Jet, like Powermatic, is undergoing a design revolution for all its tools. The company is reenergizing itself by refocusing on clever, innovative designs for its tools that are attractive and useful. This is a scale model of a benchtop lathe they're working on.

When we met with the folks at Powermatic last year at AWFS, they didn’t have many new tools to show us. Instead, they spoke with us about their plans to refocus and rebuild their tool line from the ground up, looking to offer no-compromise machinery designs for woodworkers.

According to Barry Schwaiger, director of product development, that means tough choices. He says, “It’s easy to breathe your own exhaust,” a clever way of saying keeping the status quo. But Powermatic is turning its franchise on its head, says Schwaiger, and plans on “wiping out existing categories and starting from scratch.” With a new priority on product development and innovation, it looks like Powermatic’s strategy is paying off. Earlier this year they rolled out a beast of a lathe, the 4224B. At IWF they’ve introduced a new drill press and new bandsaw, both of which offer innovative features that any woodworker will appreciate.

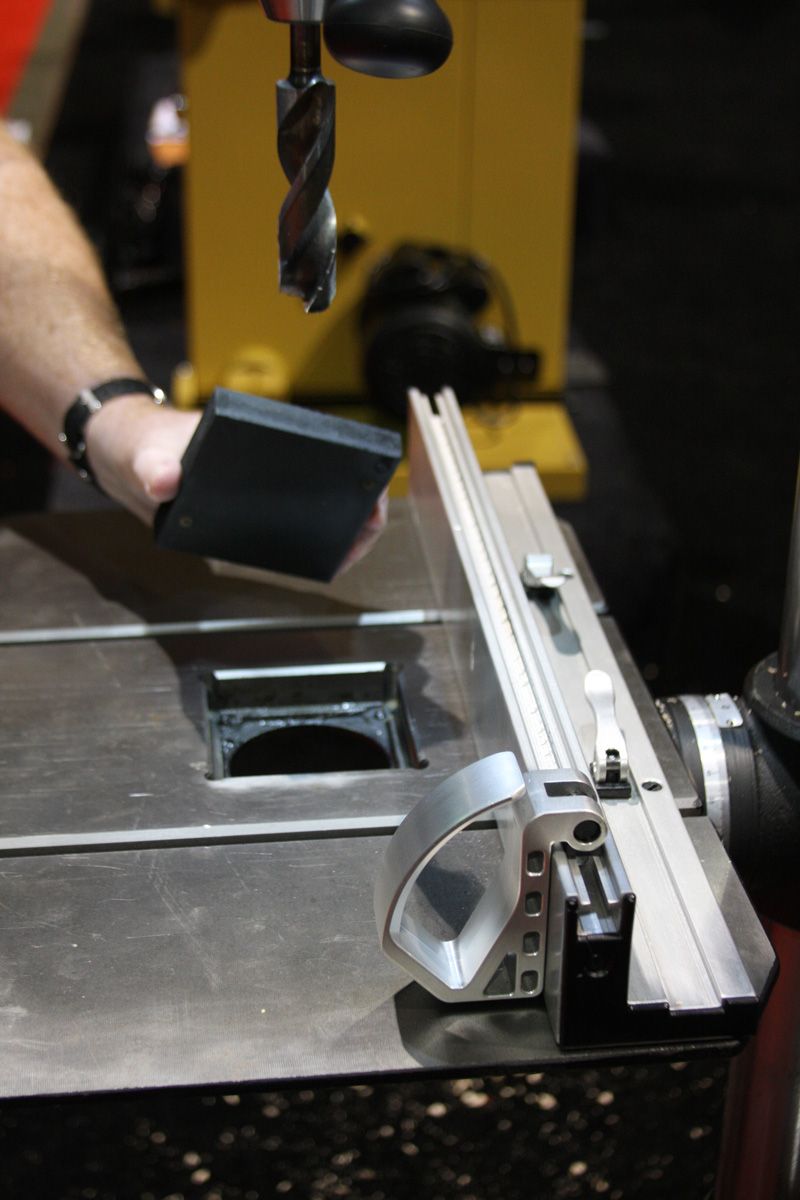

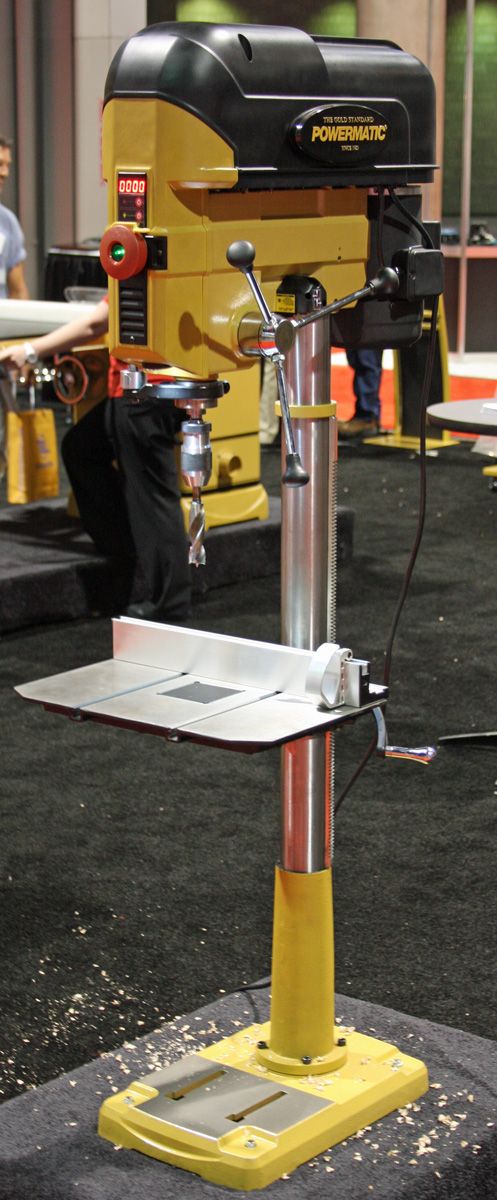

Better drill press for woodworking

The 18 in. drill press, model No. PM2800B, will replace Powermatic’s PM2800, and boasts plenty of improvements from the ground up. The base is bigger, giving a stronger, more stable footprint. The table also is bigger, with features that practically eliminate the need to make an accessory table to give you a larger worksurface. The table on the new drill press is square, with a handy clamping ring around the lower edge. It also has a convenient pop-out insert that can be replaced with a shopmade version when it’s worn out. The included fence features an easy-to-use cam-action sliding stop that locks in place with one hand.

Other features include a keyless chuck and LED lights in front and back of the chuck, locations that eliminate that annoying shadowline created by the bit. There’s 6 in. of quill travel with one rotation of the handle, and the spring-tensioned handle won’t fly out of your hands if you release it, eliminating knuckle raps.

The machine is super quiet at all speeds, and speed changes are accomplished with a handwheel on the side of the motor. Simply rotate the wheel while the machine is running, and dial in the speed by following the digital readout on front.

According to Schwaiger, the PM2800B will be available at the end of the year, with a street price of around $1,300.

