The Best Ammonia for Fuming White Oak

This test compares the effectiveness of household, janitorial, and industrial-strength ammonia.

Since household ammonia is fairly weak at only 5% to 10% ammonia, contributing editor Chris Gochnour uses a commercial aqueous ammonia (also known as aqua ammonia or ammonium hydroxide) that is a potent 25% ammonia mixed with water to fume his white-oak projects. You can purchase commercial-grade aqueous ammonia online, or at some janitorial supply stores. Fine Woodworking creative director Mike Pekovich has been using janitorial-strength ammonia (10%) to fume his projects for years. It’s a bit easier to locate, assuming you are within driving distance to an Ace Hardware, the only place either of us have been able to find it. On the other hand, household-strength ammonia is incredibly easy to find. Over the last couple of weeks I paid attention, and I was able to find it at every grocery store and hardware store I went to.

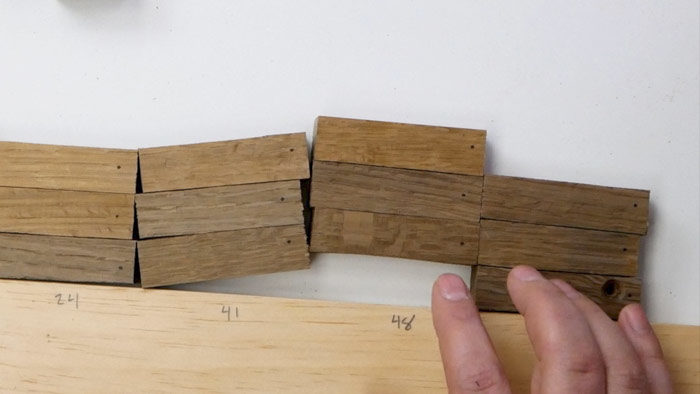

For this test, I started with three resealable containers. In each, I placed equal amounts of each concentration of ammonia, and eight pieces of oak, all cut from the same board. At designated intervals, I pulled one piece out of each container and labeled it. I changed out the ammonia for a fresh batch every 24 hours.

After 72 hours

In my potting shed, where I was running this experiment, the pieces seemed to hit their full concentration after 72 hours. After bringing everything inside, a part of me wishes that I let the experiment run one more day. That said, in my entirely non-scientific experiment, I feel like we got some fairly interesting results.

I had heard that weaker ammonia can cause some oak to have a little bit of a green cast. In my experiment, the differences in color were indiscernible to me. As expected, the weaker strength ammonia just took longer to darken the oak.

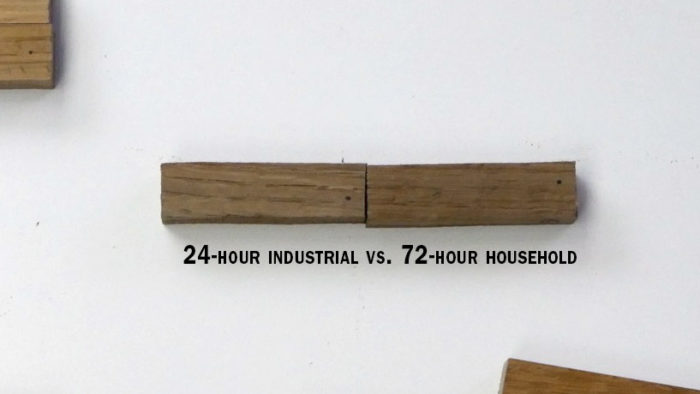

The darkness of the 48-hour janitorial sample matches the 72-hour household sample. Same for the 48-hour industrial sample and the 72-hour janitorial.

