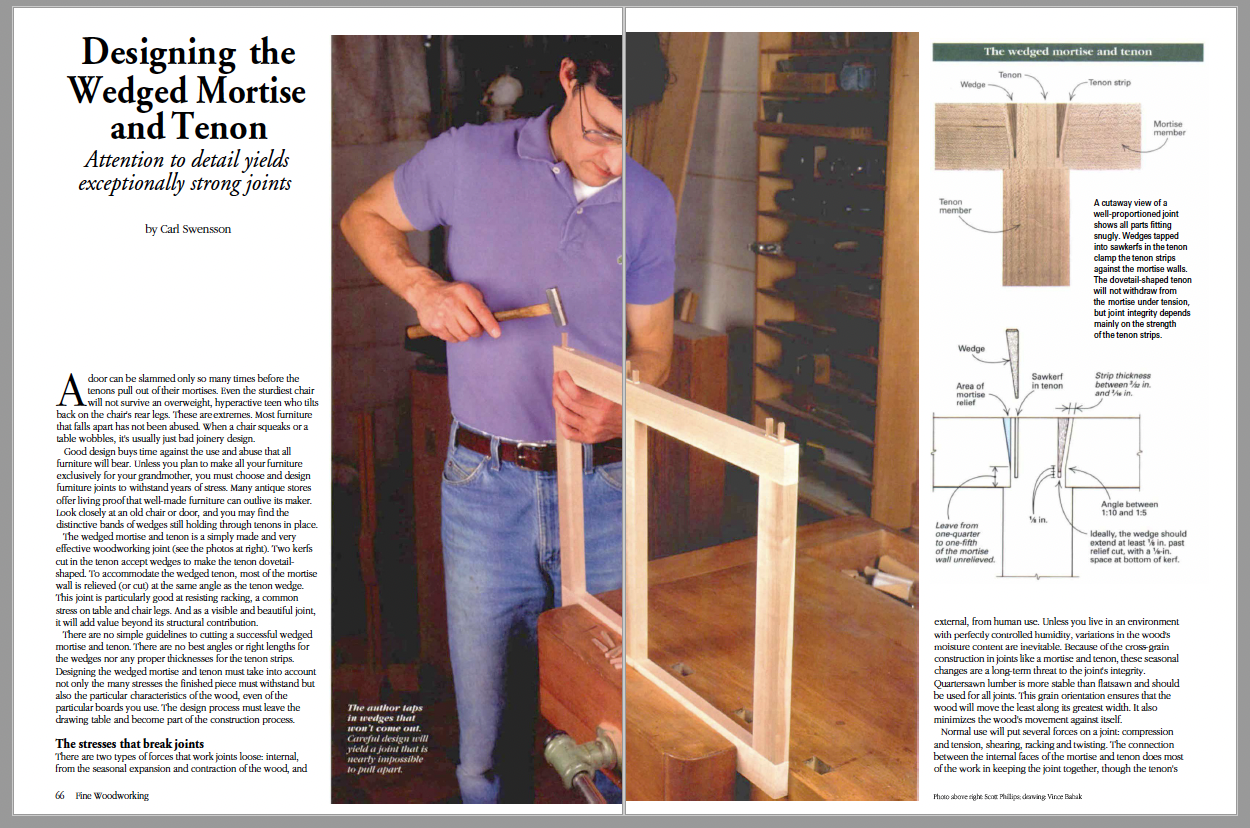

Designing the Wedged Mortise and Tenon

Attention to detail yields exceptionally strong mortise-and-tenon joints.

Synopsis: When a table wobbles or a chair squeaks, it’s usually just bad joinery design, says Carl Swensson. Good design buys time against use and abuse that all furniture bears. The wedged mortise and tenon is simply made and very effective. He talks about how there are no simple guidelines to cutting a successful wedged mortise and tenon, and he outlines the stresses that break joints. He says quartersawn lumber should be used in all joints, and he addresses grain orientation. Wedge the tenon against the tension the piece is expected to have and use templates to test thicknesses and angles. He describes proportions for mortise wall relief and tenon kerf, and how to ensure a successful final assembly.

