Table Saw Blades for Joinery

Cut joinery faster and cleaner with a set of four blades.

Synopsis: Take tablesawn joinery to the next step with this set of four specialty blades—8-in. stacked dado set, box-joint set, specially ground flat-top rip blade, and specially ground dovetail blade. Because they are designed for specific functions, these blades increase your speed and accuracy whether you are cutting rabbets and dadoes or box joints and dovetails. Woodworking teacher Bob Van Dyke walks you through these blades step by step, with tips on choosing the right blade for each specific joint and using it efficiently.

The tablesaw is one of the most useful power tools in a woodworking shop, perfect for ripping, crosscutting, and a variety of joinery tasks. I keep a high-quality 50-tooth combination blade in my tablesaw 90% of the time, which I use for most ripping and crosscutting operations. But when it comes to joinery, blades that are designed for specific operations usually do a better job because they increase your speed and accuracy. From basic rabbets and dadoes to finicky box joints and fine-fitting dovetails, a set of four blades makes many joints quickly and precisely.

The dedicated joinery blades I use most frequently are an 8-in. stacked dado set, a box-joint set, a specially ground flat-top rip blade, and a blade specially ground to cut dovetails. By the way, always invest in high-quality blades; I find they far outperform most cheap blades.

Here I’ll show you how to take advantage of these specialty blades to increase the speed and precision of your machine-cut furniture joints.

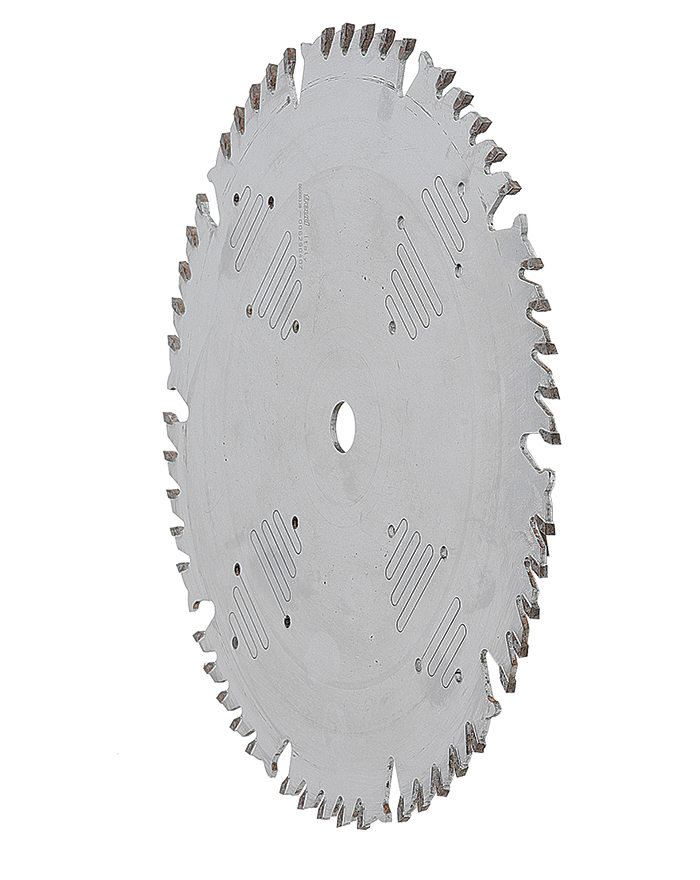

Dado set

Many people already own an 8-in. stacked dado blade set. It’s the most versatile joinery blade, making jobs such as cutting tenons, rabbets, dadoes and grooves simple and straightforward. You change the width of a cut by stacking different combinations of blades and shims.

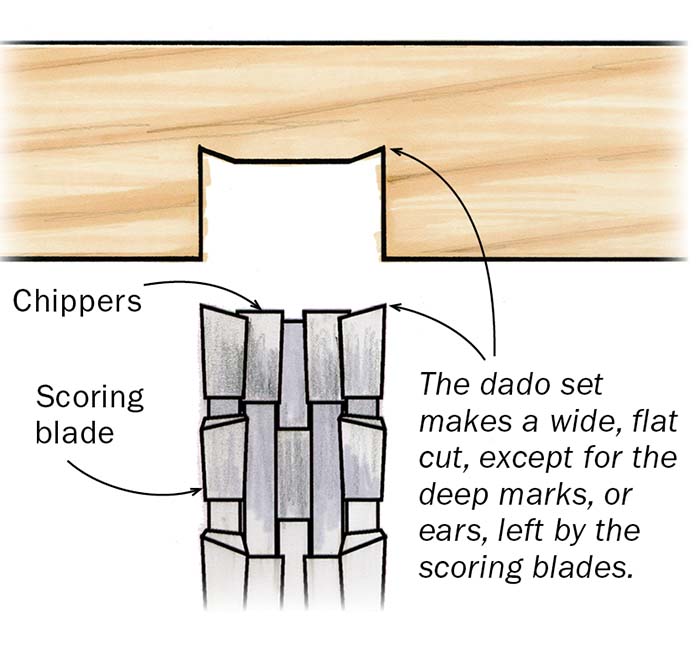

To cut a groove or a dado, simply load the number of blades and shims needed to make a specific width, and use the rip fence or miter gauge to make the cut. Make sure the scoring blades are on either end, with the high point of the angled teeth on the outside.