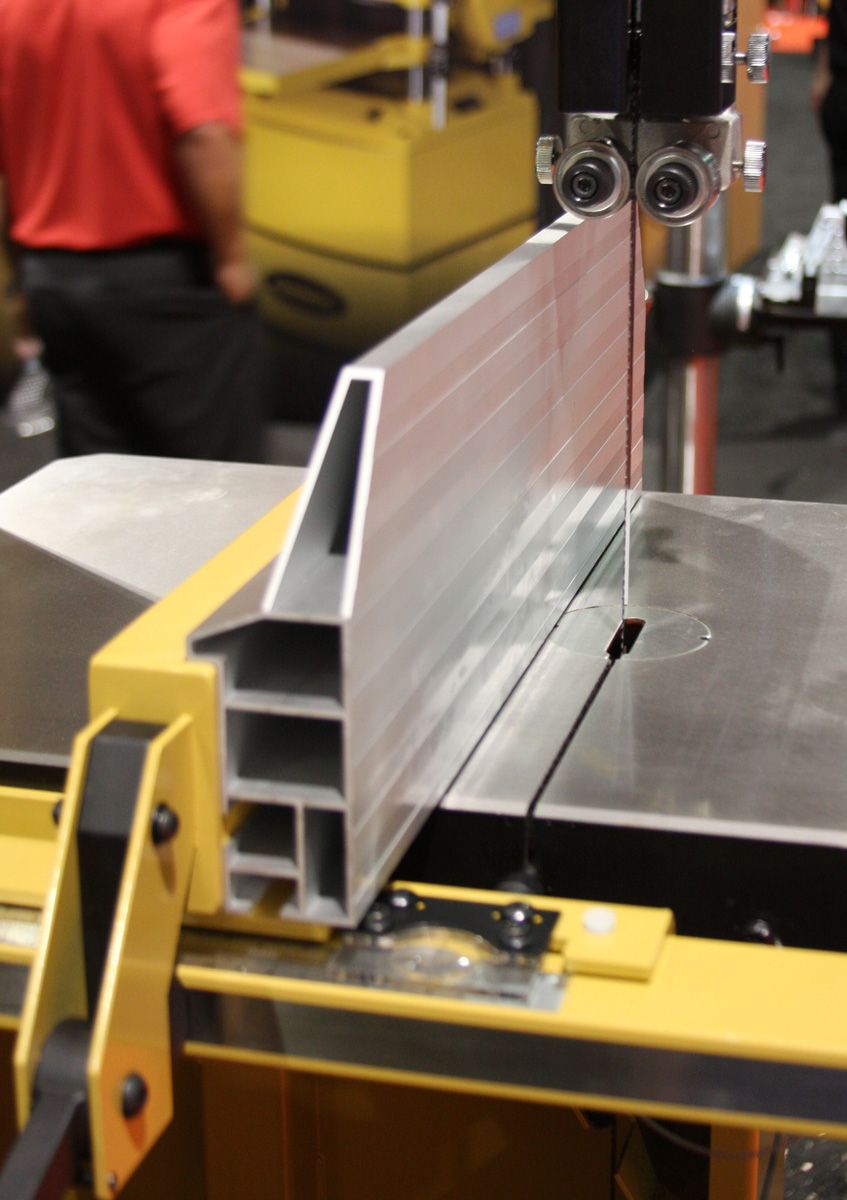

A bandsaw like no other

Schwaiger couldn’t wait to show us Powermatic’s new bandsaw, and it’s easy to see why. The 15 in. saw is a new kind of animal for American tool makers, unlike any other on the market.

Essentially the baby brother of their iconic PM1800 18 in. bandsaw, the new PM1500 features a 3 hp motor and boasts a huge 14 in. resaw capacity. It has a big cast-iron table, a tall resaw fence, bright tires on the wheels to make centering the blade easier, and beefy cast-iron trunnions.

A common procedure for woodworkers is to loosen the tension on the saw when you’re finished with a job, to reduce the stress on the blade. The problem with that is many folks forget to reset the tension before starting the saw a week or two later. That can be dangerous if the blade comes off the wheels once you start the motor. That can’t happen with the PM1500 because the saw won’t start unless the blade has been tensioned. A very smart safety feature.

The PM1500 will be available at the end of the year, says Shwaiger, and will have a street price of around $2,899.

What’s new at Jet?

With Powermatic on a strong path forward, Schwaiger is turning his attention to the Jet brand. Borrowing the successful approach that has invigorated Powermatic, Schwaiger is rethinking the entire Jet line-up, making tough choices on what models to keep and what to eliminate and start over.

In a down economy, that’s a smart approach, as innovative products will stand out among the crowd of tools mired in the status quo. Companies that have been successful in these tough times, such as Festool and Bosch, have been leading the way in product innovation, and Jet hopes to be a leader in innovation as well while keeping its prices in line with the budgets of home shop woodworkers. Toward that end, Schwaiger is refocusing his team on industrial designs that are clean and attractive, and they’re evaluating a number of ideas and models, hoping to make a splash down the road. We’re looking forward to seeing what they have in store.

Comments

Is this new drill press made in China with the crude castings and poor build quality of the original 2800? The new lathe is from Taiwan. I wonder about the new bandsaw? The 1800 is from Taiwan - quite well built!

Why would this band saw be better than the Laguna tools 14" SUV with a 3 hp motor for less money?

I always wanted powermatic equipment and earlier this year I bought the disc/belt combo sander. I have since spent over 15 hours trying to make this equipment run properly. I had to retap holes due to poor threading, grind away poor casting to allow the table to tilt,try to correct extreme vibration and repair poor electricals.

After having the machine eat 6 belts in less that 1 hour run time I discovered I needed to grind down the lead edge of the platen and now I am trying to figure out how to texture the super smooth drive wheel so the belt will not slip as it sands and not crank the belt tension so high that the belts break for another reason.

If they ever want my business again I would suggest they fix the basic poor Taiwanese quality of the current models rather than "Going Big" and creating new problems with new designs!

I bought a Powermatic Contractor table saw several years ago. Why? Because of their reputation. I could not get the blade to stay parallel to the miter slot. Went to the Woodworker's Show. The reps there didn't know what I was talking about. They did give me the phone number of the expert at the Head Office. Nobody there knew what I was talking about. I finally gave it to a guy who didn't care. I bought a Jet Cabinet saw... no problems. Powermatic has found the Detroit auto industry road to profits.

