Synopsis: Though most commonly used as the final, protective coating on top of another type of finish, wax has a multitude of other uses. It can be used on its own to serve as a minimal finish and maintain a wood’s natural beauty, or it can give a just-made piece an antique look. It can be colored to create special effects. Finishing expert Peter Gedrys explains how to choose the right wax by understanding the ingredients, how to use colored wax or color your own, how to make an applicator to apply the correct amount of wax, how to achieve a glossy or a satin finish, how to wax intricate shapes or carvings, how to renew a waxed surface, and how to add years to a just-made piece. The tools are simple and the techniques are easy.

There is a quality to a wax topcoat that can’t be matched by more durable, modern finishes. The soft sheen and tactile quality of a waxed surface just begs to be touched. Not only does a waxed surface look good and feel good, but it also helps protect the finish underneath.

There is a quality to a wax topcoat that can’t be matched by more durable, modern finishes. The soft sheen and tactile quality of a waxed surface just begs to be touched. Not only does a waxed surface look good and feel good, but it also helps protect the finish underneath.

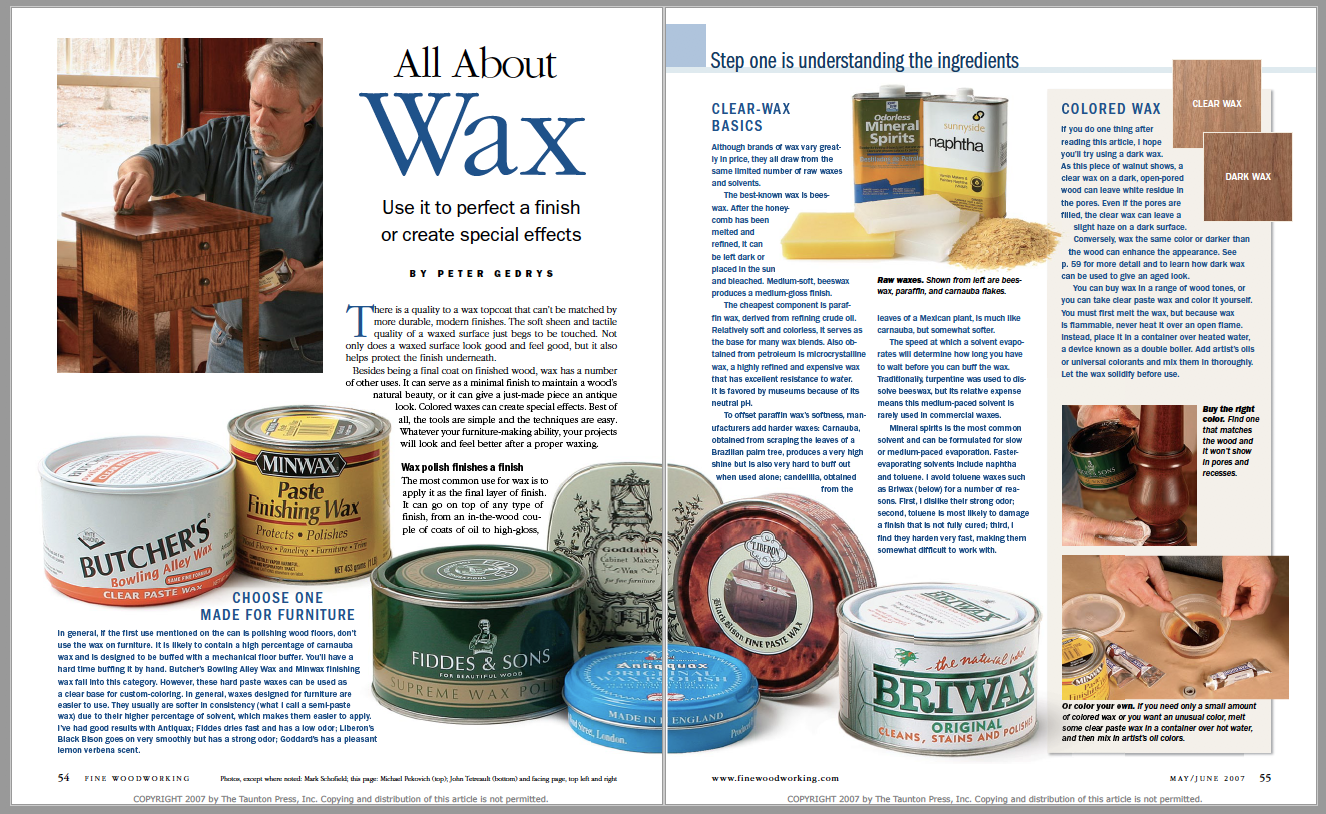

Besides being a final coat on finished wood, wax has a number of other uses. It can serve as a minimal finish to maintain a wood’s natural beauty, or it can give a just-made piece an antique look. Colored waxes can create special effects. Best of all, the tools are simple and the techniques are easy. Whatever your furniture-making ability, your projects will look and feel better after a proper waxing.

Wax polish finishes a finish

The most common use for wax is to apply it as the final layer of finish. It can go on top of any type of finish, from an in-the-wood couple of coats of oil to high-gloss, rubbed-out shellac. The wax helps to even out the sheen and adds a measure of protection that can be renewed easily. However, don’t be in a rush to apply it: Almost all waxes contain solvents, which can damage a film finish that isn’t fully cured. For most finishes, this means waiting a week; but wait at least a month before applying a paste wax to solvent-based lacquer.

For best results, use an applicator—Using widely available but hard paste waxes, beginners tend to put on too much, then wonder why the surface smears when they try to buff it. The answer is to make a wax applicator.

Take some good, dense cheesecloth and fold it over. Place a small amount of wax on the middle of this pad. Gather up the edges and twist them to form a small knob that encloses the wax. As soon as you rub the surface, the wax will start coming through the cloth evenly and thinly. Although you can use softer semi-paste wax this way, you gain the most benefit when using harder paste waxes. For closed-pore, light-colored woods such as maple, I use a clear wax, but for open-pore woods such as oak or mahogany and darker closed-pore woods like cherry, I use a colored wax.

When you rub the surface, you will apply a very thin film of wax. The applicator prevents you from applying too much. I begin by applying the wax in circles, forcing it into any open pores, and then I give it a once-over with the grain to straighten everything out. If you run out of wax, don’t apply more to the outside of the applicator; just unwrap it and replenish the inside.

From Fine Woodworking #191

From Fine Woodworking #191

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Bumblechutes Bee’Nooba Wax

Foam Brushes

Log in or create an account to post a comment.

Sign up Log in