The 3 Table Saw Blades You Need

Combine one basic blade with two others and your tablesaw work will become much easier.

I want to share the three tablesaw blades I use most. Over the years I have use many types of sawblades, looking for the one that does it all. I’ve found that there is no one blade that does it all, but one comes close. Combine that one with two others and cutting most materials with a tablesaw becomes much easier. Keep in mind that this list is based around a 10-in. blade diameter. If your saw uses a different size you will need to adjust, but the principles will remain the same.

#1 – A good blade for cutting plywood – 80-tooth HATB

Let’s start with the least important. We all cut plywood now and then, some of us more than others. Cutting plywood on a traditional cabinet saw is best done with an 80-tooth HATB (high alternate top bevel). This is similar to the traditional ATB (alternate top bevel), but the angles are steeper. This makes for a more delicate blade susceptible to damage and dulling, but it makes for very clean cuts in plywood. Also note that the hook angle should be near zero or even negative. This creates a more gentle exit wound as the blade comes through the cut.

Pro tip: For better results on both the top and bottom of a cut through plywood, make a skim cut, say 1/32 in. deep, on the bottom first. This severs the fibers on the bottom gently and helps eliminate tearout.

#2 – Glue-line rip blade – 24-tooth TCG

Next up is a 24-tooth ripping blade. This is a great blade to have around for those times when you have lots of lumber or thicker lumber to cut along its length. Fewer teeth mean less heat and deeper gullets for maximum chip evacuation. This is perfect for ripcuts. For the most part these come in two grinds, flat-top (FT) or triple-chip grind (TCG). TCG are often called glue line rip blades. Both work great at their intended use of making cuts in wood with the grain, also known as a ripping cut. Having a flat-top grind in your shop can be useful. The flat-top can be advantageous in certain situations especially when cutting joinery. The triple-chip grind will stay sharp a little longer, though this is a very small point unless you are ripping miles of lumber. I also look for a blade with a steep hook angle. A steeper hook angle reduces the pressure required to feed wood into the blade.

|

|

#3 – The old standby – 40-tooth ATB

The last blade on this list, and the most useful, is a 40-tooth ATB. If I could have only one blade it would be this one. It can rip wood fairly well, especially if it’s not too thick. It can crosscut well enough, and in a pinch it will do a pretty good job with plywood. Though great at nothing, this blade does most things well enough to where 80% of the time, this is the blade in my saw. When shopping for one of these, look for one with specs right in the middle. Not too much hook, and a mild angle on the ATB.

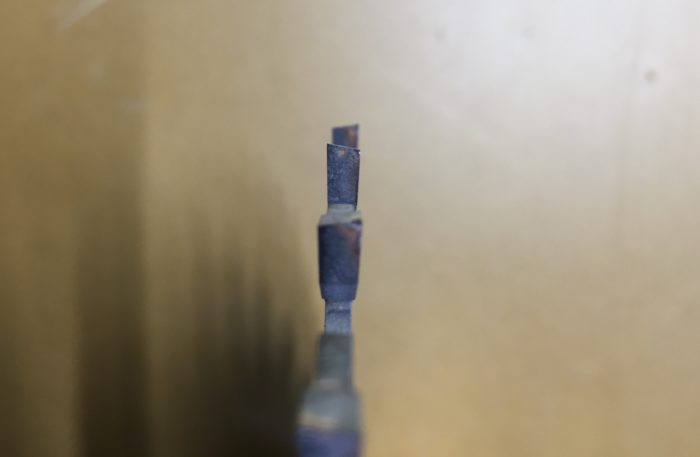

#4 – Get groovy – 1/4-in. groover

For a little extra credit, a fourth blade to keep in the shop is a 1/4-in. groover. There are a few companies that makes these. I find them very useful for running grooves for drawer bottoms or tongue and groove. I often use this blade for making Shaker doors.

As to what brand is best, I think there are a lot of great blade manufacturers on the market and I could write another entire blog post about the merits of each company. I suggest, before investing in a nice sawblade or two, think about how you are going to have the blade sharpened. Sawblades are only useful if they are sharp, and having a blade sharpened shouldn’t be an afterthought. You should actively think about it during your purchase. Some companies have great programs where you can mail your blades to them, they make repairs, sharpen, and mail it back to you. This is great, but there will be some turn-around time, so consider how long you can go without a blade. Do you need a second blade for use while the other is being sharpened?

Any reasonably sized town will have a blade sharpener or two. Typically, these are fairly small shops and are not the easiest to find. You may need to dig a little. Most of these businesses sell blades, and if you are going to use a local company I suggest purchasing the blades they sell. This way, they will know exactly how to successfully sharpen those blades. If, instead, you bring in a blade with a grind they have not sharpened before, they may struggle to get it as sharp as it was when you first took it out of the box. These shops will have a pretty quick turn-around, say two to four days. As a side benefit, many of them can do custom work. I have had a few router bits, shaper cutters, and molding knives made at my local sharpener. I also know that my man crush Mike Pekovich, as well as others, uses a tablesaw blade with the teeth ground to 7° to cut dovetails at the tablesaw. This custom grind could easily be done by a competent sharpening company.

Thank you for reading, until next time…

|

|

|

Tool Test: Tablesaw Combination BladesWe test nine blades from Amana, CMT, Delta, Forrest, Freud, Infinity, Ridge, SawStop, and Tenryu |

|

Fine Woodworking Recommended Products

Veritas Precision Square

Starrett 12-in. combination square

3M Blue Tape

Comments

It would be good to clean the blades before taking pictures, at least there used.

You can get by with a single 60th combination blade for 90% of your table saw needs with the caveat that some hand tool work will be needed on the joinery cuts.

That said you really need 4 blades and a dado stack to get the most from your table saw.

60 tooth combo thin kerf is the best all-purpose blade.

An 80 tooth blade for plywood, a 24 tooth ripping blade, and a flat bottom grind blade complete the set.

The 40 tooth ATB is a common blade in general carpentry. Sadly, we are often at the mercy of our companies to supply blades. Similarly, I have been chastised for taking time to maintain the company’s tools. You would be appalled to see the stacks of dull blades sitting in storage, only to be thrown out one day. Local sharpening shops could get our blades cutting again and keep a few more people employed.

Damage to our tools and supplies are inevitable, but would it not be better to service and maintain them before they become garbage?

I long for the day in which I own and operate a personal shop.

I've gotten by for years with a Forrest Woodworker 2 Combo blade, the Forrest Duraline for veneered plywood and a Freud Dado stack. Throw in the Forrest Chopmaster for the sliding miter saw and a Forrest WW2 with flat-top grind for tenons and that's all I've needed with the WoodWorker 2 combo in for 80% of the time at least.

Log in or create an account to post a comment.

Sign up Log in