Side Table with a Twist

This classic English table with drop leaves is a shape-shifter.

Synopsis: This drop-leaf table is based on an early English piece, but Chris Gochnour has given his design a distinctly American Arts and Crafts look. When the leaves are raised, the top is round. When they are lowered, the table has a space-saving, triangular top. The top pivots on a short bolt at the center of the table. To lower the leaves, just rotate the top until the leaves are parallel to the aprons. Once parallel, the leaves clear the legs and are free to drop down. To raise the leaves, lift them horizontal, and then rotate the top until the leaves are over the legs.

Cricket tables were common in England during the 18th century. Typically distinguished by round tops and three-legged bases, many cricket tables, like the one featured here, also included drop leaves, adding an extra measure of charm and utility. Although this piece is based on an early English table, I made a few changes to give it a look that’s distinctly American Arts and Crafts.

Make the diamond-shaped legs

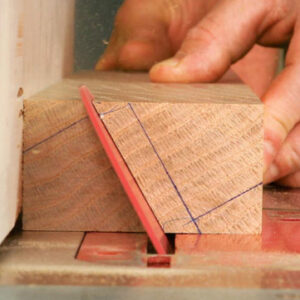

Rip blanks for the legs out of two boards, each 13⁄4 in. thick by 31⁄4 in. wide by 28 in. long. I found that using two boards simplifies the leg-making process even though it produces one more blank than needed. The extra blank comes in handy as a test piece. my sawblade tilts to the right, but the procedure is the same for a left-tilt saw as long as the fence is oriented correctly.

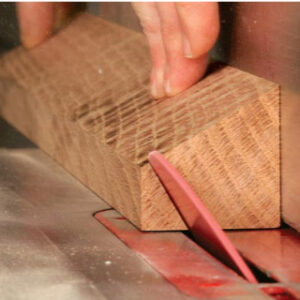

Now cut the legs to length—because the legs splay out under the table, the crosscuts must be made at an angle. begin by labeling, on a side surface, the top and bottom ends.

On both ends of each leg, draw a reference line from the 120º corner to the 60º corner. This line must always be horizontal when you trim the ends.

Now, set your miter-saw blade 7º to the left. Clamp a support cradle slightly to the left of the blade, and place the leg in cradle A with the top end at the blade and the reference line horizontal. Now, while holding the leg in place on the jig, trim the top end at 7º. Do the same for the top ends of the other two legs.

Next, shift the cradle to the right side of the blade. mark the leg’s total length at 253⁄8 in. and cut the bottom end of each leg parallel to the top end.

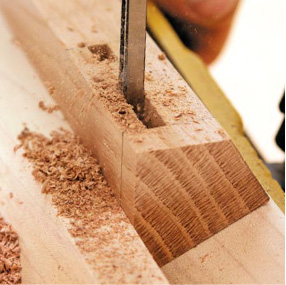

Cut the angled mortises—Each leg has four mortises—two for the aprons and two for the stretchers—all cut on the narrow sides of the legs and inset 1⁄4 in. from the wide side of the leg. With a dozen to cut, I put my hollow-chisel mortiser to work, along with the leg jig. After the machine work, I used a chisel to shave the ends of the mortises to 6º.

Tenon the aprons and stretchers

You are ready to make the three aprons and three stretchers. rip the parts to width, then use the tablesaw miter gauge set at 6º to crosscut them to length.

Cut the outside cheeks—The tenons are next, starting with the aprons. Decide which side of the parts you want on the outside of the table.

Set up the tablesaw with a 5⁄8-in.-wide dado blade raised slightly less than 1⁄4 in. above the table. position the rip fence 3⁄4 in. from the outside of the blade. Use a miter gauge, angled away from the blade at 6º, to reference the end of the apron so it’s parallel to the fence.

Then, with the outside face of the apron against the saw table and the end butting against the rip fence, cut one of the outside tenon cheeks. You’ll need two overlapping passes to remove all the waste. because the outside faces of the aprons, stretchers, and legs are flush to each other, the tenon location is important (see p. 48 for a tip). repeat on all the parts, making the cuts only on the same outside cheeks.

Now, readjust the miter gauge to angle toward the blade at 6º. make the outside cheek cut on the other end of each part. After the last cut, you’ll have all the outside tenon cheeks cut to align flush with the outsides of the legs.

Cut the inside cheeks—At this point, it’s just a matter of cutting the inside cheeks to fit snugly in the mortises. That’s done by making several cuts to “sneak up” on a perfect fit. Start by placing the inside face of an apron against the saw table and butting the end against the rip fence. Also, butt the edge of the apron against the miter gauge, which is still facing toward the blade at 6º. Then, make a shallow (about 3⁄16 in.) cut. As before, you’ll need to make two passes.

Check the tenon fit; you can expect the tenon to be too big because the dado-blade cut was shallow. raise the dado blade slightly, then recut and recheck the fit. Continue increasing the depth of cut until the tenon fits just right. Now, make inside cheek cuts on all the aprons and stretchers with the miter gauge angled to-ward the blade.

