House Your Tools in High Style

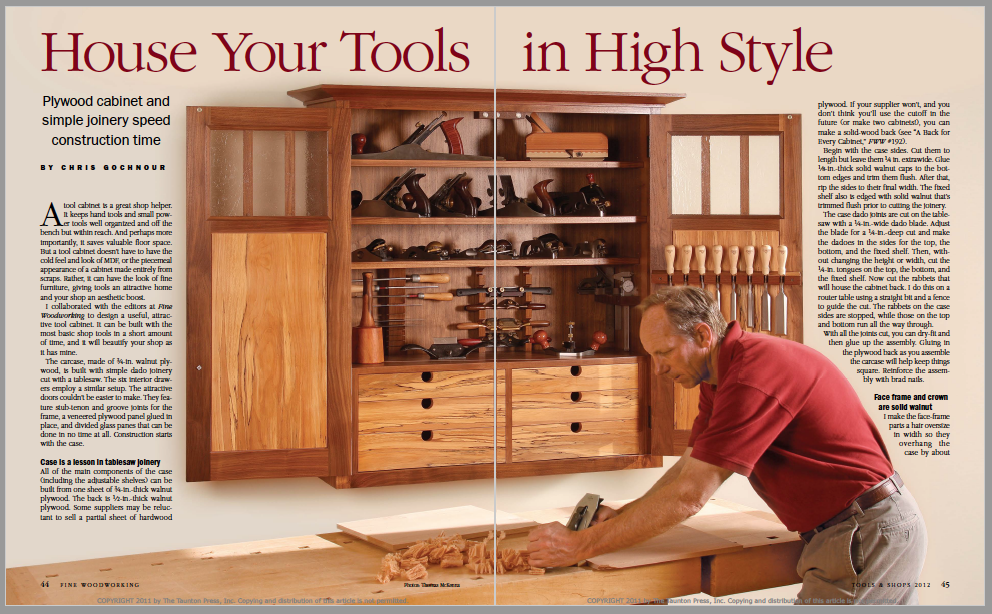

Plywood cabinet and simple joinery speed construction time without compromising the elegant look.

Synopsis: This tool cabinet blends utility and great aesthetics, giving your shop a practical place to house tools in a beautiful package. What’s more, it can be built with the most basic shop tools in a short amount of time. The carcase is simple dado joinery cut with a tablesaw. The six interior drawers employ a similar setup. The doors feature stub-tenon and groove joints for the frame, a veneered plywood panel glued in place, and divided glass panes that can be done in no time at all.

A tool cabinet is a great shop helper. It keeps hand tools and small power tools well organized and off the bench but within reach. And perhaps more importantly, it saves valuable floor space. But a tool cabinet doesn’t have to have the cold feel and look of MDF, or the piecemeal appearance of a cabinet made entirely from scraps. Rather, it can have the look of fine furniture, giving tools an attractive home and your shop an aesthetic boost.

A tool cabinet is a great shop helper. It keeps hand tools and small power tools well organized and off the bench but within reach. And perhaps more importantly, it saves valuable floor space. But a tool cabinet doesn’t have to have the cold feel and look of MDF, or the piecemeal appearance of a cabinet made entirely from scraps. Rather, it can have the look of fine furniture, giving tools an attractive home and your shop an aesthetic boost.

I collaborated with the editors at Fine Woodworking to design a useful, attractive tool cabinet. It can be built with the most basic shop tools in a short amount of time, and it will beautify your shop as it has mine.

The carcase, made of 3⁄4-in. walnut plywood, is built with simple dado joinery cut with a tablesaw. The six interior drawers employ a similar setup. The attractive doors couldn’t be easier to make. They feature stub-tenon and groove joints for the frame, a veneered plywood panel glued in place, and divided glass panes that can be done in no time at all. Construction starts with the case.

Case is a lesson in tablesaw joinery: All of the main components of the case (including the adjustable shelves) can be built from one sheet of 3⁄4-in.-thick walnut plywood. The back is 1⁄2-in.-thick walnut plywood. Some suppliers may be reluctant to sell a partial sheet of hardwood plywood. If your supplier won’t, and you don’t think you’ll use the cutoff in the future (or make two cabinets!), you can make a solid-wood back (see “A Back for Every Cabinet,” FWW #192).

Begin with the case sides. Cut them to length but leave them 1⁄4 in. extrawide. Glue 1⁄8-in.-thick solid walnut caps to the bottom edges and trim them flush. After that, rip the sides to their final width. The fixed shelf also is edged with solid walnut that’s trimmed flush prior to cutting the joinery.

From Fine Woodworking #223

For the full article, download the PDF below:

For the full article, download the PDF below:

Fine Woodworking Recommended Products

WoodRiver Router Bit Storage Case

Woodriver Rechargeable Desiccant Bag

Get the Plan

Digital plans, a cutlist, and a SketchUp drawing for this project are available in the Fine Woodworking store.

Log in or create an account to post a comment.

Sign up Log in