How to Model a Woven Seat in SketchUp

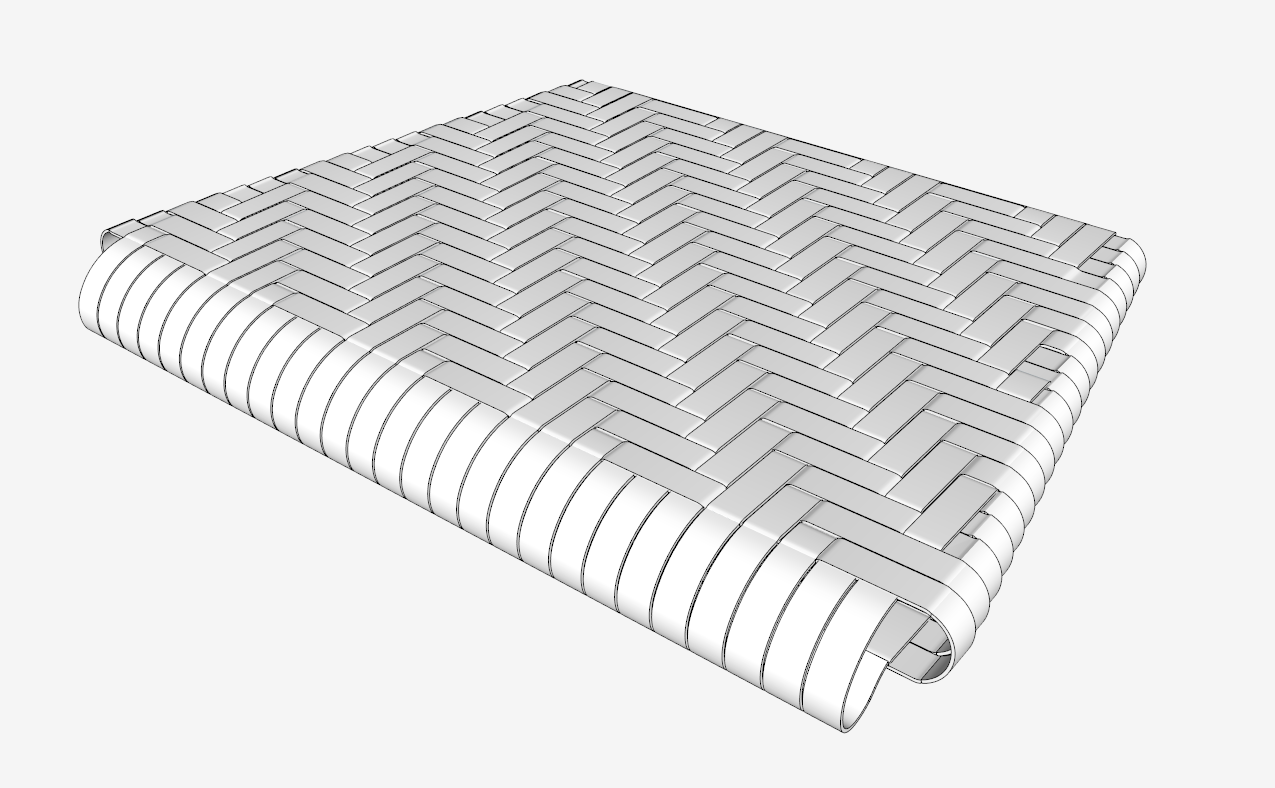

Using SketchUp to create the weaving pattern for an ash splint seat on a Shaker ladderback chair.