More than skin deep

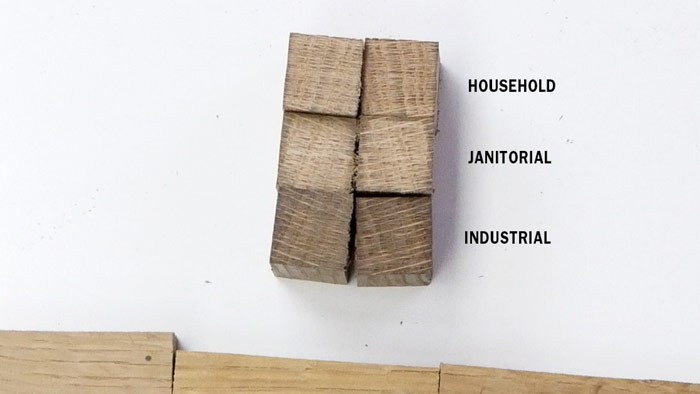

Many woodworkers prefer fuming with ammonia because the color goes deeper into the wood, making it a non-issue if you have to sand or plane a piece after fuming. This is where my experiment got really interesting. After 72 hours, the household strength reached about a 1/16 in. beneath the surface, janitorial about 1/8th in. deep, and the industrial sample had full penetration. If you are looking for color that runs deeper beneath the surface, I would reach for janitorial or industrial strength.

Comments

Ben, a great video that offers insight I did not have around the penetration levels!

Thanks for showing the block sample comparisons of strength to the duration of exposure.

It appears the industrial-strength over a long exposure time will work for me.

Ammonium Chloride is available from Amazon for about $3 a pound. Sodium Hydroxide too, though it costs more, at least partly because it is caustic. But you can get it at a hardware labeled as drain cleaner or lye.

Mix them in a dish and add a couple of spoons of water. It foams with ammonia gas and also produces some table salt and some water. The water keeps the reaction going without adding more water.

I've done this a couple of times and will not willingly go back to liquid.

My results look as good or better, allowing for the photographs reproducing colors and the finish on my example, as the industrial results in the article.

When I need more lye I think I'll ask home soap makers where they get it.

Hi Ben,

I'm a Ph.D. chemist. Ammonia is serious stuff and deserves all the respect and safety precautions you mention.

Out of curiosity, could you please take some oak and wipe the three stengths of ammomia on it? Curious if that greatly speeds up the process. Yes, it would raise grain.

Thanks,

Joe

That's a cool idea. I'll try and get to that this week.

Ben, Great article thanks much for posting this, gives me great insight into the timelines and penetration depth of Fuming. Thanks again.

Hey Ben - great vid. A couple of comments here. First, I've been doing fuming with hardware store ammonia for years. It's easy, relatively quick, and safe. I remember the reagent grade stuff from my university days. Yes - it's very nasty - but for wood working, unnecessary. If you want the hardware store or grocery store stuff to work a bit faster, put an incandescent light bulb under the tent to warm it up a bit. Next, there is no good reason, especially with a smaller enclosure, to renew the ammonia periodically. The air inside the enclosure will come to an equilibrium with the NH3 gas. And finally, all the respirator stuff is not necessary for the weaker solutions. Yes, it stinks, and yes it stings your eyes, but it's not really that dangerous. Obviously, it is extremely unwise to splash it on your face, but that's the case with many other products we use in the shop every day.

Attached is an important example!

I'm curious, please explain the image.

Sure thing. It's an English beer engine (hand pump) housed in an ammonia-fumed white oak tower I built for the bar. It is used to dispense my beer from the casks in the cellar. (Only of course, after the power tools are shut down for the day!)

I'll be over this afternoon for happy hour.

The door's open, bud!

Hi Ben,

Have you had a chance to try it out yet (wiping some oak with ammonia)? Just curious.

By the way, the mini-podcast you and Mike did came out fine from my listening perspective. Had you not mentioned there were challenges, I'm not sure I would have noticed. Of course, I listened to it while I was working in my shop.

I haven't yet. Been busy! That podcast didn't sound challenging because I worked my butt of in the edit!

Er, What, exactly, did you, [ ... Work[ed] your butt of" -Mr. Editor?

What goes, "struggle, struggle,struggle, thud."?

Answer: Ben editing his butt off!

Very informative and good advice to boot! Nice job

Nicely done and very informative.

As an alternative to working with toxic chemicals, we have a product called Fumed. Is gives the reaction of Fuming wood but without the chemicals. It gives an aged-grey look by reacting with tannins in the wood. Check out the application video on the product page to see how simple it is.

https://rubiomonocoatonline.com/products/fumed

Ben, two words: swim goggles.

