How to Cut Stopped Dadoes on the Table Saw

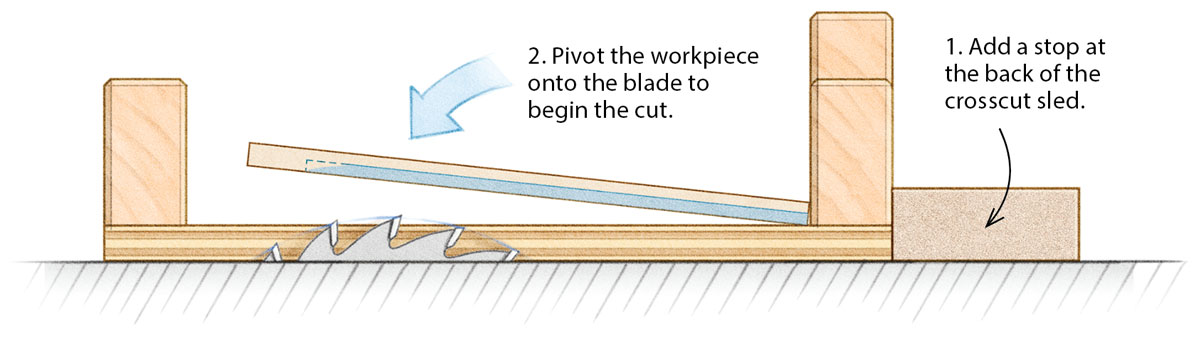

Mike Pekovich uses a crosscut sled and stop blocks to cut stopped dadoes safely.

Stopped dadoes on the tablesaw

Pekovich uses a crosscut sled for the stopped dadoes in the case sides. In order to register all parts against the same side stop, he cuts half the dadoes so the stopped end is at the front of the sled and the other half so the stopped end is at the back.

Cut stopped at the front

It’s better to stop short. You’ll chisel the end of the dado square later, so it’s OK to stop before hitting the layout line. Over-shooting it a little isn’t the end of the world either, but make sure not to go so far that the dado extends beyond the front edge of the shelf.

From Fine Woodworking #285

Comments

Hmmm... I too like double stick tape. I wonder how well double stick tape would hold on a waxed table saw surface though.

Mike,

Nice technique,

Do you have a video on your push sticks?

Clever. If your tablesaw has "T Slots" in it's top it's easy, quick and adjustable to make your stop with a tab nut, piece of all thread and a star knob through your stop block.

Great; thanks.

Mike, wouldn't the technique would work equally well on a router table?

Would doing the stopped dadoes on the router table be as good a solution? For me, it seems as if the setup would be just as easy, possibly easier, and the result the same.

When i seen the way you did a stop for your table saw sled, what instantly came to mind was used a mag locking magnet and you can clamp or screw a aux board to the backside of your table saw sled. This would use less 2 sided tape and you wouldn't have to rely on an outfeed table. But it only works on cast iron tablesaws. But you can still clamp a long board to both infeed and outfield sides on a table saw thats not iron then with t track set up a start stop

Point. Or lock in somthing into the miter slot. Always more then one way to skin a cat. The magnets faster then tape. Cool idea never thought of it.

Surly if you do not have a magnet hold down for a feathor board you might have one for a dile indicator. They are ez to make as well with some rear earth magnets.

I know we have to work to our own level of comfort, but my goodness this technique just gives me the heebs and makes me squirm. More power to those who can muster the courage to do this, but I think I'll stick with my router table for these kinds of cuts.

Log in or create an account to post a comment.

Sign up Log in