Chris Gochnour showed how to make a curved front desk in the latest issue of Fine Woodworking (#225). He inlaid the top with some narrow stringing. Here’s how he did it.

UPDATE

There have been a few questions about the cross-grain stringing at both ends of the table top. I spoke to Chris about this. Here’s what he had to say.

“It is indeed a crossgrain situation. That being said it has been done for centuries. Will it fail? That depends on several factors.

– How dry is the panel to begin with?

– How stable is the wood you are working with?

– Will the piece stay in an environment that has a fairly consistent climate?

I’m aware of a table that was made 25 years ago out of cherry with a crossgrain walnut band over about 7 feet. When I first saw it I was puzzled, but over the years I’ve noticed that there has been no issue.”

Phil Lowe also once told me (Matt Kenney) that with this type of stringing “failure or success mainly depends on how well the wood is seasoned and the enviroment it will live in. If the space is climate controlled, no problem.”

|

Cut stringing at the bandsaw Gochnour ripped 1/8 in. thick strip from a larger blank of wood and then ripped 3/32 in. wide strips from them. |

|

| click to enlarge | ||

|

Rout the grooves Use a 1/8 in. diameter straight bit, guided by a 1/4 in. O.D. bushing. The same template can be used for the curved and straight lines, because one edge is curved and the other straight. To accomodate for the bushing’s offset, align the template 1/8 in. to the inside of a centerline drawn to locate the grooves. Because he wasn’t able to see the bit as it cut, Gochnour did not attempt to cut the grooves all the way to the ends. Rather, he stopped his cut about 1/4 in. short. |

|

| click to enlarge | ||

|

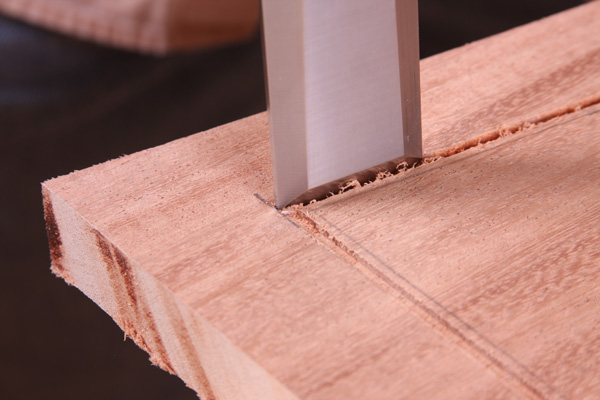

Complete grooves with a chisel. Use on that is wide enough to finish the side of the groove in a single cut. Then clean out any waste with a 1/8 in. wide chisel. |

|

| click to enlarge | ||

|

Miter the stringing in place. Align a straightedge (Gochnour’s is made from MDF) on the diagonal at the corner and cut the stringing with a chisel. This eliminates any need to determine what the miter’s angle. |

|

| click to enlarge | ||

|

Plane the stringing flush. After gluing the stringing in place and the glue has dried, bring the stringing level to the top with a smoothing plane. |

|

| click to enlarge |

Comments

has anyone noticed . . . this is not a video!!!

Video would be nice. More details, better explanations.

Beautiful Desk! The kind of work I have come to expect from Chris Gochnours. However, I have not been able to find a cutting list; and also what kind of wood is he using?

Was there supposed to be a video?

Cool, but I've always wondered: won't the stringing running cross grain present some problems in terms of wood movement? I imagine the contracting and expanding top itself overpowering the stringing and maybe popping it out, or at least knocking the joints out of whack. And yet, it's been done for probably thousands of years, so what am I missing?

The primary wood of the desk is Sapele or Africa Mahogany.

Yup I'm with ya, a video woul be nice.

Folks,

I'm sorry there is no video and I apologize if we somehow gave the impression there would be one. If you let me know where you saw mention of a video, I'll look into it. There was never supposed to be one. These photos are taken from the photo shoot I did with Chris for the article. We ran 10 pages on the table in the magazine and it still wasn't enough space!

As for the wood, the primary wood is African mahogany and the stringing is some type of Rosewood or Cocobolo. Both would give the same look.

The video is "mentioned" in the email cover page the I received.

Correction, the video is "mentioned" in the Current Issue Table of Contents. Sorry for the error.

I have the same question re the stringing across the grain and wood movement of the table top. Surely the stringing could break over time, couldn't it? I read in an earlier issue of FWW something about using end grain stringing for the cross grain portions. I would like the author's opinion on this.

I checked the table of contents from FWW #225 (the issue that has this article in it). The blurb that mentions this online extra (p.6) does not mention a video, nor does the online extra box in the article itself (p.52). In both cases, the text reads "Learn how ..."

I don't recall the eletter, but I'll look into it.

A cutting list list would be nice, so i as a beginer could follow but make my own adjustments as i progress.

I'm currently trying to make Kevin Kauffunger's hall table with 1/16th stringing and the in FWW 212. On page 34 he suggests using cross-grain stringing.

Mike Collins

implied link to video to this page, from "view current issue" page.

regards

Patrick

The explanation is not terribly convincing, but experience and history trumps all! If it works, it works. I'll have to try this for myself, and keep the piece for at least a year! BTW - Chris's table design is graceful.

I'm preparing to build this very desk this autumn from the Taunton plans they sell. I already do stringing and banding (thanks to inspiration from Steve Latta) so that's not an issue for me. I'll be making it out of maple though, because that's what I have and maple is great wood.

I won't be posting any videos of it though! :)

Log in or create an account to post a comment.

Sign up Log in