A door can be slammed only so many times before the tenons pull out of their mortises. Even the sturdiest chair will not survive an overweight, hyperactive teen who tilts back on the chair’s rear legs. These are extremes. Most furniture that falls apart has not been abused. When a chair squeaks or a table wobbles, it’s usually just bad joinery design.

Good design buys time against the use and abuse that all furniture will bear. Unless you plan to make all your furniture exclusively for your grandmother, you must choose and design furniture joints to withstand years of stress. Many antique stores offer living proof that well-made furniture can outlive its maker. Look closely at an old chair or door, and you may find the distinctive bands of wedges still holding through tenons in place.

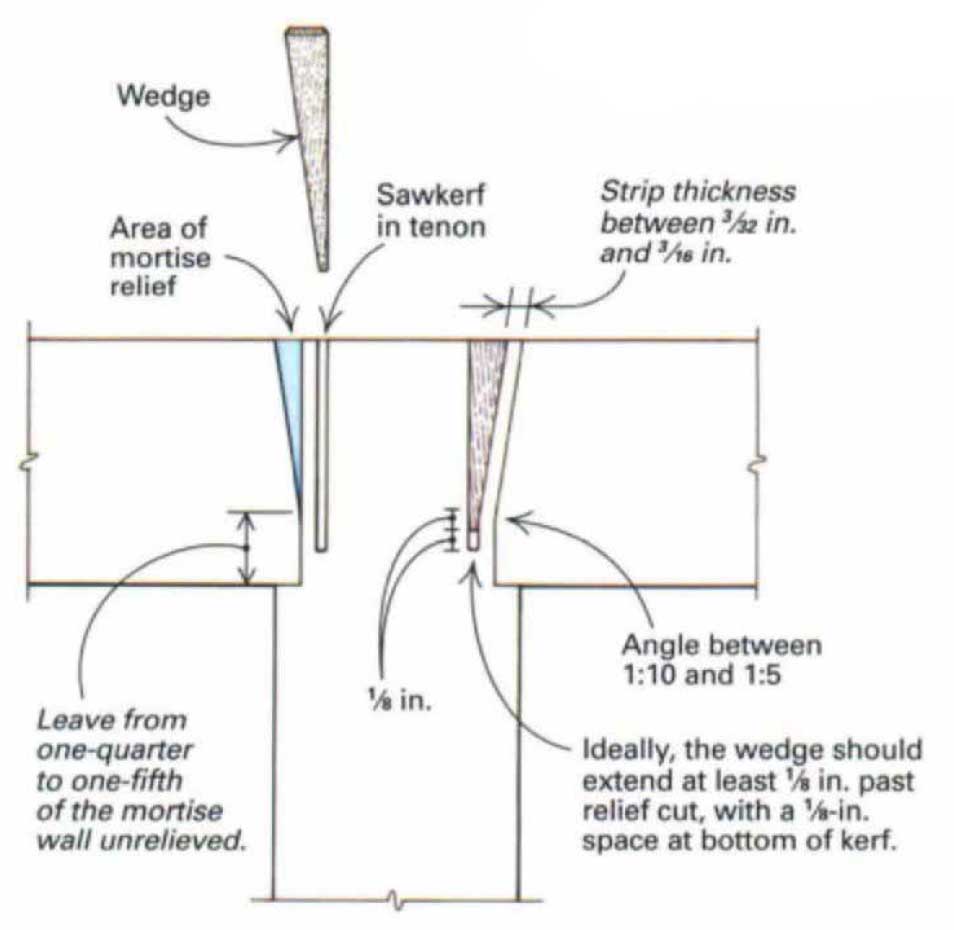

The wedged mortise and tenon is a simply made and very effective woodworking joint. Two kerfs cut in the tenon accept wedges to make the tenon dovetail-shaped. To accommodate the wedged tenon, most of the mortise wall is relieved (or cut) at the same angle as the tenon wedge. This joint is particularly good at resisting racking, a common stress on table and chair legs. And as a visible and beautiful joint, it will add value beyond its structural contribution.

