A Fresh Take on the Trestle Table

A live edge and nontraditional joinery revamp a traditional form.

Synopsis: A simple, elegant base complements the natural beauty of the live-edge top on this trestle table. The base joinery is half laps and bridle joints, with easy angles, slight tapers, and optional pegs to add interest. A spacer between the posts creates an interesting detail without sacrificing strength. The two pieces that make up the top are joined with a spline.

As the design and production partner at New York Heartwoods, I set out to create furniture that looked elegant and handcrafted yet for business purposes had to be quick to build and simple to repeat. This trestle-style table is the perfect example. The top is a gorgeous slab of 6/4 book-matched eastern black walnut. I didn’t want to distract from the beauty of that wood, so I designed a restrained, rectilinear base that complements the natural beauty of the top. The base joinery consists of half laps and bridle joints, with slight angles and tapers, and optional pegs to add interest.

Feet And Rails Come First

Although the top is the focal point of the piece, construction starts with the base. To begin, lay out the joinery for the feet and the top cross rails. These pieces are the same length, which simplifies layout and reduces setup time. The cross rails and the feet each have two bridle joints separated by a 1⁄4-in. strip in the middle. This creates an interesting visual break between the posts without sacrificing strength and rigidity. I cut the dadoes in the top cross rails and feet at the same time using a tablesaw and a series of stops. First cut the dadoes on both sides of the cross rails and around the feet. Next, raise the dado blade and cut the deeper dadoes on the top of the feet and the bottom of the cross rails. These deeper dadoes lock in the bridle joint and create more purchase. The spacer strips on the cross rails and feet are vulnerable short-grain pieces, and are not strictly necessary. Personally, I leave the strips, but I make certain to use caution during dry-fits and glueups to avoid snapping them off.

|

|

| Cut a bridle joint on the feet and top cross rails. Using a dado set, establish one shoulder of the joint by registering on the fence (left). Then slide the piece to register on the stop, cut the other shoulder, and waste out the middle. Flip the piece end for end to cut the dado on the other side of the spacer. Repeat the process on the other face of the workpiece. Finally, raise the dado blade and cut the deeper dadoes into the top of the feet and the bottom of the cross rails (right). |

|

|

| Cut half laps on the stretcher. This piece is long and heavy, so Soto sets up a stop on a miter gauge and cuts the closest edge of the notch on one side, flips to the other face and cuts the opposite side, flips to the other end, and repeats. Then he resets the stop to cut the farthest edge of the notch and repeats. Finally, he wastes away the middle. |

