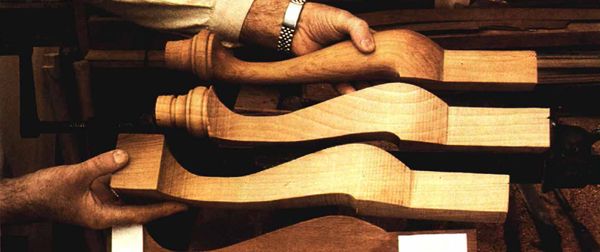

Shaping a Cabriole Leg for a Chair

18th-Century furniture expert Gene Landon explains his simple process of making this classic form using templates and files and rasps to do the shaping.

Synopsis: Making matching cabriole legs seems to require genius, but Eugene E. Landon thinks they’re a breeze to make. Shaping the plain legs for a Queen Anne or Chippendale chair requires only rudimentary skills in spindle-turning and in the use of files, rasps, and scrapers. Landon explains how to prepare the blanks using a template and how to use a half-round rasp and a rat-tail rasp to shape them. He offers side information on how to build a Chippendale chair, and extensive drawings illustrate the process.

Many woodworkers are afraid of cabriole legs. There’s something intimidating about all those graceful interconnecting lines. And making matching pairs seems to require a touch of genius. In point of fact, however, cabriole legs are a breeze. I had my young helper, Joel Crabtrec, feeling guilty for awhile thinking I must have worked incessantly through the night to produce sets of legs for six chairs. Each morning he would find yet another completed set. When he finally discovered I was doing a leg in 20 minutes or so, he felt more sheepish than guilty.

I’m sure craftsmen of the period (1730-1795) worked as quickly. The simultaneous existence of plain and ornately carved styles reflected the European origin and local taste more so than the skill of the woodworker. Economics sometimes dictated the extent of carving; each carved area was charged for separately. Shaping the plain legs for a Queen Anne or Chippendale chair, which I’ll describe later, requires only rudimentary skills in spindle-turning and in the use of files, rasps and scrapers. Figure 1 identifies the parts of the leg and will give you an overall idea of how it is made. The dimensions are for the late Queen Anne, early Chippendale chair shown on p. 86, but the legs can be adapted to different chairs, tables and other furniture pieces.

If you have doubts about your ability to make cabriole legs, 1 invite you to glue up a blank from a cheap, soft wood, such as pine, then go at the job with abandon. There really are not any subtleties or secrets.

Preparing the blank-The leg blanks are in. long (to allow some excess at both ends for later trimming) and in. square. To ensure strength, choose wood without much grain runout. The leg I’m shown making in the photographs is cherry of the worst-working sort—rock hard and brittle. It probably came from a leaning tree. Even so, the job isn’t difficult.

From Fine Woodworking #73

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Starrett 12-in. combination square

Stanley Powerlock 16-ft. tape measure

Suizan Japanese Pull Saw

Log in or create an account to post a comment.

Sign up Log in