Jointer Push Pads that Don’t Slip

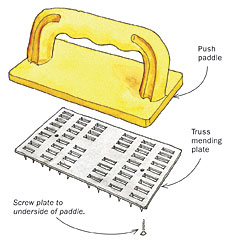

Truss mending plates add bite to jointer push pads.

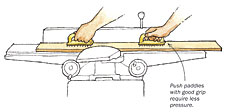

I have long been frustrated with the lack of grip from my rubber-bottomed jointer push paddles. They work well at first, but quickly get dusty and lose the friction necessary to push the workpiece across the jointer. When face-jointing, you wind up pushing down so hard you flatten a bowed workpiece as it is jointed and, after the cut, the board springs back into a bowed shape again.

To solve this problem, I screwed truss mending plates to my jointer paddle handles. These spiked plates easily grip rough lumber for quick, precise milling. Since you don’t have to push down so hard on the workpiece, even bowed boards come out straight and true. The truss plates are available at building centers everywhere, and cost only about a dollar each. The small dimples left behind are easily removed when the stock is planed to final thickness.

Willie Sandry, Camas, WA

For more on jointers from FineWoodworking.com

- Machine Setup: Adjusting Jointer Tables

- Machine Setup: Setting Jointer Knives

- How to Tune Up Any Jointer

Fine Woodworking Recommended Products

Double Sided Tape

Hedgehog featherboards

MicroJig Matchfit dovetail clamps

Log in or create an account to post a comment.

Sign up Log in