Tackle The Posts And Stretcher

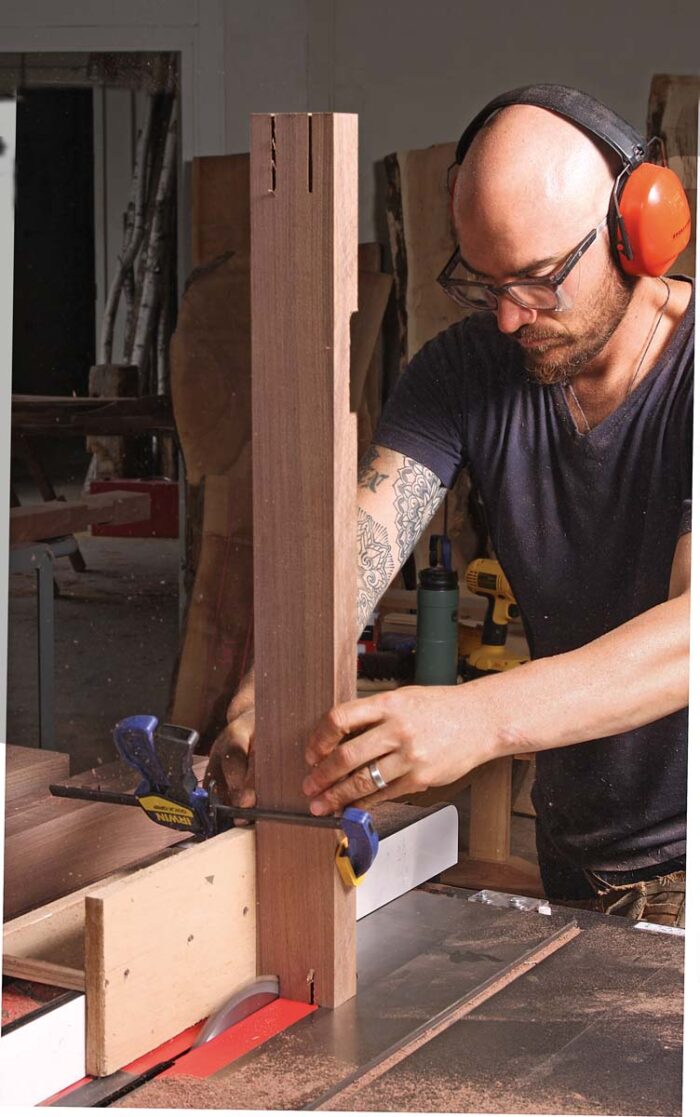

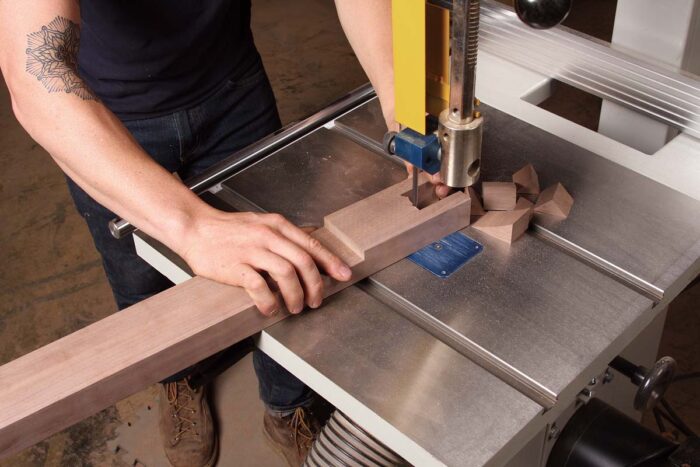

To finish the bridle joints, the two-piece posts need to be notched on the top and bottom to accept the top cross rail and foot. I cut the notch with the post upright on the tablesaw in a jig that slides on the tablesaw fence. I cut the two cheeks, cut out the waste on the bandsaw, and then finish up the flat between the cheeks at the bench. I undercut the middle slightly to ensure a tight fit.

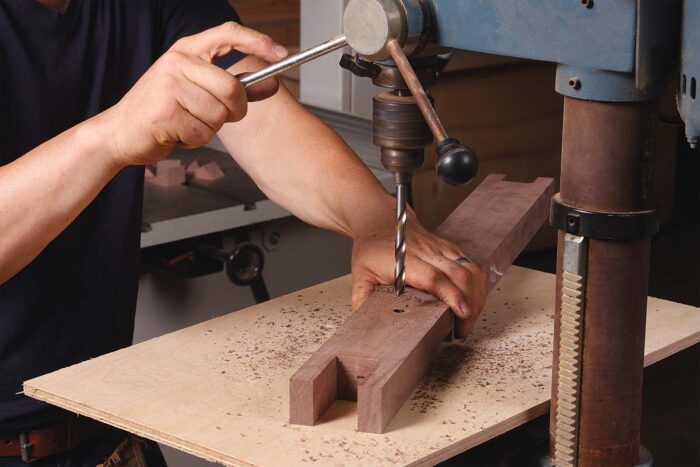

Next I cut the half-laps connecting the posts to the lower stretcher. First I cut the stretcher to length. It’s long, so I use a jig to keep the stock from tipping down. When laying out the joint, make sure you compensate for the 1⁄4-in. spacer that will separate the two halves of the posts. I use a dado set to cut the joint. Now use a 3⁄8-in.-dia. brad-point bit to drill holes for the pegs that go through the posts.

|

|

|

Tablesaw, bandsaw, chisel. Each post gets notched on the top and bottom to complete the bridle joint on the top cross rail and foot. With the post on end in a jig on the tablesaw (top left), cut the two cheeks. Then cut out the center waste on the bandsaw (top right) and finish up the flat between the cheeks at the bench (left). |

|

|

| Pegs are a design detail. Locate and drill holes in the posts (left). Dry-fit the feet, stretcher, and posts, and use a brad-point bit to mark the peg location in the stretcher (right). Disassemble and drill the stretcher. |

Time For Dry-Fitting And Fine-Tuning

Clean up and fit all the joints at the bench. After the joints are satisfactory, dry-fit all the parts. then mark for the peg holes in the stretcher with the bit you used to drill the holes in the posts.

Next, lay out the half laps joining the top stretchers to the cross rails and cross supports. Cut 15° bevels on the ends of the cross rails, the cross supports, and top stretchers. I use a chopsaw and then clean up the ends with a sanding block.

Now back to the feet. use a template to mark the tapers on the top of each foot. I cut the angles on the bandsaw and clean up the bandsaw marks with a block plane and sanding block.

you’ll want to relieve the bottoms of the feet so that there are fewer points of contact on the floor. I come in about 6 in. from each side and then stop in the middle where the post touches the floor. I relieve 3⁄16 in. from the bottom, making sure to score both sides of the foot to reduce tearout. I use stops on either end of the mitergauge fence and hog out the waste with a dado set, making sure the blade comes up to the score line. I use a backer piece to reduce tearout even further.

