Hawaiian Steel Guitar Project-Part 3

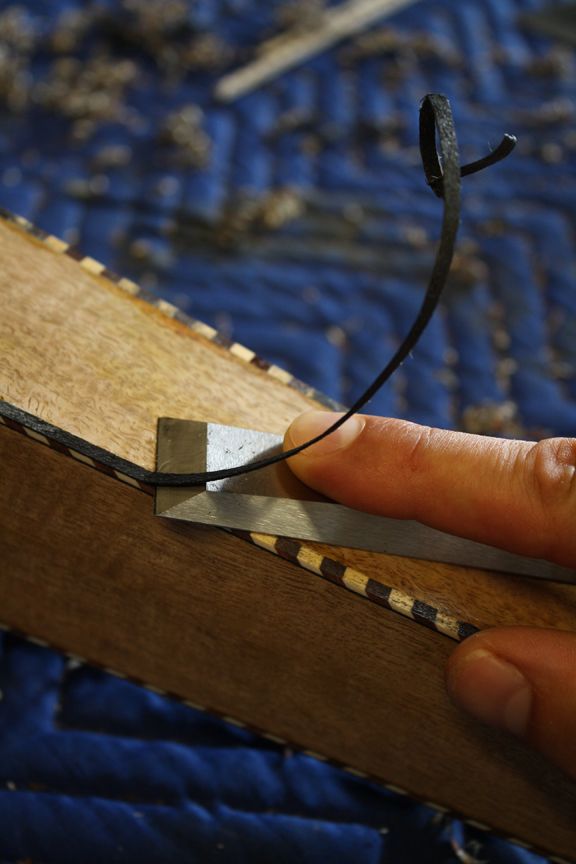

After the top and back are fit to the sides, they are trimmed with a chisel to overhang the sides by about 1/8 of an inch.

In Part 2 the guitar back was fit to the sides. In Part 3, the sound box is now together, and from a few taps on the top and speaking into the soundhole – it seems like this guitar is going to be loud. To help make the glue-up easier, I made a bunch of “spool” clamps. Simply cut sections of 3/16″ in. threaded rod about 6 inches long and add a 1/2 thick slice off a 1 1/2 in diameter dowel to each end. A washer and wing nut at each end allow clamping pressure from both sides.

The rope binding was a little tricky (I had to go back and re-do one section at the waist) but I think the extra time was worth it to add a little traditional detail. The rope binding is bent on a hot pipe and then glued to a small rabbet around the top and back edges. I used a rabbeting bit with a bearing to rout the top and back. I added blue tape to the bearing until I got the correct rabbet depth – leaving just the outer black strip proud of the sides, to be later removed exposing the “rope”.

Log in or create an account to post a comment.

Sign up Log in