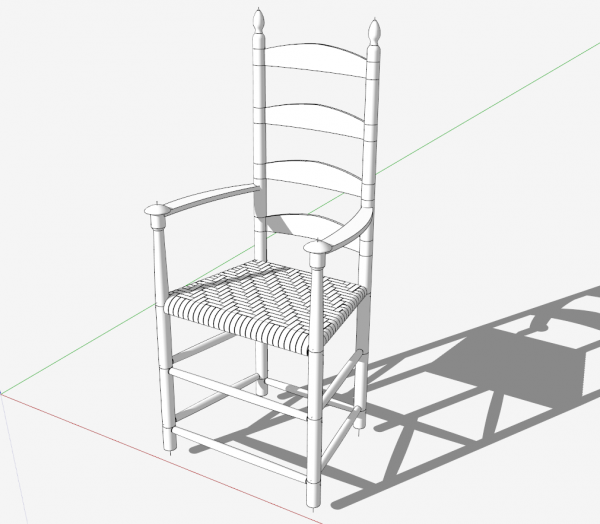

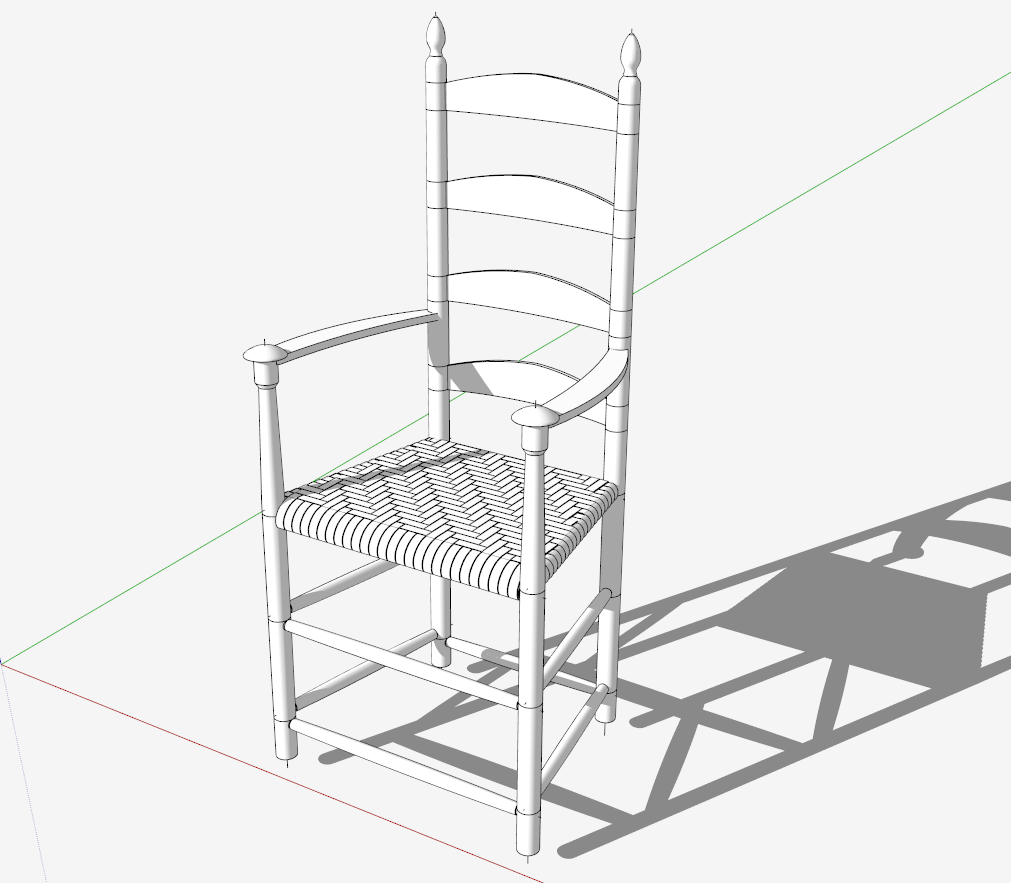

I’ve been building the Shaker Ladderback Armchair in the shop for a couple weeks. The most difficult construction was the ash splint seat. I cut the ash from a local tree about 1/16-in. thick and 5/8-in. wide. Here is the finished piece:

I decided to tackle the SketchUp modeling of the woven seat. I knew that this would be a challenge and learned that it was even more tedious than planned. I usually skip modeling tasks that don’t have a payoff in the shop construction, but this was too enticing. Here is the model with the woven seat.

