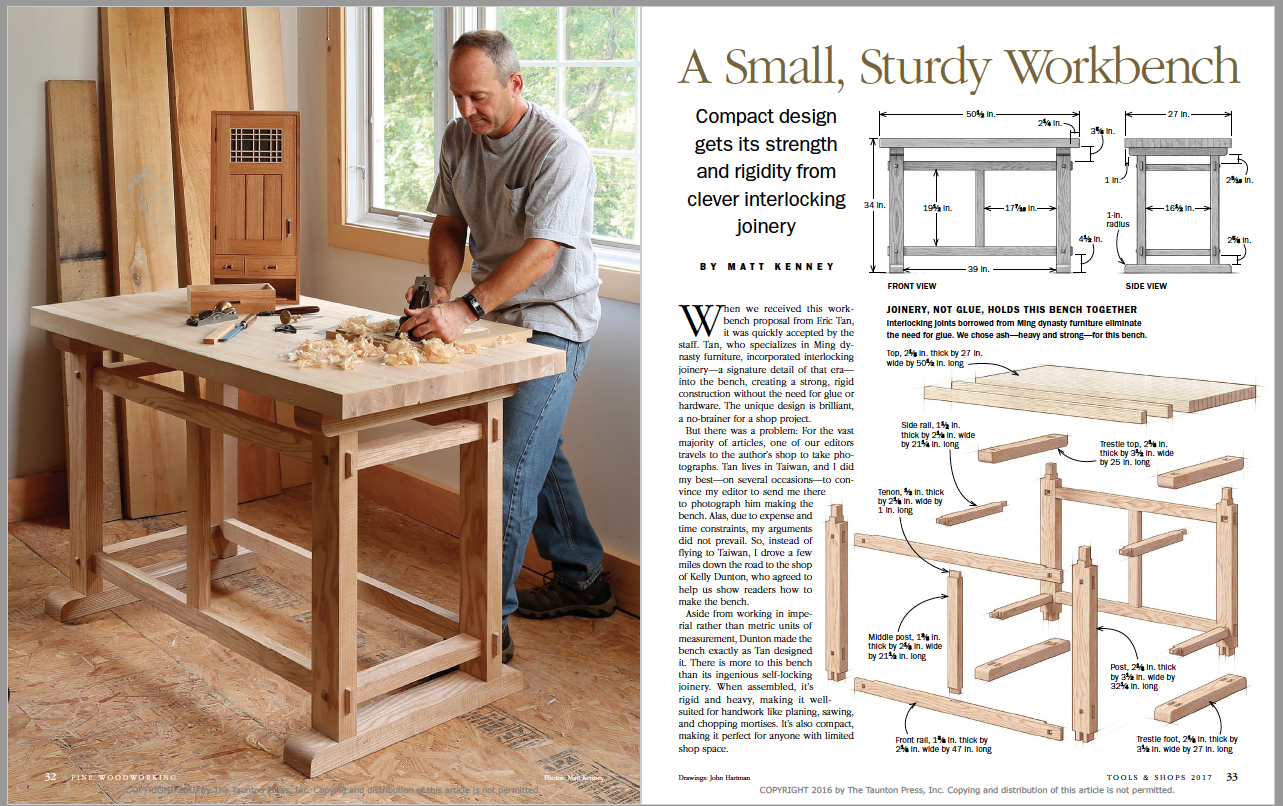

A Small, Sturdy Workbench

Compact design gets its strength and rigidity from clever interlocking joinery.

Synopsis: This workbench design by Eric Tan, who specializes in Ming dynasty furniture, incorporates interlocking joinery to create strong, rigid construction without the need for glue or hardware. There are 28 mortises in the bench, ranging from very simple to fairly complex. The bench is heavy, so it works well for handwork like planing, sawing, and chopping. It’s also compact, making it perfect for woodworkers with limited space.

When we received this workbench proposal from Eric Tan, it was quickly accepted by the staff. Tan, who specializes in Ming dynasty furniture, incorporated interlocking joinery—a signature detail of that era— into the bench, creating a strong, rigid construction without the need for glue or hardware. The unique design is brilliant, a no-brainer for a shop project.

But there was a problem: For the vast majority of articles, one of our editors travels to the author’s shop to take photographs. Tan lives in Taiwan, and I did my best—on several occasions—to convince my editor to send me there to photograph him making the bench. Alas, due to expense and time constraints, my arguments did not prevail. So, instead of flying to Taiwan, I drove a few miles down the road to the shop of Kelly Dunton, who agreed to help us show readers how to make the bench.

Aside from working in imperial rather than metric units of measurement, Dunton made the bench exactly as Tan designed it. There is more to this bench than its ingenious self-locking joinery. When assembled, it’s rigid and heavy, making it well-suited for handwork like planing, sawing, and chopping mortises. It’s also compact, making it perfect for anyone with limited shop space.

