Lather Up: Soap-Flake Finish

Pure soap flakes produce a beautiful finish.

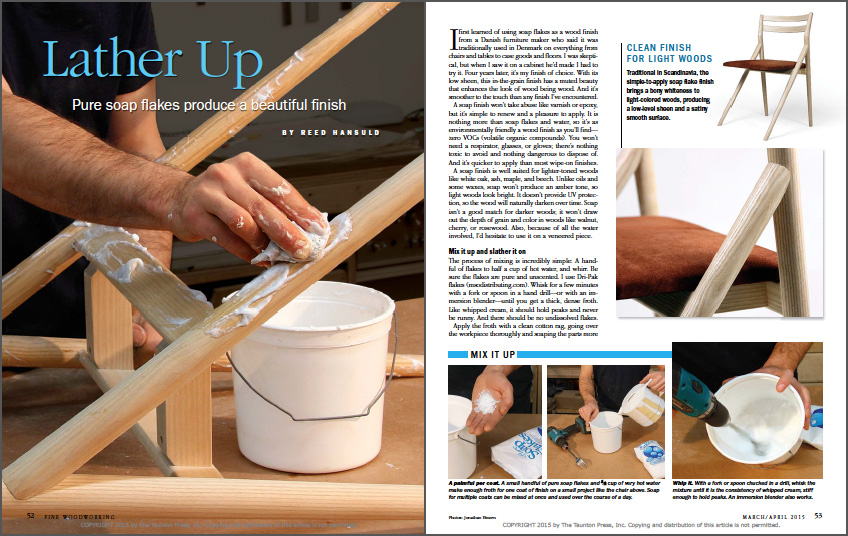

Synopsis: A traditional finish on Danish furniture, soap has a low sheen, in-the-grain quality that enhances the natural look of wood. It’s also very easy to use. All you need is a handful of pure soap flakes and 1/2 cup of hot water. This bright, light finish is ideal for lighter-toned woods like white oak, ash, maple, and beech.

I first learned of using soap flakes as a wood finish from a Danish furniture maker who said it was traditionally used in Denmark on everything from chairs and tables to case goods and floors. I was skeptical, but when I saw it on a cabinet he’d made I had to try it. Four years later, it’s my finish of choice. With its low sheen, this in-the-grain finish has a muted beauty that enhances the look of wood being wood. And it’s smoother to the touch than any finish I’ve encountered.

A soap finish won’t take abuse like varnish or epoxy, but it’s simple to renew and a pleasure to apply. It is nothing more than soap flakes and water, so it’s as environmentally friendly a wood finish as you’ll find— zero VOCs (volatile organic compounds). You won’t need a respirator, glasses, or gloves; there’s nothing toxic to avoid and nothing dangerous to dispose of. And it’s quicker to apply than most wipe-on finishes.

A soap finish is well suited for lighter-toned woods like white oak, ash, maple, and beech. Unlike oils and some waxes, soap won’t produce an amber tone, so light woods look bright. It doesn’t provide UV protection, so the wood will naturally darken over time. Soap isn’t a good match for darker woods; it won’t draw out the depth of grain and color in woods like walnut, cherry, or rosewood. Also, because of all the water involved, I’d hesitate to use it on a veneered piece.

Mix it up and slather it on

The process of mixing is incredibly simple: A handful of flakes to half a cup of hot water, and whirr. Be sure the flakes are pure and unscented. I use Dri-Pak flakes (msodistributing.com). Whisk for a few minutes with a fork or spoon in a hand drill—or with an immersion blender—until you get a thick, dense froth. Like whipped cream, it should hold peaks and never be runny. And there should be no undissolved flakes.

Apply the froth with a clean cotton rag, going over the workpiece thoroughly and soaping the parts more than once per coat. Then go over the piece with a fresh rag, removing excess suds and really buffing the finish into the wood. At this point I rinse out the buffing rag and hang it to dry with the rinsed application rag. Both can be reused for the next coat.

In an hour or so, when the work is dry, do a light sanding. After the first coat or two I use 220-grit, and after subsequent coats I work upward to 600-grit or higher.

The finish should be renewed every year or so. Stains can be spot-treated by rubbing the stained area with very hot water and recoating with soap froth. If the stain persists, scrape or sand through to clean wood before applying the froth.

From Fine Woodworking #246

To view the entire article, please click the View PDF button below.

Fine Woodworking Recommended Products

Osmo Polyx-Oil

Bahco 6-Inch Card Scraper

Diablo ‘SandNet’ Sanding Discs

Log in or create an account to post a comment.

Sign up Log in