Go BIG is the SECOND most important aspect of the product.

Number ONE is always quality.

I own the PM 2800 drill press and the PM long bed 6" jointer, and while they are both good designs, there is nothing particularly exceptional with either of them regarding quality. In fact, whereas I expected quality to be a discriminator between PM and others, it was NOT.

If the product is made in China or in Chicago makes no difference. Quality is assured by the company, not the vendor. If poorly built products find their way into the market, it is the parent brand/company (I.e. WMH, Delta, Grizzly, General, etc.) that is solely responsible.

When I hear tales of woe regarding "Made in China" I just laugh..........it's the quality ethos of the American company (read: PM/JET) that is responsible for sloppy/low quality products, not a foundry or vendor in China.

If they allow low quality products to define their image in the marketplace, that's what will drive their demise.

I agree with R Herbert completely. I couldn't want a better machine than my 14"

SUV.

odlebob

It will probably still be made over seas. I had a contractor saw for about three months. I had to many problems with it. So I looked for a used Delta and didn't have any problems.It was an American built saw.

I agree with steamliner, all the new "american" equipment is of poor quaility. I've sold all my newer equipment and replaced it with older, quality, american made machines. Powermatic, delta, dewalt, they've all cut corners, sacrificing quailty for profit margins. Its a societal problem, not just limited to this industry.

The older equipment was heavier, and better built, with better motors. I don't have any hands on experience witht the newer euro machines, maybe they have higher standards.

All of these companies shipped the jobs overseas. Now we have less jobs and lesser quality machines. I'm sure the corporate big wigs are doing well though.

Here we go again, who makes the best bandsaw! The Italians or Swedes make the best bandsaw. Which one is best ACM, Hammer or Feldor. Why don't we hear of them in FWW?

You do sometimes. Laguna doesn't make their bandsaws silly wood workers! They have them made for them in China, Tiawan and Italy. You just don't want to pay $3500.00- $4500. for a high-ed bandsaw. So ya plunk down $1500-$2000. and get home to see Tiawan stamped on it then you complain.

You get what you pay for. I suspect (or would hope) this new Powermatic is made by ACM just as Laguna's high-end European saw is.

Myself I found a 12 year old Laguna 18 (ACM) babied and rarely used on Craigslist $600.00. It's from the good old days when Laguna was building it's reputation on quality. If I had to replace it today it will cost about $4,000. from Laguna or Hammer. But guess what? I can order any part I need for my old Italian Laguna from Feldor or Hammer a lot easier and get it faster and cheaper than from Laguna..

So fine woodworking stuff gave up completely on real Jurnalism, all is well in the west and no critical thinking is voiced in the "reporting", the headlines and leaders on the verge of bootlicking. On the other hand we get almost 100% criticism from reader coments. while the truth lies probably somewhere in the middle, maybe some rethinking is required on the magazine side, because maybe the first to go away will be the magazine that should report and not the manufacturers who stunk up. all said, I will be one sorry customer to see you go. a magazine also has product quality, and it is not only measured by the beauty of the pictures.

One would hope that these companies incorporate better dust control into their designs. It is quite obvious that this area has been neglected far too long.

Slowman, this is a live blog, done from the show floor. So there is a bit of excitement mixed in. But nowhere do we report on actual performance, or promise that the manufacturers will actually deliver on their promises. We never say stuff like that unless we have proved in testing. That's where the magazine comes in.

These are all just reports on seemingly hot new tools rolled out at IWF. There is a difference, and I hope it is clear to most people.

Also, what is notable about these latest products from Powermatic is their departure from the recent past. Product designer Barry Schwaiger is a woodworker and wants to return Powermatic to that no-compromises reputation it had in the past. He has taken his time coming out with these latest machines, and asked people to pay for thick castings and state-of-the-art features. What is cool about the new bandsaw is that it is a little brother to the expensive, over-the-top one he came out with two years ago. This one is a much better fit for small shops in my opinion. But we'll have to test it to know for sure, of course, which we will surely do.

So here's the main question. Where IS the PM2800B? They said it would be available at year's end (2012). It's now mid-January 2013 and no sign of it anywhere (including PM's website). ???

I am awaiting it because the YouTube videos of a PM demo brag about the lack of vibration and noise. I wouldn't buy the original 2800 because of soooo many user reviews that complain bitterly about the irritating noise levels and vibration.

So what happened to the fix?

Log in or create an account to post a comment.

Sign up Log in