A dizzying bunch of mortises

All the joinery was done with a hollow-chisel mortiser and tablesaw. This bench has 28 mortises, ranging from dead-simple to fairly complex, combining a stopped mortise with a smaller through-mortise. Fortunately, none of them are difficult to cut. After milling the parts to their final dimensions, go to work on the mortises, starting with the most straightforward: those that connect the middle post to the front and back rails. Dunton cut them in two passes with a 1⁄4-in. bit. set the mortiser’s fence to cut the inside wall first, then flip the stretcher around and cut the second wall without moving the fence.

From Fine Woodworking #258

From Fine Woodworking #258

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Festool DF 500 Q-Set Domino Joiner

Freud Super Dado Saw Blade Set 8" x 5/8" Bore

Veritas Standard Wheel Marking Gauge

Get the Plan

This workbench design by Eric Tan, who specializes in Ming dynasty furniture, incorporates interlocking joinery to create strong, rigid construction without the need for glue or hardware. There are 28 mortises in the bench, ranging from very simple to fairly complex, combining a stopped mortise and a through-mortise. The bench is heavy, so it works well for handwork like planing, sawing, and chopping. It’s also compact, making it perfect for woodworkers with limited space. Skill Level - Advanced Finished Size – 27 in. deep by 50-1/2 in. wide by 34 in. tall Designer – Eric Tan

Comments

Where do I find the materials and cut list?

Jimmied43, you can find the plans on page 32 of FW Tools & Shops Winter 2017 magazine.

Like jimmied43 said: where are the plans and cut list as indicated on page 34??

I have searched all over the Taunton and Fine Woodworking sites and all I can find is the magazine articles

user-3933013 , lclement4 , and jimmied43 ,

Sorry about this. The Taunton Store recently got overhauled and it looks like they're backed up. We've been told there should be something there at the end of the week. So hopefully a day or two.

So without the materials and cut list it will be a bit difficult to cut all the tenons, not to say the mortises. Since I intend to try this in mesquite I guess I will wait a while.

I guess they are still backed up?

Still no plans?

Plans?

Please post those plans!

The store folks are swamped with the website migration and now with the holiday sales. If it was something we (FWW) could post it'd be done.

Hopefully soon,

Ben

Is there any update on when we are likely to be able to purchase the plans and cut list?

Hi.

From reading the comments it looks like plans will be a little longer. With the risk of stepping on someones toes the article inferred that mr. Tran's original plans were in metric which is what I'd prefer anyway since I'm in Europe and beeing slightly fractionally challenged at that. Any chance of getting hold of the original measurements?

So... about those plans, still nothing?

How come plans for the display case from the most recent publication are available in 2 forms on the store but there are stil no plans for this project? I thought the issue was the store was swamped with the holiday redesign... since they've started posting new plans I thought this one would be up by now...

BenStrano?

The plans went up yesterday afternoon.

https://www.tauntonstore.com/compact-sturdy-workbench-6093.html

Found it - Thanks Ben!

Hi. I can't access the plans with the url you provided: https://www.tauntonstore.com/compact-sturdy-workbench-6093.html.

I built this from the pictures and measurements in the magazine, however I used maple - which made it a lot of work!

I highly recommend the build, however be prepared as it is hard with only hand tools.

Now I just need to find out how to put a solid vise into the thing.

Hi, I'm thinking of making this bench. I'm intrigued by the joinery as I am of Chinese decent. Im wondering how rigid and stable this bench has proven to be over time from anyone who has built it. Thanks

Hello, As a user said earlier, I'd really like to build this bench in metric (I'm in Europe and all my tools are metric). Do the plans have metric measurements, or is it possible to get hold of the original Tan metric measurements?

Thanks for your help,

Sorry, we don't have the plans available in metric. We can't share the original plans because there are always changes made, and proofing has to be done in order to make sure everything is as correct as we can make it. It should be little more than a few minutes with a good calculator to convert the plans. Or the digital download comes with a sketchup file, which should be a mouse click away from metric.

Ok, thanks for the quick reply Ben! You guys have got to get with the times, metric is the future (and has been for 200 years ;)

Jokes aside, I'm an Englishman living in France, so all my tools and wood cuts are metric. But all the information I get is from the UK and USA, so it complicates things.

True that the sketchup conversion is the best way to go. Thanks for your help

I'm with ya!

I really like the joinery and scale of this bench. It is the perfect size for my small shop. I may modify the bottom rails though by making them extend slightly into the frame to support a pair of drop in drawer units.

I also don't see that provisions were made in the top mortises for wood movement. I suspect I will make the mortises in the top a little wide to take that into account. I also plan on installing a front and maybe even some sort of end vise and bench dog holes in the top. I like the challenge of the joinery and this will be a nice project to take advantage of the bench top mortiser I just purchased used. I am still undecided as to the species of wood to use. I may use alder since it is inexpensive. Just need to find it in large enough dimensions for the pieces in the bench.

I'm in the process of building the bench and have a couple of questions. Normally I'd fine tune each tenon to its respective mortise. Since this is designed for assembly/disassembly, should I attempt to make them interchangeable for like pieces, or keep them specific and label the joints? Also, what finish do people recommend. If it's an oil, would you finish the mortises and tenons as well? By the way, I have the top done in ash - it's heavy!

Log in or create an account to post a comment.

Sign up Log in