Readjust the miter gauge to angle away from the blade at 6º. Then make the inside cheek cut on the other end of each part. After the last cut, you’ll have all the cheek cuts done.

Last, lay out and mark the location of the top and bottom cheeks and shoulders. Cut to the lines with a backsaw.

Bevel the aprons and stretchers—The upper edges on all the aprons and stretchers must be beveled so they end up parallel with the tabletop and bottom shelf. Cut the bevels on the tablesaw with the blade tilted to 4º.

Now you can go ahead and smooth all of the surfaces with a handplane to remove any mill marks.

Band clamps ease assembly

Assemble the legs, aprons, and stretchers. The joints are angled and the base is triangular, but band clamps work wonderfully. You’ll need just one for the aprons and one for the stretchers. The glue-up is a five-minute operation. Use a small brush to apply glue to all the mortises and tenons. Assemble each one, and then add the band clamps.

Install the axis board—The axis board runs parallel with one apron and is notched into the other two. A slightly oversize hole through the center of the axis board accepts a machine screw that secures the top to the base and serves as a pivot point

Notch the base for the hinge barrels—When the top of the table is rotated 60º to open or close the leaves, the hinges pass over the top end of the legs and aprons. So, at each of the three corners of the base, you’ll need to cut a 1⁄8-in.-deep notch to al-low clearance for the hinge barrels.

Mark the notch locations with a trammel, then use a router to remove the waste be-tween scribe marks. Finish with a chisel.

The top is fun

The top is an interesting geometric array made up of six boards. Three are isosceles triangles joined with splines to create a central equilateral triangle. The other three are circular segments, and attach (with hinges) to the central triangle to form the drop leaves and create a full circle. From the drawing on p. 50, make a full-size template of the triangle and the drop leaf.

Use the two templates to lay out the isosceles triangles and leaves in a row on a single board. Cut all six parts on the band-saw, making sure all are slightly oversize. Then, use the tablesaw with a cutoff table and protractor fence to trim the two inside edges on each triangular piece so they’re straight and meet at exactly 120º. Later, after the sections are glued, handplane the three outer edges to exact size.

The splines keep the triangles aligned during assembly and add glue area, which means a stronger joint, important because wood movement will stress these areas. You can cut the stopped grooves on a router table with a 1⁄4-in. slot-cutter buried in the router fence. Elevate the slot-cutter so the cut will be centered on the 3⁄4-in.-thick stock. Then, set the fence to make a 3⁄8–in.-deep cut.

Note that each triangular piece has one long edge, and two shorter edges of identical length. Each of the two shorter edges gets the stopped groove for the splines. On one of the edges, you begin the groove at the stopped end by plunging the slot-cutter into the stock and then feeding the entire edge of the triangle through the cutter. When making the plunge cut, it’s important to make sure the triangle corner nearest the plunge is kept firmly against the router fence to serve as a pivot point. Don’t use the opposite corner as you’ll likely run into some kickback as the stock is plunged.

To cut the remaining edge, place it against the fence, then feed the stock into he slot-cutter. Stop the cut just short of the triangle corner before using the opposite corner as a pivot point to swing the edge away from the cutter.

To clamp the three triangles, I make a clamping table out of melamine and hard-wood braces (see p. 50). It uses a system of wedges to apply even clamp pressure to the triangles. When the glue has set, remove the excess glue with a scraper and handplane. If handplaning isn’t your forte, you can simply sand the top and bottom surfaces smooth. Complete the triangular top by planing the outer edges to their final dimensions.

With the triangular portion completed, use a trammel set to a 101⁄2-in. radius to make reference marks where the circular leaves will be attached. The points of the triangle will be trimmed later to align with the leaves.

The shelf is like the top—The triangular shelf is a thinner version of the one on top, but the construction is essentially the same. make a full-size template of the isosceles triangle from the drawing on p. 50.

Mount the leaves and attach the top

Now you can attach the drop leaves. First, use a spokeshave to smooth the curved edge of each leaf to the line traced earlier.

The hinges are 7⁄8-in. by 11⁄2-in. butt hing-es from White Chapel Ltd. (www.whitechapel-ltd.com). To mount them, mortise the hinges into the leaves at a point 3 in. from each end. With the hinges installed on the leaves, align them with the triangular top and transfer the hinge locations. Then mortise the top and screw the hinges in place. Now use a bandsaw, file, and sander to shape the points of the tabletop to align with the drop-leaf curves.

The top is fastened to the base with a machine screw that slips through a slightly oversize hole in the axis board and into a threaded brass plate mortised into the underside of the top. Drill and tap for a 1/4-20 thread in the center of the plate. Then, bore and countersink for four 1⁄8-in.-dia. holes near the corners of the plate. Cut a mortise to accept the plate, and secure it with #6 by 1⁄2-in.-long brass wood screws. Now, attach the top and enjoy this unique side table.

Get the finish recipe for the table in a companion article.

From Fine Woodworking #200

For the full article, download the PDF below:

Comments

“[Deleted]”

Log in or create an account to post a comment.

Sign up Log in