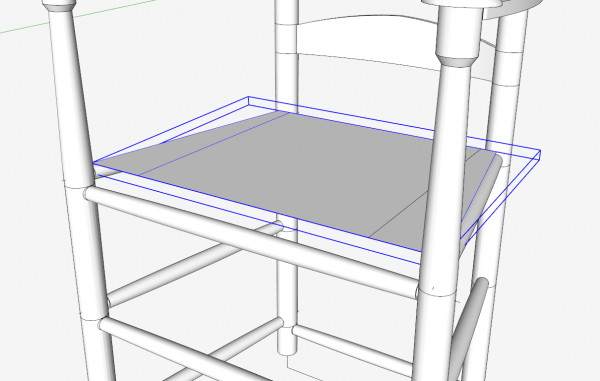

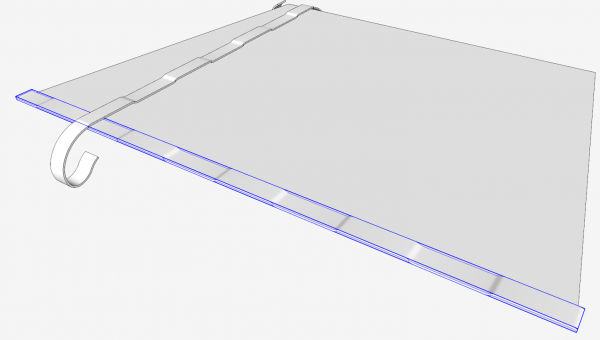

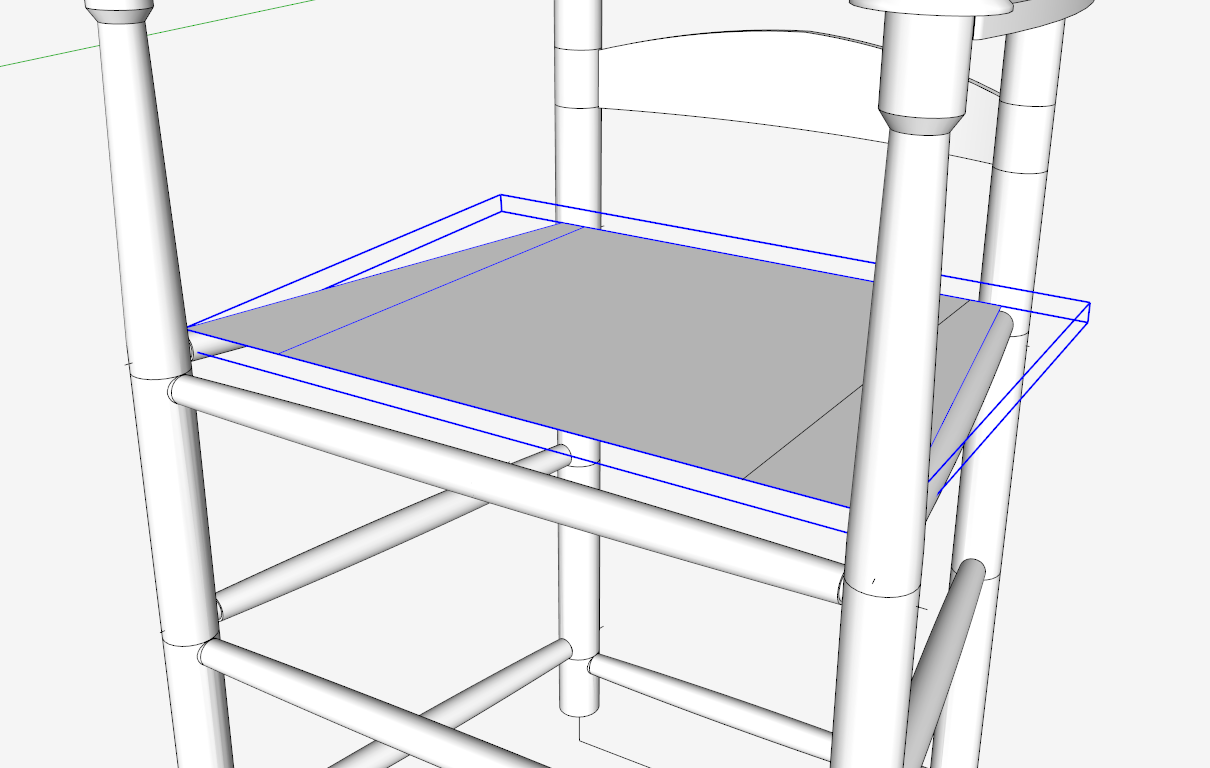

I started the modeling with a flat plate that provided the boundary and the platform for modeling the woven seat.

