Synopsis: See how Greg Klassen crafts the split and bent-laminated back on his side chair.

When Greg Klassen decided to create the curves in his chair by sawing partway down the back legs, steaming them, and bending them apart, he had no idea if it would work. “It was an experiment,” he says. “I thought they might keep cracking all the way down. But I knew I wanted to try.” As it turned out, it worked perfectly—he had no failures. He used ash, a very good bending wood, and it had been air-dried, making it much more amenable to steam-bending than if it had been kiln-dried.

Klassen attached the back legs to the seat rails and stretchers with mortise-and-tenon joints and to the crest rail with dowels. To increase the impact of the Gothic arch created between the two back legs, he moved the rear seat rail forward a few inches and turned it 90° so it lies out of sight in the horizontal plane, leaving the visual flow of the back uninterrupted.

1. Klassen drilled a 1⁄8-in.-dia. hole through an oversize leg blank and bandsawed to the hole. This created a round terminus for the kerf and made the leg less likely to split while it was being bent.

2. After coating the rounded end of the kerf with 3-lb.-cut shellac to slow moisture exchange there, Klassen put the leg into the steambox, leaving it in one hour for each inch of its thickness.

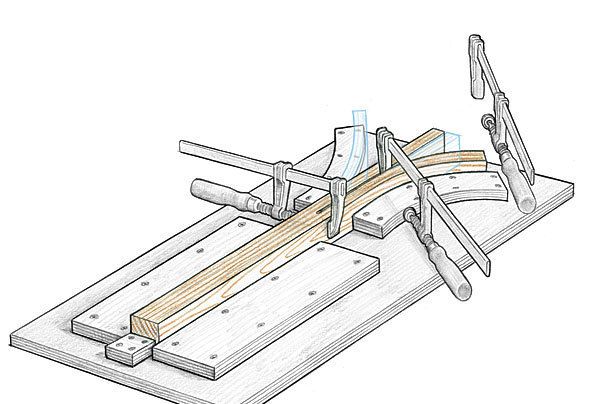

3. Klassen first tightened the clamp at the end of the split, then moved upward clamp by clamp. To minimize springback, he left the leg in the form for several days.

4. Klassen traced a Y-shaped template onto the workpiece. After bandsawing close to the line, he taped the template to the workpiece and flush-trimmed to it at the router table, cleaning up tight spots with a scraper.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in