Fuming Wood with Ammonia

Chris Gochnour explains how to darken wood without touching it.

Synopsis: When you see wood that has been stained or dyed, you know right away that it’s been stained or dyed. But fumed wood looks natural, as if it came from the tree with that dark, rich color. Chris Gochnour explains what you need to do to fume wood with ammonia and how to make a vaporproof tent to house the fuming process.

Using ammonia fumes to alter and enrich wood’s natural color, a process called fuming, has been a staple of woodworkers for centuries. Its effect is quite distinct from other coloring techniques. When you see wood that has been stained or dyed, you know right away it’s been stained or dyed. But fumed wood looks natural, as if it came straight from the tree, but with a darker, richer color. I have been fuming furniture for more than 30 years and love the natural, honest, and woody tones it imparts.

Ammonia fumes react with the natural tannins in certain wood species to deepen the wood’s color and enliven the figure. Woods high in tannin—such as white oak, beech, and butternut—respond best to this treatment. The ammonia fumes penetrate the wood uniformly and deeply (to a depth of about 1/8 in.), so fumed pieces can be sanded without fear of sanding through the coloring.

What you need to get started

Fuming requires ammonia, plastic containers, and a fuming chamber. Since household ammonia is fairly weak at only 5% to 10% ammonia, I use a commercial aqueous ammonia (also known as aqua ammonia or ammonium hydroxide) that is a potent 25% ammonia mixed with water. You can purchase commercial-grade aqueous ammonia online, or at some janitorial supply stores.

In this video we compare fuming with

three different strengths of ammonia

I use plastic containers to hold the ammonia and build a vaporproof tent, or chamber, to house the fuming process. I typically build the frame out of wood and wrap it in clear polyethylene sheeting. I’ve used a 5-gal. bucket to fume small pieces. For really large pieces, I’ve portioned off a section of my finish room with wood framing and polyethylene tarps. I once did this to fume a dining table and eight chairs all at once. My finish room’s fan made it ideal for venting the fumes when the process was complete.

From Fine Woodworking #282

To view the entire article, please click the View PDF button below.

|

The best ammonia for fuming white oakwith Ben Strano |

|

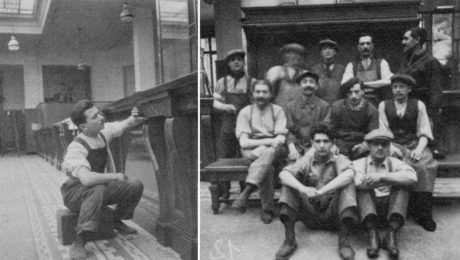

Finish Line: Original Arts and CraftsSEPTEMBER 1, 2007 |

|

Adventures in Woodworking–Fernan Banks On AmmoniaMARCH 25, 2020 |

Fine Woodworking Recommended Products

Odie's Oil

Diablo ‘SandNet’ Sanding Discs

Bumblechutes Bee’Nooba Wax

Comments

What about disposal of the ammonia after use?

Hi, I want to use ammonia to react my oak kitchen furnitures but have listen that with the time may appear stains because ammonia could react in the future with the varnish used or even with different liquids that can fall down in the furnite, creating new reactions with this. Is it possible from your experience?

Log in or create an account to post a comment.

Sign up Log in