AWFS Tool News: Austrian Engineering Comes to the U.S.

Are American woodworkers finally ready for European-style sliding tablesaws? Hammer certainly thinks so.

Ten years ago, when I first encountered Hammer machines, the value-oriented brand of the Felder Group, I found a slightly awkward attempt to de-engineer the vaunted Felder line of zero-compromise European machinery. Maybe that was because I am an American woodworker, but I was troubled by fences with too much flex in them, knobs that conflicted with each other, and small touches. In short there was just too much of a dropoff from the Felder perfection, where every single bit of the user experience is considered and made joyous. And a few poor reviews in magazines really hurt the Hammer brand.

Ten years ago, when I first encountered Hammer machines, the value-oriented brand of the Felder Group, I found a slightly awkward attempt to de-engineer the vaunted Felder line of zero-compromise European machinery. Maybe that was because I am an American woodworker, but I was troubled by fences with too much flex in them, knobs that conflicted with each other, and small touches. In short there was just too much of a dropoff from the Felder perfection, where every single bit of the user experience is considered and made joyous. And a few poor reviews in magazines really hurt the Hammer brand.

All that has changed, I believe. I was blown away by the two new Hammer machines I saw at AWFS in Vegas this year. The new Hammer A3 jointer-planer and K3 sliding tablesaw are SERIOUS woodworking machines, at very attractive prices considering what they offer and where they are built: 100% in Austria. And everything that bothered me before has been re-engineered, and then some. I just couldn’t find any problems with either of the new Hammer machines.

A3 Jointer-Planers

If you have ever considered a jointer-planer, which puts the two main milling machines into one small footprint and gets you a wide jointer to boot, you have to take a look at the new Hammer. Like the Felder, the two jointer tables come up at once, which is a real timesaver, and they only come up to 90 degrees not farther, so you can put this machine right against the wall. The other space-saver at the back is the fence system, which is unique and completely retooled. It has the same mounting location, down at the end of the table on a T-square bar, but it also has a locking plate right behind its center point, which greatly reduces flex. Also the fence is an aluminum extrusion, common on these machines, but much beefier than in the past, with its face machined dead-flat.

BUT WAIT, THERE’S MORE!

Both infeed and outfeed tables come up at once, and stop at 90-degrees, making this machine a real space-saver. click to enlarge

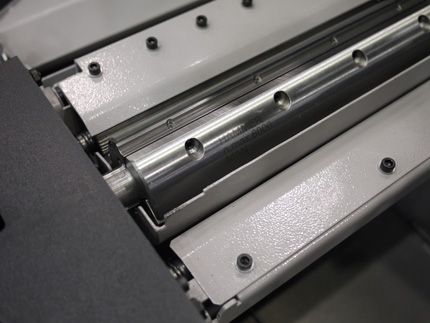

The innovations and improvements do not stop there. The tables ride up and down on dovetailed ways, a U.S. concept that makes them much more stable and allows them to be adjusted quickly and easily with a single lever as opposed to the old screw-handle. The flip-over dust hood works for both operations and is much roomier than the dust shrouds on similar machines which are very narrow in spots, choking airflow.

And two cutterheads are available. The standard one is Hammer’s version of a Tersa head, with two sided knives that are self-setting. But I was happy to see that the knives can be slid sideways to deal with a slight nick in them. The prices for the two standard machines are super-aggressive as they say in the industry, part of Felders attempt to re-establish the Hammer brand in North America. The 10-in.-wide model is $2,500 and the 12-in. version is $3,000. There is also a 16, too. All are available with Byrd Shelix segmented cutterheads, a fantastic upgrade that adds $700 to $1,000 to the price.

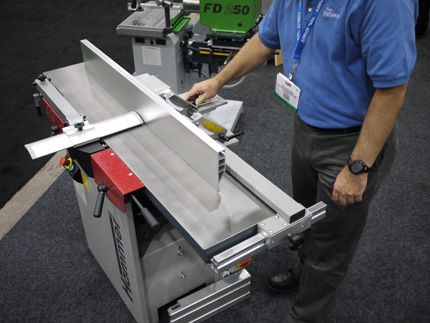

K3-W Sliding Tablesaw

If you’ve never tried a European sliding tablesaw, it takes a while to wrap your head around it. Ripping is basically the same, but there is a big table and large crosscut fence where U.S. style saws just have a miter slot and a blank section of table. Imagine a tablesaw that is actually ready to do big crosscuts. No need to build several shopmade sleds, and you get a built-in stop system on the fence. Also, no need to go to the bandsaw to get the first straight edge on a wany board; just clamp it to the sliding table and rip away. That’s just the start of what these machines can do. They excel on big pieces of plywood, and all kinds of jigs can be clamped to the sliding table.