To cut a rabbet, use a sacrificial fence and bury the blade in it. The width and height of the exposed section of the blade determines the rabbet size. After dialing in the cut, run the board against the fence to create the rabbet.

Cutting tenons is quick and straightforward with this blade. With the dado set sized narrower than the tenon’s length, use an accurate miter gauge or a push block to guide the workpiece and use the rip fence as a stop to set the length of the tenon. The narrower dado set doesn’t have to be buried in the fence, and the smaller cuts are more accurate. While this is a very direct method and I use it frequently, inconsistencies in tenon thickness are common. The easiest way around this is to set the saw to cut the tenon just a little fat and then fit each one with a shoulder plane.

Box-joint set

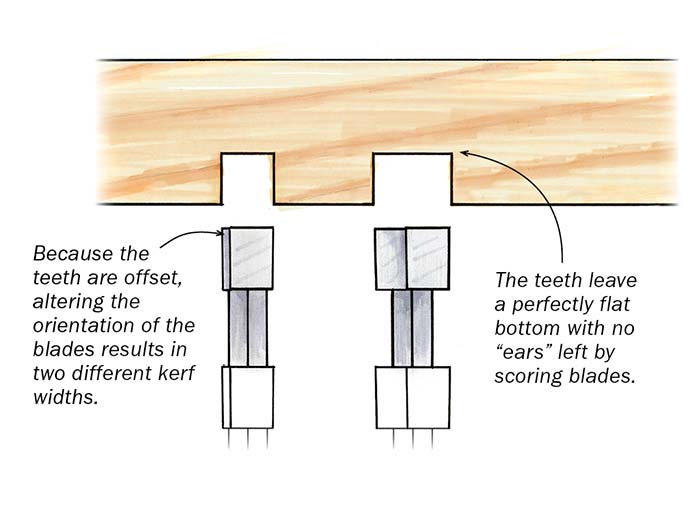

A box-joint blade set is similar to the dado set but has just two blades. It’s used for cutting box joints, also known as finger joints. The blades have offset teeth so that when they are stacked interlocking, they cut a narrower kerf and when their order is reversed on the arbor, the cut is wider. Box-joint sets are designed to cut a perfectly flat bottom, so the joint fits together with no gaps visible along the baseline.

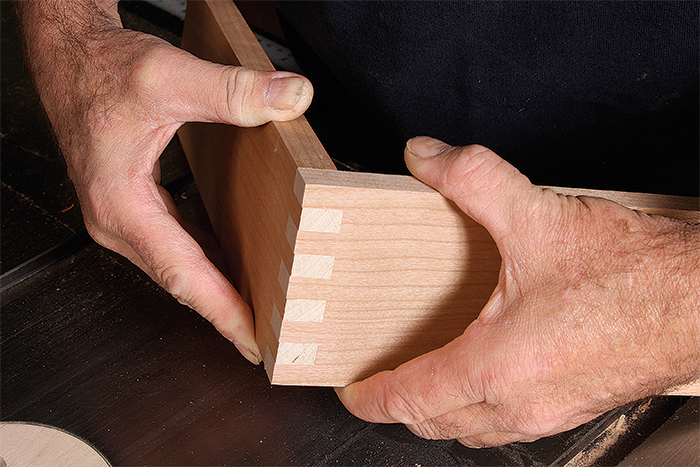

To cut box joints you must hold the stock vertically in a dedicated jig, where an indexing pin sized to the exact width of the kerf registers how much the stock is moved to create the fingers. The position of the pin controls the fit of the joint.

I rarely make box joints, but the box-joint set is great for other joinery applications as well. If the bottom of a groove or dado is exposed, the flat surface of this blade allows through-dadoes and grooves to fit the mating portions of the joint perfectly.

Also, in cases where joinery is visible, such as through-tenons and bridle joints, the grooves left by the scoring teeth of a dado blade will noticeably affect the appearance of the joint. In these cases, I use a box-joint blade to get tenons that are perfectly flat and fit into the mortise with no gaps.

