Shopmade Winding Sticks Guarantee Accuracy

Whether you're checking for twist in a board, a glued-up assembly, or a specific joint, there's nothing like a pair of winding sticks for a simple, foolproof method.

Synopsis: Whether you’re checking for twist in a board, a glued-up assembly, or a specific joint, there’s nothing like a pair of winding sticks for a simple, foolproof method. They’re great for checking your work when milling, keeping assemblies in line, looking for twist in a tenon, making sure joinery is square, and more.

Most woodworkers quickly grasp how vital squares and straightedges are in checking their work for accuracy. Yet neither of those essential tools indicates twist, just a bit of which can throw everything off-kilter.

That’s where winding sticks come in. In essence a pair of narrow boards with parallel edges, winding sticks allow you to determine if a board, joint, or assembly is—or is not—free of twist (or wind, if you prefer to speak the old-timey way). How do they do this? Simple. Place one stick across one end of a board and the other at the opposite end and then, with one eye closed and level with the stick nearer to you, sight across the top edges of the two. If they are parallel, there is no twist. If they are not, then there’s twist that you need to address. What’s more, a single winding stick can double as a straightedge, letting you examine for cup and bow, too. From milling to assembly, winding sticks are essential for fine work.

Feeling less fancy? See how to

use MDF for your winding sticks

From milling …

Winding sticks excel when you are flattening a board’s face. Just first remove any cup, which causes the sticks to seesaw, resulting in a false reading. For the same reason, it’s important to center your winding sticks on the stock, so I knife a vertical line at the middle of each stick as a handy visual guide.

Similarly, make sure the board’s face and the bottom edge of each winding stick are clean. Just one shaving trapped between them can lead to inaccuracy.

If a board is twisted, generally the high points are on diagonally opposite corners. To bring them down, either plane on a diagonal path from one offending corner to the other or plane each corner individually. The approach I choose depends on how the grain is running and how much bow and twist there are. If the board still has some bow in it, I might hit each corner independently, feathering my strokes to avoid creating further irregularities. To treat smaller and less bowed boards, I sometimes plane from corner to corner.

… to assembly

While most discussions on the use of this simple tool begin and end with stock prep, there are plenty of other ways for twist to wind its way into your work. Essentially any surface that is supposed to be flat, no matter its size, can be twisted enough to throw everything off. winding sticks are the tool to diagnose this.

When dry-fitting most structures and again during glue-ups, I will check for twist. For example, even though a table may have legs of equal length and sit on a level surface, it can still rock and wobble because of twist. To check, place winding sticks across the table frame, from apron to apron, and sight along them. If there is a little wind, try to find the cause. Sometimes it’s uneven or excessive clamping pressure, while other times a joint might not be fully seated. If neither’s the issue, and the twist is not extreme, perhaps you can simply plane out the twist after the glue dries. If that seems unlikely, disassemble everything to evaluate each joint. To be safe, I check for wind during dry-fitting and again at glue-up.

I also use small winding sticks to check the accuracy of tenons, placing one at the end of the tenon’s cheek and the other right behind the shoulder. Essentially any surface that is supposed to be flat, no matter its size, can be twisted enough to throw everything off course. Winding sticks are the tool to diagnose this.

From Fine Woodworking #276

To view the entire article, please click the View PDF button below.

- Winding sticks pair excellent with handwork, like flattening a board by hand. To see how, click here

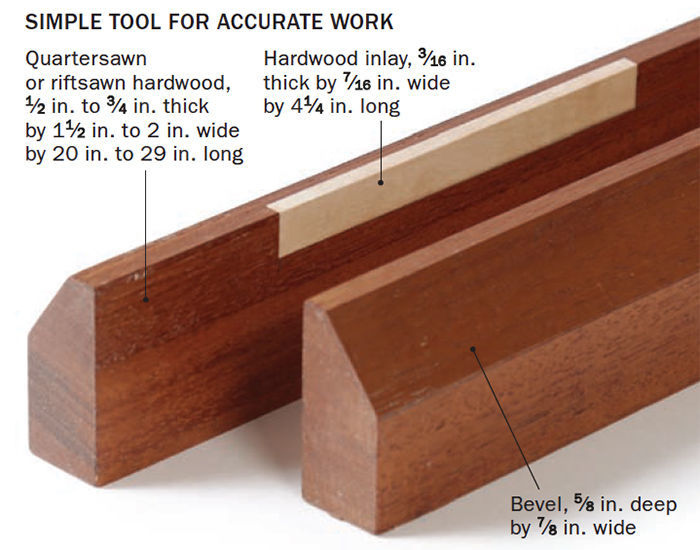

- Don’t let the inlay scare you off. A small toolkit and some patience are all you need

Fine Woodworking Recommended Products

Double Sided Tape

Lie-Nielsen No. 102 Low Angle Block Plane

Stanley Powerlock 16-ft. tape measure

Comments

This is entirely inelegant: buy a length of aluminum angle at the home store, cross cut it in half with a hack saw and, walla, you have two perfect winding sticks. Apply painters' tape on the outside of the angle. Drill holes in the ends to enable hanging the sticks from pegboard hooks. These are wonderful winding sticks. True, they are not as artful as sticks hand cut from Brazilian mahogany, but they don't warp and are inexpensive, quick, easy and entirely accurate.

Log in or create an account to post a comment.

Sign up Log in