One problem for American woodworkers with these machines in the past was the rip fences. Europeans do a lot of rip cuts with the sliding table, so the rip fences were relatively wimpy affairs. Hammer has fixed that, and every other concern I had in the past, with the new K3-W series. The rip fence is rock-solid, riding on a polished round bar like huge panels saws have, but it is adjustable to all kinds of handy positions, like all European fences are. The other fence, the one on the sliding table, has an adjustable stop to return solidly to 90 degrees (one of my other complaints). And the scales on both fences are both recessed for zero-wear and adjustable. The arbor also accepts dado sets, illegal in Europe but invaluable to U.S. woodworkers.

There are other great touches throughout, too many to list here. The lower dust shroud is one. It hugs the front of the blade tightly, right where the chips shoot downward, carrying them through a hose to a port in the cabinet. And the riving knife, a full-featured European one of course, is hardened and ground, and very stiff and smooth compared to others I’ve seen.

This is a serious sliding tablesaw, with a 12-in. blade and a single-phase, 4-hp motor, and low-vibration and low-slippage poly V-belts seen in high-end machinery. And it is very user-friendly. That’s why I was so surprised by the prices. The smallest version has a 31-in. table stroke and 31-in. rip capacity, for $3,000; and a 48×48 version is only $1,000 more, making these saws clear competitors for the new Unisaw and the SawStop cabinet saws, neither of which has a sliding table.

Comments

I've had my eye on the Hammer Table saw for quite awhile now, it will be my next major purchase. That will give me a second table saw, and save me a lot of time. They are a well built machine, first class all the way.

I have a Felder K700pro with a 270cm sliding table. But I am changing it out for a standard cabinet saw.

Why? well.... It is for a lot of reasons.

- The sliding table is made of aluminium and is therefor not magnetic. A lot of jigs an fasteners I have is based on magnets.

- The T-track slot in the aluminium is big, not your normal us size, and is also rounded in its shape. Not easy to make or buy 3 party accessories.

- Felder has no t-track in the cast iron part of the saw. That means that you only have one big t-track slot in the aluminium sliding table.(cross cut slade with one track?)

- Using the sliding table as a crosscut slade is heavy, no mather how well the x-track system is. It is a lot of mass to move.

- the slidingtable area which are on the left hand side of the saw blade is narrov. 10-12"

- The price is high very high. In fackt with mine sold I can buy a god cabinet saw, a separat planer, thikness planer, drill machine, mortiser and more.

- the sawblade have specialiced holes, 1 30mm and to small ones on the side. So you can't but standard sawblades at amanatools, rockler, etc. (if this in differnt in the US version I don't know)

But to cut sheet goods 4x8' it is perfekt, but using it for the small things it is just to heavy and pricy.

But this is only my oppinion.

Best regards Norway.

I have a competitor's sliding table saw. Nobody could believe I wanted an 8.5 foot slider in my two car .... studio, but having had it, I wouldn't live without it - with apologies to our friend from Norway, personally I can't imagine going back to a cabinet saw. (My vendor offers a short slider, and most of the people I know who have it, wish they had a long slider like mine). So my first criticism of the Hammer is the lack of long slider.

The Felder saws use the standard European 3 hole blades, which allows them to brake the blade with the motor without the momentum of the blade loosening the arbor nut. I wish my miter saw had that feature. My sliding table saw uses standard American blades, but cannot do dynamic motor braking, so takes 10 seconds to stop.

I do not miss the countless jigs required with a regular table saw, so the beefy hold-down track in the slider is fine, and the lack of 3/4 inch miter slot groove is a non-issue. MY most common jig on the slider is a scrap of plywood, clamped to the sliding table.

Boy I'd sure like to buy your K700 pro. What is the serial number and date of manufacture? And how did you get an "X" type table with 2700mm which has never been offered? Did you bother to check the Felder users site, FOG? There are more user made parts and information than any other off vendor web sight I know of. Sad you missed the KF 700 which adds the tilt shaper/router option with removable spindle with Byrd and Aigner options. Why have a sliding table and not have shaped/router capability.

red

I can tell you that I have their cousin, Felders 700 series and without a doubt they have the most impressive tools on the market in that price range. You can work with material with a digital readout that controls your measurements within 1/32 both on the panel saw and their jointer/planner with safety features that are a cut above those in the US as well as their dust collection, lending to a very clean environment. I would have no problem with a Hammer product as well, knowing how the company builds precision tools with thought.

