Make a simple, sturdy crosscut sled

Veteran woodworking instructor Marc Adams illustrates a simple approach to building a crosscut sled that will give you years of safe, accurate use.

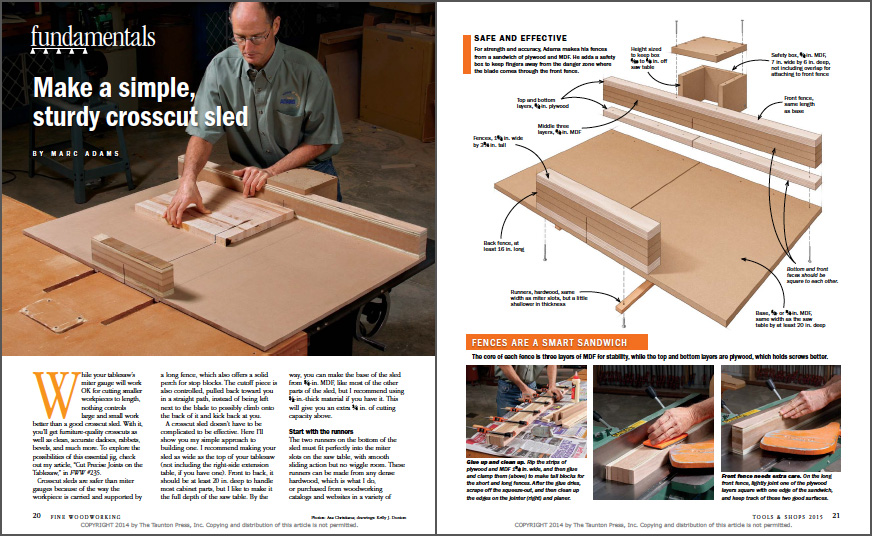

Synopsis: Nothing controls large and small work on the tablesaw better than a good crosscut sled. With it, you’ll get furniture-quality crosscuts as well as clean, accurate dadoes, rabbets, bevels, and much more. Crosscut sleds are safer than miter gauges because the workpiece is carried and supported by a long fence, which also offers a solid perch for stop blocks. The cutoff piece is also controlled, pulled back toward you in a straight path, instead of being left next to the blade to possibly climb onto the back of it and kick back at you. Here’s a simple approach to building a crosscut sled that will give you years of accurate use.

While your tablesaw’s miter gauge will work oK for cutting smaller workpieces to length, nothing controls large and small work better than a good crosscut sled. With it, you’ll get furniture-quality crosscuts as well as clean, accurate dadoes, rabbets, bevels, and much more. To explore the possibilities of this essential jig, check out my article, “Cut precise joints on the tablesaw,” in FWW #235.

Crosscut sleds are safer than miter gauges because of the way the workpiece is carried and supported by long fence, which also offers a solid perch for stop blocks. The cutoff piece is also controlled, pulled back toward you in a straight path, instead of being left next to the blade to possibly climb onto the back of it and kick back at you.

A crosscut sled doesn’t have to be complicated to be effective. here I’ll show you my simple approach to building one. I recommend making your sled as wide as the top of your tablesaw (not including the right-side extension table, if you have one). Front to back, it should be at least 20 in. deep to handle most cabinet parts, but I like to make it the full depth of the saw table. By the way, you can make the base of the sled from 3/4-in. MDF, like most of the other parts of the sled, but I recommend using 1/2-in.-thick material if you have it. This will give you an extra 1/4 in. of cutting capacity above.

Start with the runners

The two runners on the bottom of the sled must fit perfectly into the miter slots on the saw table, with smooth sliding action but no wiggle room. These runners can be made from any dense hardwood, which is what I do, or purchased from woodworking catalogs and websites in a variety of materials. Whatever you choose, check the size of your miter slots first. Most are 3/4 in. wide by about 3/8 in. deep, but some vary, especially on small, portable saws. Also, the runners should be slightly thinner than the depth of the miter slots so they don’t get hung up on debris.

From Fine Woodworking #244

To view the entire article, please click the View PDF button below.

|

Foolproof crosscut sleds |

|

Tablesaw sleds for joinery |

|

Build a Super-Precise Tablesaw Crosscut Sled |

Fine Woodworking Recommended Products

Blackwing Pencils

Rockler Deluxe Panel Clamp

Stanley Powerlock 16-ft. tape measure

Comments

Page 4 is missing??????

Looks like an ad is missing; the text continues.

Log in or create an account to post a comment.

Sign up Log in