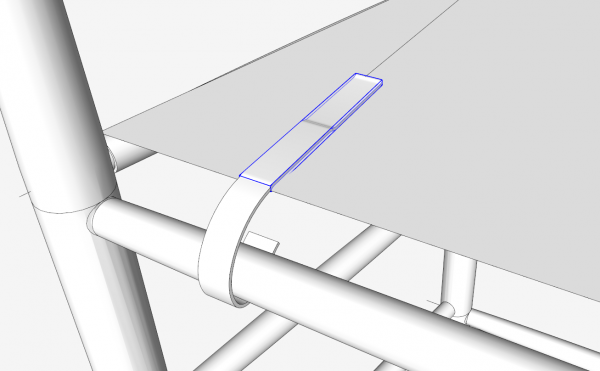

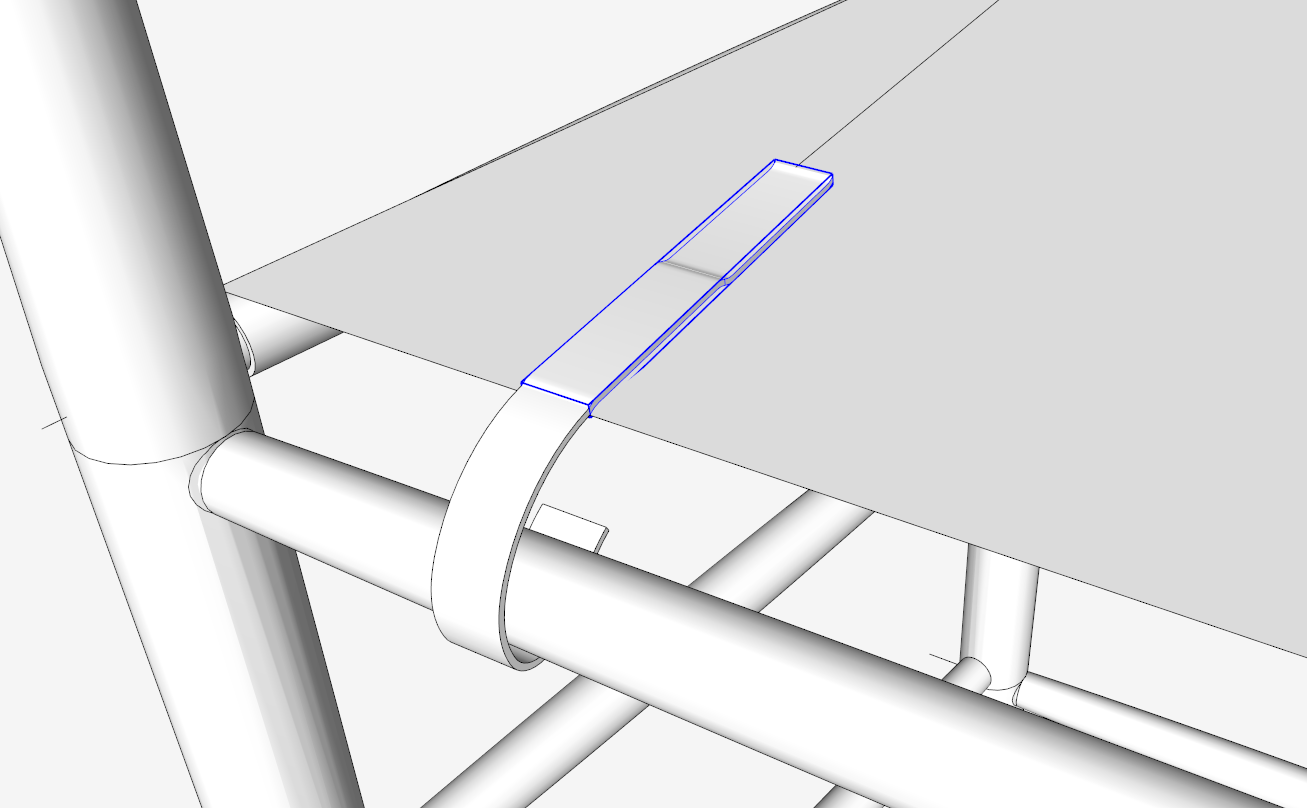

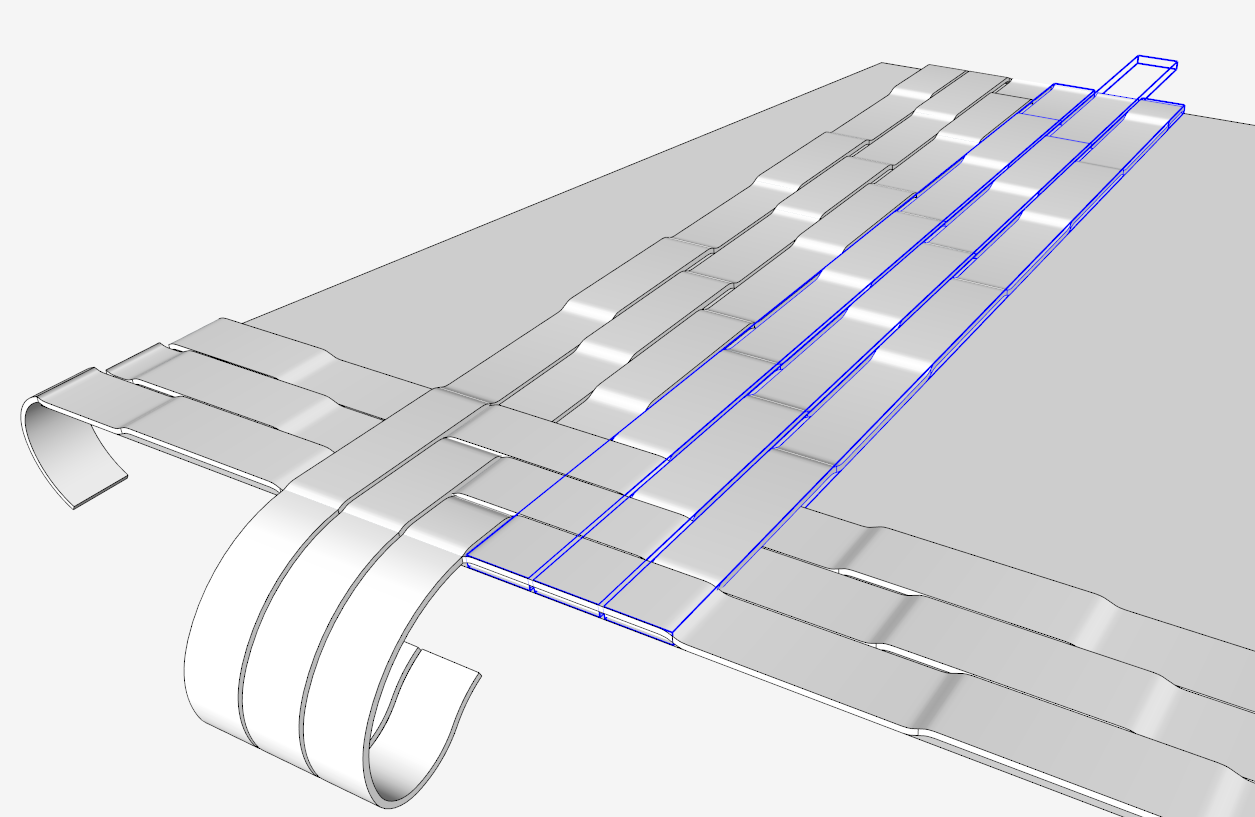

The next step was to create the necessary fundemental building blocks for the seat. First I built the Splint Segment Module that would be copied many times to make-up the ash splints. Also, I roughly made the Loops that connect the top weaving to the bottom weaving. These loops are unique for the front, sides, and back edges.