I have the combination machine, which is basically the planer/jointer and tablesaw/shaper bolted together with some necessary mods. I'm quite happy with it. The Hammer quality is of course not Felder-level, but the price is about half and thus a more sensible financial proposition for the occasional woodworker like myself.

Obviously no single machine is perfect for everyone, but I can't imagine going back to a cabinet saw. Everything is simpler, more precise, and safer with a sliding table. Every time I see yet another article on the "perfect sled", I count my blessings and quickly turn the page...

I recently added the A3 31 12" Jointer Planer w/Shelix spiral head to my arsenal. So far I'm very pleased with it's performance. Plenty of power, incredibly quiet easy to switch between modes and very compact.

I purchased a sliding table saw back in 2007 and at the time looked at the Felder/ Hammer line and was pretty impressed. Although I ended up with a MiniMax SW315. The MiniMax to me seemed to be a little simpler in design and to be quite frank my buying experience with MiniMax was a lot less hassle and a lot less expensive. Originally I had a deposit down on a Hammer sliding table saw but when I went to pick it up it wasn't at all what I had thought it would be. I tried to negotiate an upgrade so I wouldn't lose my deposit of $1500.00. In the end it was actually less expensive for me to eat that deposit an purchase from MiniMax( Which by the way is the lesser line of SCMI). They got me out the door for about $8,600.00 for what Felder was trying to sell me for $12,000.00. And again to be quite frank the people at Felder came across very arrogant. Apparently the Europeans don't have the same attitude about customer service as we do here in America. That was very apparent on the internet a few years ago when the Laguna Co. got majorly slammed on the this sites blog (Knots). Some of these European Co's do a better job of shielding us Americas from their differing attitude about customer service (MiniMax being one of them). So just a word of caution, buyer beware. Be sure about what you want before you put down money,especially with Felder since they are the only one's that make you sign a contract that if you cancel they keep the deposit. My friend who just happens to make most of the store fixtures for the Costco Co. bought a Felder sliding table saw and had such poor service that he returned the machine and swore he'd never do business with them again, and he hasn't to this day. Point being: The European Co's that are selling us their wares need to learn that if they aren't satisfying their customers they won't get our business. Unfortunately I think the Europeans have been on a slow learning curve.

I have a Minimax CU 300 Smart w/8.5' Slider and a cabinet table saw. The set up allows me to do just about anything a circular table saw machine can do. My MM does not take well to a powerfeed so the traditional saw handles those tasks.

As for Felder, I went through their dance some time ago. They are underinformed and arrogant. They sell stripped down units and heap on everything you really need as an over-priced accessory. Minimax sells a pretty complete package at a fair price for excellent quality. The mortising attachment is remarkably accurate and fast. Minimax is solid quality and precision without the snobbery and over-pricing. I looked at Hammer, but went for a bigger machine. They would do nicely in a small shop.

I was living in Spain until last year and now I`m in Chile, when I was in Europe I had the chance to buy a Hammer Table Saw (integrated A3) and also a Hammer Band Saw, both are totally recomended. My workshop is now in Chile and I`m a very happy Hammer customer,

Regards from Santiago, Chile

This a 'wait-and-see' thingee.

For purchase, my primary issue is:Will you give me support? And, I insist that is in writing!

Re: support, I actually had a problem with my Hammer (an assembly defect with motor) that manifest about 8 months after purchase. I'll not bore all with details, but suffice to say service could not have been better, including multiple follow-up calls a week after problem resolution, both from the techs themselves and from service management, and then a followup call a month later just to be sure all was well.

Before I bought the Hammer I also considered all the competitive options (Minimax, Laguna, etc) but what I found is that unless wants to wait and travel to a show like AWFS, it's pretty much impossible to compare the alternatives first hand. For example, the nearest reference customer Minimax could offer was 500 miles from me. Felder has a showroom 80 miles away. That accident of geography influenced my decision.

Even if Hammer (and maybe others) become nearly cost-competitive with high-end cabinet saws, at least for now these are still niche machines built one-at-a-time to order, not commodity items like a Unisaw. The fact that the average potential customer can't easily even see one in real life is probably a significant impediment to market penetration.

I have the Hammer combination machine - table saw, shaper, jointer/planer combined in one. It was my present to myself on retirement 3 years ago. I've never used another type of machine, so can't compare, but I really can't see how I'd manage without a sliding table.

Log in or create an account to post a comment.

Sign up Log in