Drill holes through the stretcher with the 3⁄8-in. brad point bit that was used to mark the location of the pegs. Then, drill and elongate the holes for the screws to attach the top.

|

|

| Lay out the joinery for the grid. Dry-assemble the base, mark the locations for all the half laps on the intersecting pieces, and cut them on the tablesaw. |

|

Feet get tapered and relieved. Cut the taper with a bandsaw and clean up the surfaces with a plane and sanding block. Then relieve the bottoms with a dado blade and two stops on the tablesaw. |

|

|

| Angle and thin the end of the stretchers. After cutting the angle on each end of the stretcher on the miter saw, use the tablesaw to trim the block beyond the half lap. With the blade fully raised, rip in and back out (left). Snap off the thin waste (right) and clean up with a block plane. |

Sand And Glue It Up

Before assembly, I finish-sand and apply finish to the inside surfaces between the posts and to the spacers themselves, being careful to avoid getting finish on any of the joinery. For the glue-up, I like to use a slower-setting glue to allow myself a little more time and a lot less stress. Titebond III is good for this.

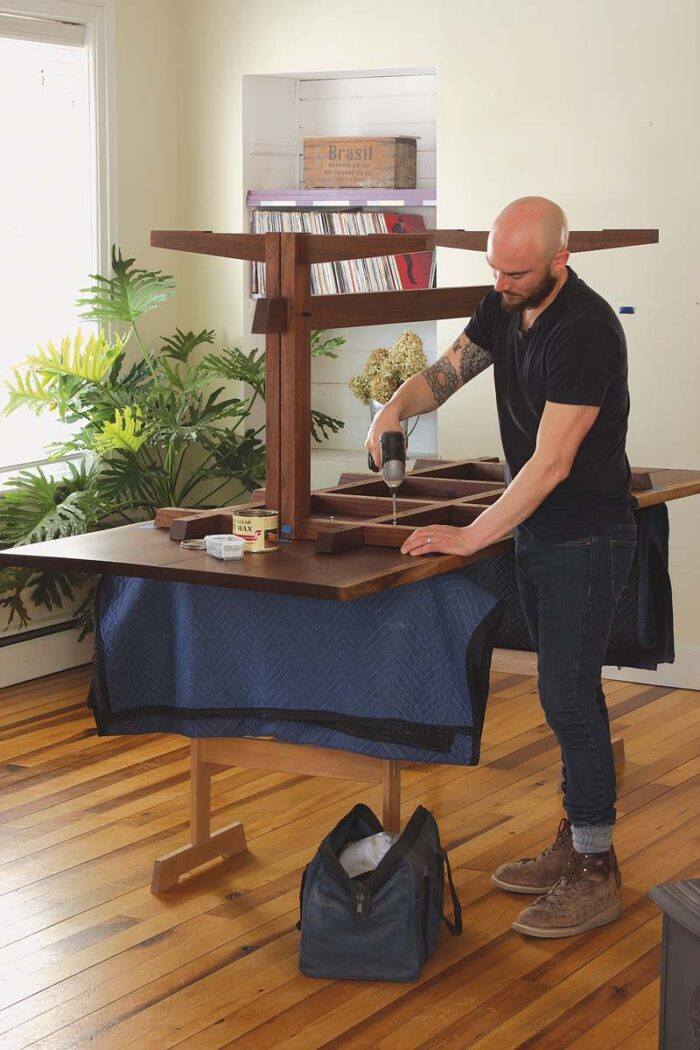

It can be a little tricky getting all the parts together at once, so a dry run is a good idea. I do not glue in the top stretchers and the cross supports. I like to leave these dry for transportation and any tricky doorways or tight corners that may have to be worked around during a delivery. I do dry-fit them during glue-up to help keep things aligned.

Last, add the four pegs that come in halfway through the leg on each side, protruding slightly. I make my own and pre-finish them. I ebonize the ends that will protrude and mask off the ends that will be glued in.

|

|

| Prefinish the inside of the posts. Because the space between the posts is so narrow, you must finish the inside of the posts and the spacers between them before assembly. | Stretcher, posts, and feet. The first step of the glue-up is to sandwich the stretcher in between the posts and add the two feet. |

|

|

| Add the top cross rails. Glue and tap the cross rails into place (left). Dry-fit the top stretchers (right) and the cross supports. These pieces help keep things aligned during the glue-up, but leave them dry so the table can be disassembled for transportation and maneuvering through tricky doorways or tight corners. |

