A Table Saw Sled for Mitered Boxes

Known for efficiency in his work, Mike Pekovich has built a few iterations of his sled for making mitered boxes. In this video, he shows the progression of sleds he built, and unveils the final version. Or is it?

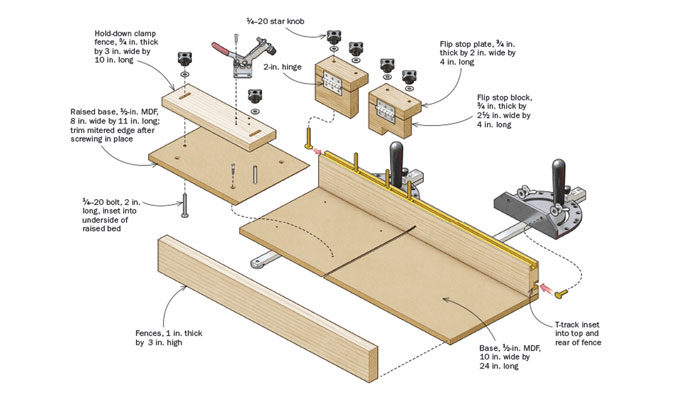

A mitered box is a simple thing to make, yet a lot can go wrong if you don’t take the time to set up properly. I’ve fine-tuned my approach over years of teaching, and I have an efficient and accurate way to go about it. At the heart is my miter sled. It secures the stock safely and has a pair of stops that allow me to cut all four sides of a rectangular box without changing the setup. Building it required just a handful of inexpensive hardware.

The sled doesn’t have to be very deep, but it should be wide enough to support the stock through the cut. I bolt the miter gauges to a T-track in the back of the fence instead of screwing them in place, which allows me to slide the fence sideways for a fresh zero-clearance cut after the kerf has been widened with use. This helps minimize chipout when mitering the box parts. There’s also a T-track along the top of the fence that makes adjusting the stops easy. To mount the T-track, run continuous grooves along the top edge and back of the fence. Inset a full-length piece of T-track on the top, but on the back use a pair of shorter tracks, staying clear of the blade area.

An important feature of the sled is its split-level base: I screw a piece of MDF to one side of the base to elevate it above the other. This allows the offcut to drop away from the blade when cutting a miter instead of being trapped beneath it. My saw tilts left, so I mount the piece of MDF to the right of the blade.

Once the sled is mounted to the miter gauges, tilt the blade to 45°, raise it slightly above the base, and make a cut. Next mount the raised base, which should be sized to cover half the sled base and extend slightly beyond the kerf. Before screwing it in place, drill holes for the bolts that secure the clamping fence, counterboring them on the underside to recess the bolt heads. Next raise the blade to trim the raised base flush with the kerf.

Each of the stop blocks consists of two blocks of wood that are hinged together. The top piece is drilled for bolts that mount to the T-track. The swinging portion of the stop is beveled on the bottom inside corner to allow clearance when lifting it.

I add a hold-down clamp to secure the parts and keep fingers away from the blade. The clamp is screwed to the adjustable fence that is bolted to the raised base through slotted holes. This lets the sled accept stock of varying widths. To set the fence, slide the fence snug to the workpiece and tighten the star knobs.

To make a mitered box, start with a length of stock that can yield all four sides. Lift both stops and slide the stock in place with one end just past the kerf in the fence. Snug up the clamp fence, tighten the hold down, and miter the end. Rotate the stock, lifting the near stop to allow the newly cut miter to contact the far stop, and make a cut. Rotate the offcut stock, trim a clean miter on the end and repeat, alternating between the near and far stops.

Comments

Why is the offcut side lower than the other? Why not just one level surface like a crosscut sled?

He explains in the video that the waste side drops down and away from the saw blade to assure no contact occurs when bringing the sled back after the cut.

Love the sled. Hadn't thought of a t track for the miter gauges. Could you please give me a name or source for the 2 miter gauges. They are a little different than most I see online. Really like the thin backs for attaching things

amazon has them, so does peachtree. search fulton

“[Deleted]”

Great sled, looking forward to adding it to my shop. Thanks Mike and FWW for the production of this.

Very nice, Mike. I like the idea of clamping the piece with the adjustable stop parallel to the fence.

Great sled. Can it be done with hardwood runners instead of double miter gauges?

It looks as though he uses dual miter gauges so he can take the sled to different table saws. If you're only using it on your own saw, I don't see why you couldn't just use hardwood miter gauge slots.

Runners would be your choice, but I like the idea that both of your hands are on the handles of the miter gauges and not anywhere around the blade area. Note that he does not have a “box” on the back like many sleds.

The miter gauges run about $55 each and can be used for other projects when the sled is not in use. They would also make it easy to adjust the back fence to ensure a “perfect” cut.

I am adapting a sled for making boxes in process to have everything except the dual miter gauges.

Mike nails it once again with this sled, great job.

PowerTec mitre gauges (Amazon) work perfectly with PowerTec track. This dual-mitre gauge idea is brilliant! This mitre gauge fits both my Bosch Contractor saw (photo) as well as my SawStop.

Don’t forget too that the dual miter guage/t-nut/track approach allows the entire sled to be re-indexed so that you can get a fresh zero cut line. Mike mentions this as one of the benefits and he is absolutely correct. I am planning to make this jig.

Was this sled written up in FWW? If so, What issue?? Thanks, Dan.

2020/2021 Tools & Shop edition. https://www.finewoodworking.com/issue/2020/10/286-tools-shops-2021

Great video as usual but I really want one of those aprons! Where do you get them?

Thanks, Mike, for a great video and article. I had made a sled like he showed in his first iteration, and had the same issue; the cutoff waste falling too close to the blade.

I have only one table saw, so I will remake my sled with two runners, but without the need for adjustment. Great idea, much safer and quicker!

Thanks for showing the evolution of your idea. I think that really helps understand not just the "how" but also the "why."

I built this jig with minor alterations. I made it 2" longer to accommodate slightly longer box sides as I sometimes make boxes up to 10" wide. I used some leftover 5/4 oak for the fences to have a bit more beef after the dado was plowed for the t-track and compensated by making the base a bit wider. I found this set of 10-Powertec knobs and t-bolts which I used throughout along with Powertec t-track:

https://www.amazon.com/dp/B0824GBM7J?psc=1&ref=ppx_yo2_dt_b_product_details

A great jig and I have always found myself being as impressed with the jigs that creative woodworkers come up with as the finished work they accomplish with them! Thanks.

As always, a great presentation. Now, a question. It appears that what you were using doesn't have strongly pronounced grain. But, if you had something with strong grain lines, when you did the cut to re-establish the correct angle, wouldn't it be better to align the end with the right side of the kerf, from your point of view, so there was as little loss of grain as possible? I hope I was clear there. :-)

Very effective jig, but you'd have to make a lot of boxes to justify the work and cost of making it.

I don't think it's that expensive. There's not that much wood. The 2 miter gauges are the more costly parts and they can be used on other jigs when not in use on this one. Shop around for the clamp.

Log in or create an account to post a comment.

Sign up Log in