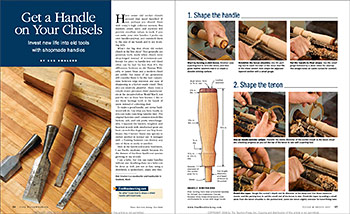

Get a Handle on Your Chisels

Invest new life into old socket chisels with shopmade handles.

Synopsis: There are premium chisels out there at flea markets, estate sales, and auctions–provided you know how to make your own handles. Bob Smalser demonstrates how to make a simple shopmade handle that will turn a used tool into a valuable addition to your workbench. Step-by-step instructions show how to use a lathe to shape the handle and the tenon, sand and finish the handle, and fit it and set it into the tool.

Have some old socket chisels around that need handles? If not, perhaps you should. Even with today’s high collector interest, flea markets, estate sales, and auctions still provide excellent values in tools if you can make your own handles. I prefer my own handles anyway, as I custom-fit them to the size of my hands and to my working style.

What’s the big deal about old socket chisels in the first place? They generally are premium tools, made when chisels were drop-forged instead of investment-cast. Except for price (a handle-less old chisel often can be had for less than $5), the differences between an old Thomas Witherby or James Swan and a modern chisel are subtle, but many of my generation still consider them to be the best compromise between edge retention and ease of sharpening in a factory-made chisel. They also are relatively plentiful—there were a couple dozen premium chisel manufacturers in the decades before World War II, not just the two or three best known. I like to see those heritage tools in the hands of users instead of collecting dust.

To make a good handle, any dense hardwood will do. Use what you have locally so you can make matching handles later. The original factories used common woods like hickory, ash, and oak pretty interchangeably. I suppose the hardest, toughest, and heaviest woods with interlocked grain are best—woods like dogwood and hop hornbeam—but I haven’t found one species to outlast another in normal use. A teenager with a framing hammer can destroy any one of them as easily as another.

Here in the hardwood-scarce Northwest, I use Pacific madrone, simply because it’s the densest of the three hardwood species growing in my woods.

I use a lathe, but you can make handles without one. Anything done on a lathe can be done as well, just not as fast, using a drawknife, a spokeshave, rasps, and files.

From Fine Woodworking #188

From Fine Woodworking #188

To view the entire article, please click the View PDF button below:

Fine Woodworking Recommended Products

Tite-Mark Marking Gauge

Stanley Powerlock 16-ft. tape measure

Veritas Micro-Adjust Wheel Marking Gauge

Log in or create an account to post a comment.

Sign up Log in