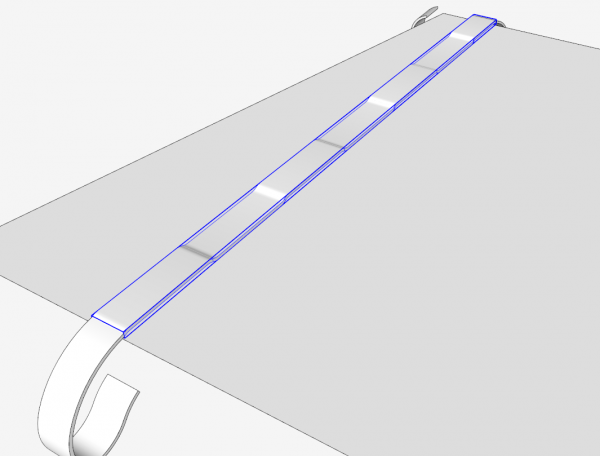

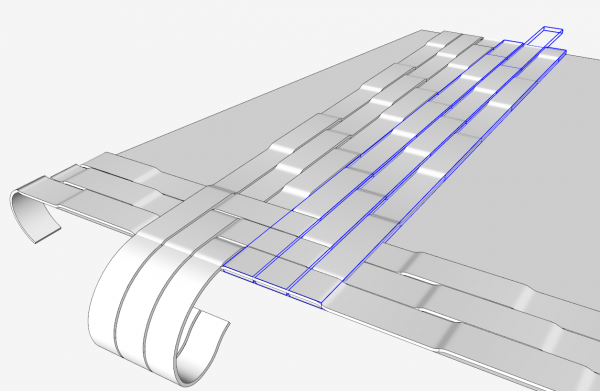

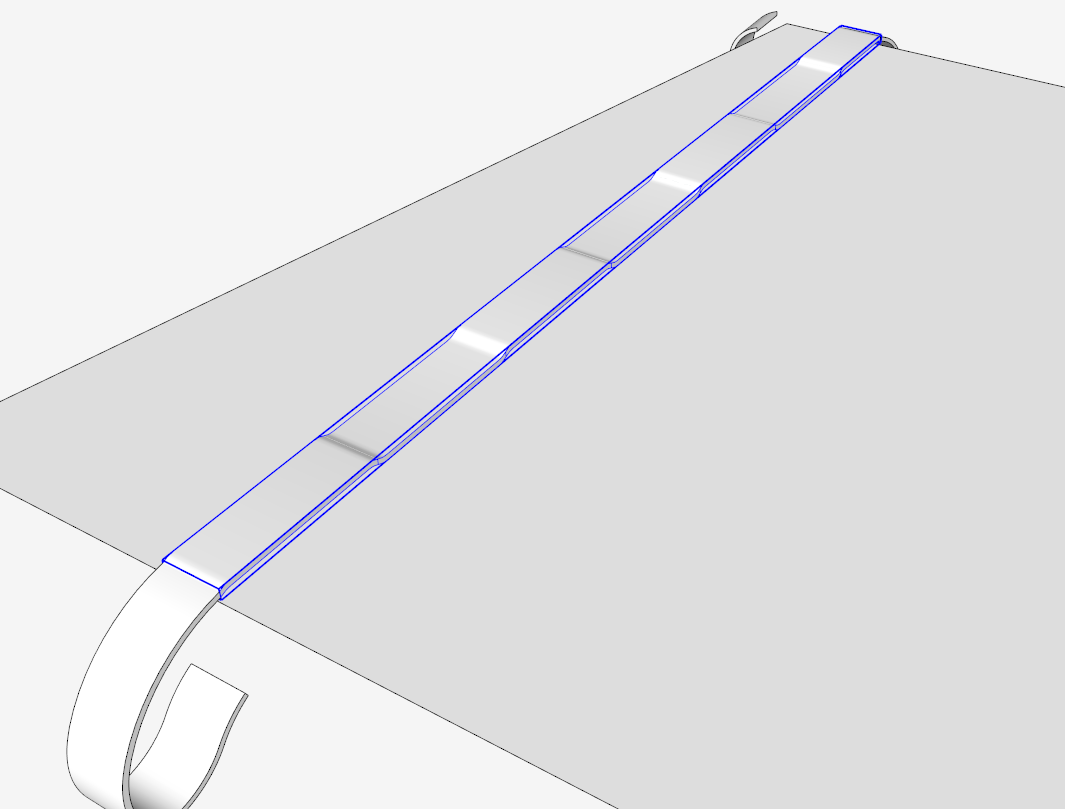

Next I created the first Weft (front to back splint) using several copies of the Splint Module. In the shop I first placed all the warp splints (side to side). But for the SketchUp modeling I worked the wefts and warps together.

My next step was to create the first warp. Note that I am using a 3-over-3 weave in this seat.