Top It Off

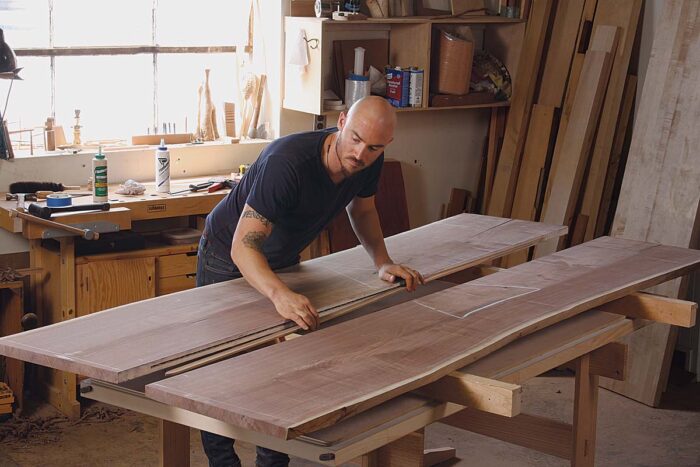

For this tabletop, I used bookmatched planks of black walnut that are about 18 in. wide. I made a router jig to flatten the top and edge-glued the two pieces together. Generally, with tabletops I like to add a spline between the two pieces for alignment and reinforcement. Alternatively, you can use Dominoes or biscuits. I also used a spring joint for the edges.

Finally, I used Osmo Polyx-Oil for the finish. I used four coats on the top and two on the base. When working with walnut, I wet-sand the first coat to fill in the grain. I find this helps with spills and overall durability.

|

|

|

Full spline between boards. Soto prefers a full spline (top left) over Dominoes or biscuits because it’s easier to align the pieces in the glue- up with a full spline. Because Soto chose boards without too much wave, he doesn’t have to use shaped cauls when clamping (top right). He does put shims into any cracks that will get butterfly keys so the clamping pressure doesn’t affect them. Screw the top to the base through elongated holes in the cross supports underneath (bottom left). |

Download the plans for this table from the Digital Plans Library. Plus, browse 100+ other plans available for members only.

Comments

Very Nice my friend.

Blows my mind why more subscribers don't comment on a job well done. We all know the time and energy that's put into a piece like this. So please tell the Man how good his work is. It's not going to kill you I promise. Lol.

I couldn't agree more with both sentiments. The work is beautiful and I, for one, appreciate the nudge to tell makers when they've done well.

festus

I love this take on the trestle table. Is there another reference that outlines the creation of the spline for the top? I have a good idea of how I would execute it, but it is always nice to see other methods.

Good question. I reached out to Marcus Soto about his splines. He cuts the groove with a router and slot cutter, and he rips the spline (a little over thickness) on the tablesaw. He takes the spline to thickness on the planer, using a sled fixed in the planer for taking thinner pieces down to size. Hope this helps. Anissa

This is an incredible piece and I'd love to have more information about the project plans. Has anybody been able to find the cutlist?

The full plans normally take a few weeks to get put on the store.

Very nice project. I note that the width of the table is 36 inches. Do you think this type of design could support a wider table; say 42 inches.

Sweet ! Like it, well thought out

Can't fine the Live-Edge Trestle table plans on site to purchase. Where are they?

They were supposed to be up some time ago, but you're right. Let me go light a fire under it.

Ok, finally! Here it is: https://www.tauntonstore.com/live-edge-trestle-table-plan

The download at least. The printed version is still going through the system. Should be the end of the month.

This is a really nice looking table, and it also looks easy to build. I'm thinking of doing a prototype in pine, using a piece of ply for the top and some 2" edging to make it look like a real top. I love prototyping furniture, although it's usually smaller scale stuff. We need a dining table though and a prototype of this would work for us while I finish other furniture projects. .

I had planned on doing the same thing once. Plywood mockup to get us by. The wife said, "just build it!".

Fantastic table! I'm going to scale one down to make a desk.

It is fun to explore new things everyday. Like this table for instance with legs that look like they belong to an antique sewing machine I used to have in the storage unit. The legs do push the focus towards the top which is very rare in furnishing these days. It is all about creativity and how you decide to portray it.

What material did you use on the table top spline?

This trestle table is so great. I'll have to give this a try; I've been looking into some automated cutting solutions and I came across this https://carveyourcreation.com/diy-smart-saw-review. Curious to know what you think about this CNC machine. Thanks again!

Great design. Impressive and beautiful. Had been looking for a base like this trestle design that leaves plenty of leg room all around table. Great addition to our home for hopefully decades to come. Thank you for making, sharing, posting.

Do not build this unless you are prepared to add quite a bit to stabilize the top looks pretty, but will not work as a dinning table. I built it for my sister.

Log in or create an account to post a comment.

Sign up Log in