I drove a truck 50 years ago delivering industrial Ammonia, Chlorine and some other bad boys and I have no recollection as to how strong our Ammonia was. However we were always told our job was only to move the container from the truck to the dock and never change out a container for a costumer or touch one that was leaking as that required a full face mask and air supply. My 2 cents.

The stuff you were delivering was anhydrous ammonia. It was 100% NH3 compressed to a liquid form, transported and stored under pressure. While it will certainly fume white oak, it is *extremely* dangerous to handle. The "ammonia" used in this video is a solution of NH3 and water at various concentrations - technically ammonium hydroxide. It liberates free NH3, (ammonia), when exposed to air.

Great article and video! Is there another chemical that whitens the oak in similar fashion, not just a surface stain. Any suggestions are highly appreciated. If someone does another article and video on this topic would be truly awesome!

Bam! https://www.finewoodworking.com/2017/07/06/try-a-bleached-finish

Love it. Is there any chance you have any real English Brown Oak to compare it to? Also, does fuming work on other woods? I've used sodium bicarbonate to darken Utile, but it isn't always easy to get a consistent finish. I like the darker color though.

Enjoyed the video Ben. I tried/tested this myself this week. I used just the janitorial and my results were quite a bit different than yours. I'm not questioning your results but my results showed what appears to be 100% penetration using the janitorial ammonia (from Ace, which says 10%). I started with a few samples in a large tote (64 qt), using apoximately 2 cups of ammonia in one of those disposable Tupperware containers about the size of a quart ziploc bag. The tote lid is not sealed with foam or anything but it is a relatively good seal. After 11 hours I pulled out a sample and my results were in the color range of your samples from the janitorial ammonia after 41 hours. After 20 hours it is a shade darker, maybe where yours were after 48 hours. I'm starting over and going to check every couple hours. On inspection after cutting the samples open it looks to me that the color goes 100% through (the samples are between 3/4" and 1 1/4").

Might have to do that it is warmer here then where/when you performed this test or you opened or had lower ratio of ammonia by volume to the cubic volume of your chamber.

As for the question about rubbing it on the wood. I didn't try that exactly but I did splash a bit on one of the test pieces and I can't see where I did. I also don't like the idea of that process so I don't see much point in that question after my testing. Even the Janitorial concentration is pretty darn strong and this look like it would accomplish the task at hand easily. Now I just have to get the shade I like, but I feel even in the production setup I will need to check it occasionally.

Second note if your piece has different shades (didn't come all from the same tree) in it the effect of fuming definitely seems to exasperate this (probably more so than staining). This could be an issue or a challenge.

Disclaimer about the image attached. It has one coat of Osmo Polyx Oil - 3054) and will look a bit richer with 2 coats I imagine.

One caution that is missing from this and other similar videos; a respirator needs to be fit-tested. There is a procedure using methyl butyl, or similar, to see if there is a complete seal. Without the seal, it is not much more than a mask. They will never fit properly over facial hair - can't make the seal.

Anything but a proper fit is a possibly dangerous delusion. Be safe.

Great safety follow-up.

When I hauled "Haz-Mat", the seal was tested with Banana Oil. [Put the mask on, clear it and then someone would open a container of the odiferous oil out of your sight. If you were able to smell it you were not protected.] I had [and still have] a full beard - the same one I started when I completed my active duty in 1962. I offered to buy my own fully self contained respirator, but "Corporate" decided that would set a "Bad" precedent. I walked away after training my replacement. No one "Owns" me. [On a current issue, use something like Listerine to test your "Compliance" mask. If you can't smell it through the mask, the mask works. Otherwise ...

Methyl Butyl is synthetic banana flavor, what they still use. There have been a few people with facial hair pass the fit test, but unless your grooming is perfectly consistent, the fit can't be guaranteed.

Thanks for doing the haz-mat work - so we can have all the nasty stuff we need each day.

Log in or create an account to post a comment.

Sign up Log in