate clamp-on jigs.

All the other previous positive comments relating to the Unifence I agree with. It has provided me with 10+ years of superb service.

I believe the Unifence would still be offered if it could service both sides of the blade without a reinstall.

I did a lot of shopping and comparing features of table saws when I set up my workshop. Most european saws are right tilt and have the Unifence type of rip fence with the high/low fence position feature so thin rips can be made at 45 deg. without cutting into the fence. On the other hand, it makes sense to use a Beisemeyer type of fence for left tilt saws because the blade tilts away from the fence. There has been a lot controversy over the safety of right vs. left tilt saws. It seems to me that the problem is to use the correct fence - Unifence type for right tilt, Beisemeyer type for left tilt. I hope Delta doesn't discontinue the Unifence - it is an excellent design and very well built.

I have used the Unifence for about 15 years and had a love/hate relationship with it. It is simple to remove and easily squared to the blade when reinstalled. And it is accurate. However, I often wished I could make sliding jigs but couldn't figure out how until I found this: http://www.ptreeusa.com/uni_t_fence.htm

Log in or create an account to post a comment.

Sign up Log in