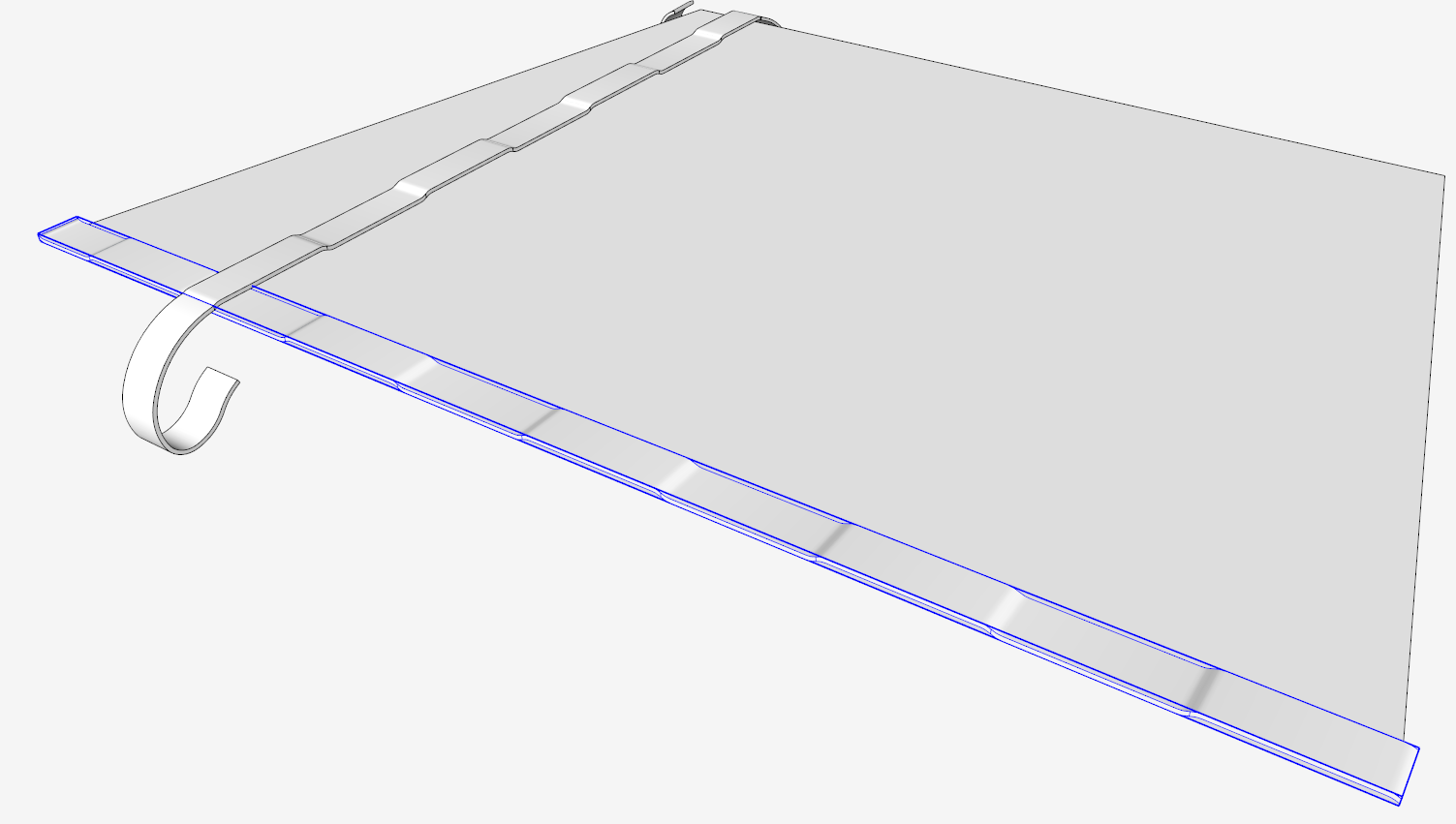

The Wefts are all identical components and that made it easy to copy them to fill out the plate. However, the Warps were all unique in length. So much of tedium was creating these individual splints. Once I had triplets the copying task was accelerated. I could copy three at a time and then flip the three along the blue axis.

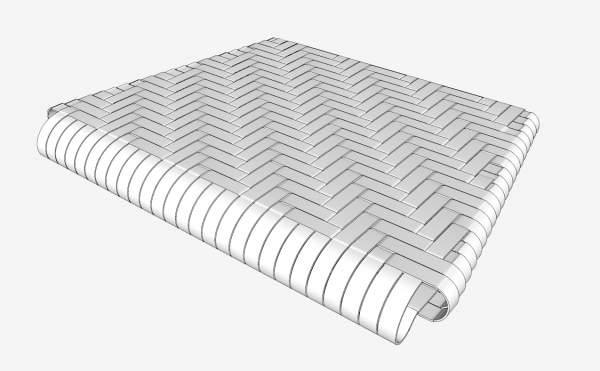

Finally all the parts were assembled including a woven top that was copied to the bottom and flipped.

Here’s the video going through these steps……

Tim

http://killenwood.com

Comments

Rattan and other sort of weaving on furnitures has always been fascinating to me. I saw a few chairs that were woven similarly in a storage unit once and really wanted to know how it was done! Thanks to this, now I do!

Log in or create an account to post a comment.

Sign up Log in