Morris Chair: Through Mortises

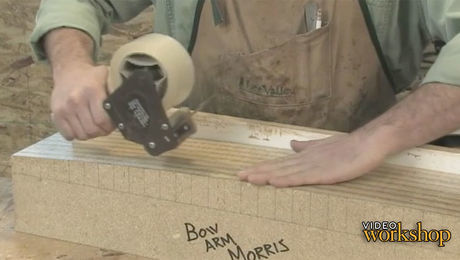

How to cut the through mortises that connect the legs to the bow arms.

Start your 14-day FREE trial to watch this video

Plus, access more than 500 video workshop episodes when you become a member

Gregory Paolini began woodworking in high school and found that he had an affinity for the Arts and Crafts style.

In this video workshop, he’ll show you step-by-step how to make a comfortable Arts and Crafts recliner. For the most part, the construction is straightforward. But the most distinctive part of the chair–its bow arms–presents two big challenges: making a curved lamination, and cutting a mortise-and-tenon joint on the curved arms and side frame.

He’ll show how laminating the arms gets you around those challenges. And he’ll also demonstrate how to get striking quartersawn grain everywhere it counts, including a simple and authentic method for making a leg with four quartersawn faces.

In this episode, Paolini demonstrates how to cut the through mortises that connect the arms to the legs.

Produced by: David Heim; Video by: Gary Junken; Editing by: Michael Dobsevage

Videos in the Series

-

Build A Bow-Arm Stickley Morris ChairAugust 7, 2012

-

Morris Chair: Bending Form for the Bow ArmAugust 7, 2012

-

Morris Chair: Bend the Bow ArmsAugust 7, 2012

-

Morris Chair: Legs with Quartersawn FacesAugust 7, 2012

-

Morris Chair: Router-Cut MortisesAugust 7, 2012

-

Morris Chair: Tenons on the Table SawAugust 7, 2012

-

Morris Chair: Through TenonsAugust 7, 2012

-

Morris Chair: Through MortisesAugust 7, 2012

-

Morris Chair: Constructing the BackAugust 7, 2012

-

Morris Chair: Finishing TouchesAugust 7, 2012

-

Morris Chair: Pivot and Support PinsAugust 7, 2012

-

Morris Chair: Glue Up and Finishing StrategiesAugust 7, 2012

-

Morris Chair: Advice on UpholsteryAugust 7, 2012

Comments

Love Gregory's work and I have always been drawn to Arts & Crafts furniture. Enjoying the videos. Seems like a lot of work to get a bent arm lamination. Would it not be much easier to start with an 2" thick solid arm and bandsaw the bent arm shape to, say, 1" final thickness. The lamination process seems like a lot of work and it shows the individual lams on the side view, not as nice as a solid wood arm.

Log in or become a member to post a comment.

Sign up Log in