There are no simple guidelines to cutting a successful wedged mortise and tenon. There are no best angles or right lengths for the wedges nor any proper thicknesses for the tenon strips. Designing the wedged mortise and tenon must take into account not only the many stresses the finished piece must withstand but also the particular characteristics of the wood, even of the particular boards you use. The design process must leave the drawing table and become part of the construction process.

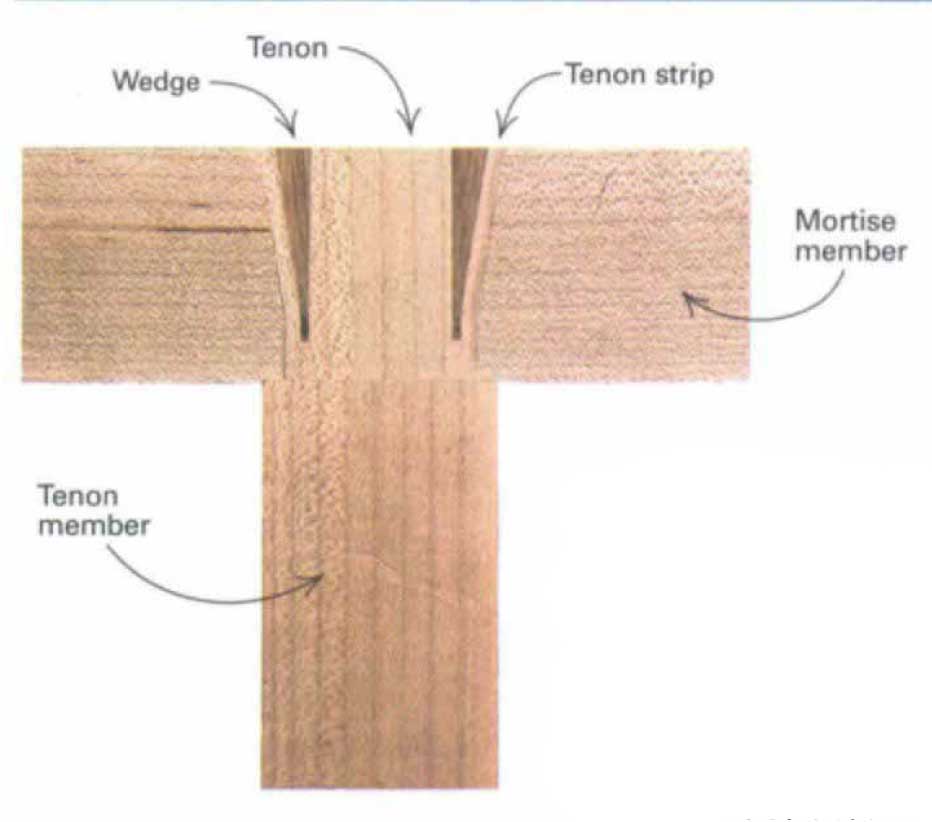

The Wedged Mortise and Tenon

A cutaway view of a well-proportioned joint shows all parts fitting snugly. Wedges tapped into sawkerfs in the tenon clamp the tenon strips against the mortise walls. The dovetail-shaped tenon will not withdraw from the mortise under tension, but joint integrity depends mainly on the strength of the tenon strips.

|

The stresses that break joints There are two types of forces that work joints loose: internal, from the seasonal expansion and contraction of the wood, and external, from human use. Unless you live in an environment with perfectly controlled humidity, variations in the wood’s moisture content are inevitable. Because of the cross-grain construction in joints like a mortise and tenon, these seasonal changes are a long-term threat to the joint’s integrity.

From Fine Woodworking #124

From Fine Woodworking #124

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Pfiel Chip Carving Knife

Stanley Powerlock 16-ft. tape measure

Sketchup Class

Log in or create an account to post a comment.

Sign up Log in