Stack and Saw Lumber on the Same Rack

Cantilevered arms and a built-in chopsaw table provide plenty of storage, easy access, and efficient crosscutting in a small space.

Synopsis: Efficient use of shop space was a priority for this author, so he designed a combination crosscutting table and lumber rack. The framework is lag-bolted to the studs in his shop and the arms that support the lumber are tapered for both strength and maximum storage. A miter saw is mounted on a tray that slides into place, but it’s removable for installation work.

Storing lumber effectively is a challenge in any shop, but it’s especially challenging in a small shop. When I designed my current lumber rack, the efficient use of space was a priority. I wanted my lumber to be accessible and close to the chopsaw, where I cut it to rough length. Gradually, I developed the notion of a combination crosscutting table and lumber rack. While I was at it, I decided to make the chopsaw easily removable so that I could take it to installations.

Storing lumber effectively is a challenge in any shop, but it’s especially challenging in a small shop. When I designed my current lumber rack, the efficient use of space was a priority. I wanted my lumber to be accessible and close to the chopsaw, where I cut it to rough length. Gradually, I developed the notion of a combination crosscutting table and lumber rack. While I was at it, I decided to make the chopsaw easily removable so that I could take it to installations.

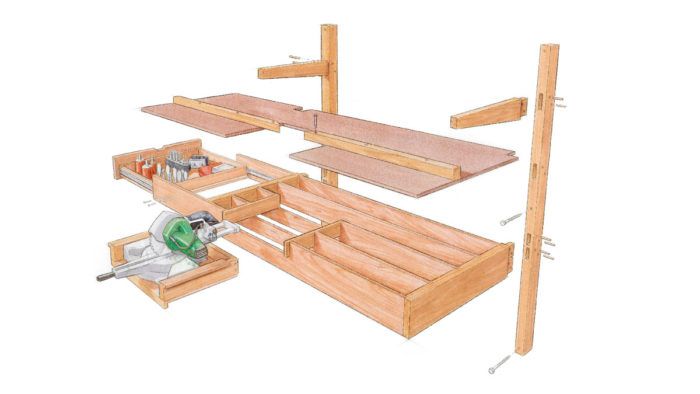

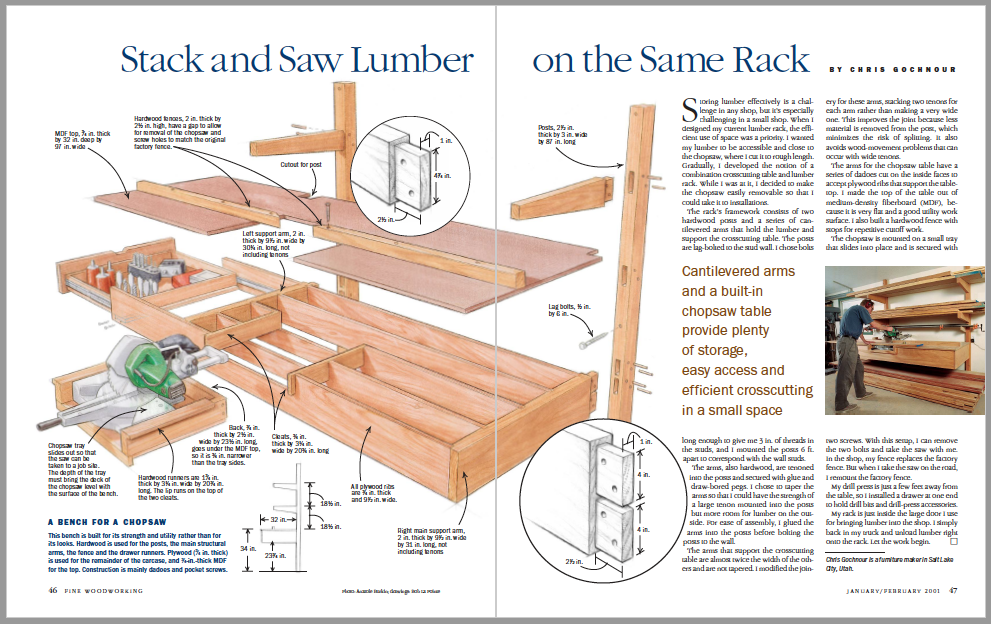

The rack’s framework consists of two hardwood posts and a series of cantilevered arms that hold the lumber and support the crosscutting table. The posts are lag-bolted to the stud wall. I chose bolts long enough to give me 3 in. of threads in the studs, and I mounted the posts 6 ft. apart to correspond with the wall studs.

The arms, also hardwood, are tenoned into the posts and secured with glue and draw-bored pegs. I chose to taper the arms so that I could have the strength of a large tenon mounted into the posts but more room for lumber on the outside. For ease of assembly, I glued the arms into the posts before bolting the posts to the wall.

The arms that support the crosscutting table are almost twice the width of the others and are not tapered. I modified the joinery for these arms, stacking two tenons for each arm rather than making a very wide one. This improves the joint because less material is removed from the post, which minimizes the risk of splitting. It also avoids wood-movement problems that can occur with wide tenons.

The arms for the chopsaw table have a series of dadoes cut on the inside faces to accept plywood ribs that support the tabletop. I made the top of the table out of medium-density fiberboard (MDF), because it is very flat and a good utility work surface. I also built a hardwood fence with stops for repetitive cutoff work.

From Fine Woodworking #147

From Fine Woodworking #147

To view the entire article, please click the View PDF button below.

Fine Woodworking Recommended Products

Woodriver Rechargeable Desiccant Bag

WoodRiver Router Bit Storage Case

Log in or create an account to post a comment.

Sign up Log in