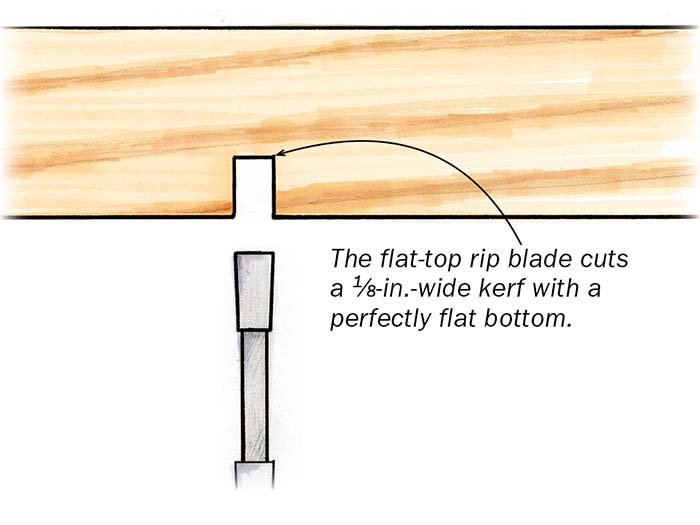

Flat-top rip blade

A specially ground flat-top rip blade leaves a perfectly flat-bottomed kerf. Most easily found in a 1⁄8-in. kerf size, this blade is useful when cutting narrow exposed grooves, dadoes, or rabbets, such as for fitting dividers or a bottom in a small box or cabinet.

It’s an excellent choice for cutting splines in the corner of a miter joint, where the flat-bottomed kerf can form a crisp line with the spline being inserted. Here the miter joint is typically held in a fixture, which is then passed over the blade.

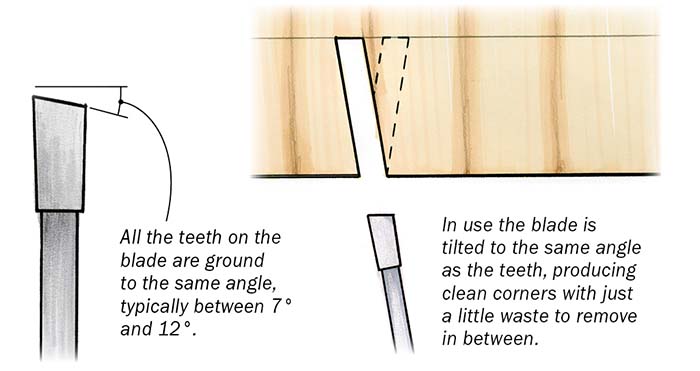

Dovetail blade

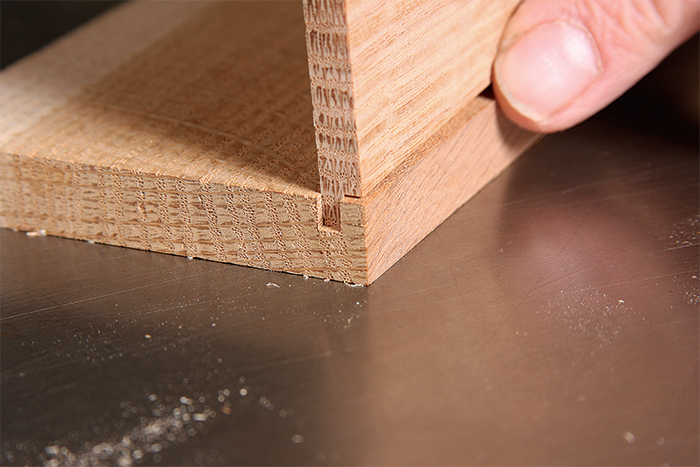

A dovetail blade makes cutting dovetails on the tablesaw almost a no-brainer. Almost any blade can be reground by a good saw-sharpening service so that all the teeth are at a consistent angle, usually 7° to 12°. The tails are cut on the tablesaw with the blade tilted to match the slope of the dovetail and angled teeth. The pins are cut by hand. Because you are just cutting to a line, you can use any spacing, including asymmetrical. While you can use any blade to cut dovetails, this specially ground blade gives better results because the angled blade cuts right up to the baseline and leaves a flat, clean surface all the way into the corner with little to no cleanup required.

To use it, I set the angle of the blade to 10° and raise the blade until it just touches the baseline. If I have set the blade correctly, the top of each cut is smooth and exactly parallel to the baseline and there’s very little paring to do. The real advantage of this system, aside from speed, is that each of the tails will come out dead straight and exactly square to the face of the board, which is critical before you can transfer the tails to the pinboard.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Rockler Dust Right 650 CFM

Veritas Precision Square

Freud Super Dado Saw Blade Set 8" x 5/8" Bore

Log in or create an account to post a comment.

Sign up Log in