This past week I returned to my bench and mocked up a sewing table to be made from a wonderful plank of narra we picked up from our friends at Gilmers in the fall of 2006. The highly prismatic rich gold color darkens with age and is easily worked with fine edges and will work well for the marquetry planed for the top, or so I thought.

I placed the Narra on my bench carefully sliding the rather heavy plank against the far dog on my bench. I reached for a favorite plane. One of Vera, a gift from JK. The plane has lovely weight and fits my hand as good or better than any I have used. Golden shavings fall off the side of my hands as the plane glides effortlessly across the plank. The bench is creaking, so I take my small Japanese hammer from my bench and tap each of the tusk tenons at the end of the stretchers. I go back to planing and again, I feel reconnected with my work.

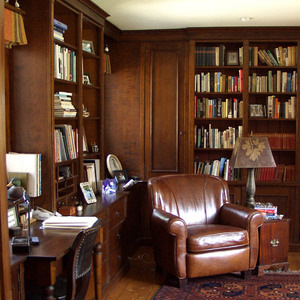

It’s holiday Monday and it is still dark when I arrive at the school a few minutes before six. I go into my cozy little benchroom and turn on my bench lights. I walk through the woodroom and open the front doors of the school in the benchroom. I grind some beans and make a coffee and turn on a few more lights. I make my way past the front bench through the machine room and unlock the back door. I walk past the wood box and pick out a few pieces and then put them back leaving them for someone else to discover. I return to my bench, turn on the radio and listen to the six o’clock news.

I pull out a few sketches of the small sewing table. I predict a few dimensions from the sketch and head out to the machine room where I saw and dowel together something that approximates what I want. I cut legs, four of them each with intention but slightly different and return to my benchroom, reach for my spokeshave and begin fairing the curve and shaping the legs. This kind of work is truly joyful work, liberating work. The poplar is mild and it doesn’t bit back if I am not paying close enough attention. I assemble the mockup, step back and look. Too heavy and the pinch is too low in the leg. I take another leg and shape, this one is more what I had hoped for and leave the other two for later on, should things change. Now the volume of the table is wrong. I dismantle again and head back to the saw with the aprons. It’s nice to have a fine saw, one that sounds smooth and is free of vibration. I take a few millimeters, then a few more. Back through the benchroom where a few of the students have arrived and are enjoying a coffee. We talk and I go back into my room and put the mockup back together. Better but it needs something. I grab an off cut of veneer and cut it to width with my favorite knife. I attach it to the bottom side of the apron, a little thinner and now it seems right.

The next morning I read a few pages from A Cabinetmakers Notebook, look over my notes and head out to the main benchroom to cut dovetails with a very eager group, and why not, I can’t think of a better way to spend a sunny and brisk fall morning. We talk about the coming elections, of coffee and the beautiful place in which we live. I ring the bell and we all gather around the front bench and talk about the lovely fall we are having and the recent bear sittings. We discuss things that they have bin working on, how those imperfections that they stressed about all weekend were not nearly as bad as when they left on Saturday. I go through the layout, not bevel gauges, but by eye. We need to start

trusting our eyes more, not because we are an “Artist” and need creative freedom, but because our eyes pick up what measuring devices cannot. Our eyes take in consideration grain, tones and subtle curves which bring our work alive. The saw cuts straight, yes but we do not fit off the saw, we just sharpened it and it cuts beautifully but the joint needs a fine chisel to carefully remove the fuzz left from the saw and mate the subtle curve we have put into the pins. We are cutting kwila and locally harvested arbutus. This kwila is a little brittle and care must be taken not to tear the fibers near our scribe line. “Don’t get greedy.” Jim would say. The arbutus is much easier to make friends with. It’s fine grain and color much like air dried pear wood . It requires lower angles on our chisels and light cuts. I finish up my attempt at making it look easy and send them off to their benches with a bit of hope. Juan Carlos and Ian are both able to cut the joints at least as well as I. have begun to realize my evolving place at the school remembering that we need not only to show our students how but why we work the way we do.

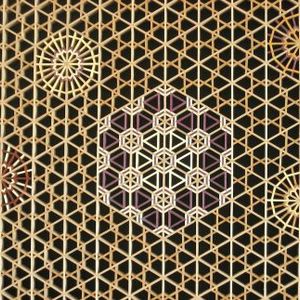

On Saturday morning I arrive at the school shortly before six. Ian’s day to teach, I will work at my bench. For the last few nights I have festered over the wood. On Thursday morning I came to the realization that the highly prismatic plank of narra from which the sewing table evolved was not going to work for the piece. The plank had been cut from the log on the diagonal making it impossible to get the grain graphics the way I wanted. In the mean time I pulled out a plank of kwila that I have had with me for eight years and began to plane the surface. The chocolate brown sheared surfaces glimmer with silica which I know will require frequent sharpening but the wood works easily. As I cleanup the plank I discover some interesting figure inconsistently throughout the plank. Another disappointment. How can I possibly get what I need from this piece with consistent figure. I tell my students that they need to be prepared to have the wood shape the piece, even after mockups are complete. Let the wood speak, and do our best to listen. While the kwila does not have the highly prismatic properties of the narra the marquetry I had intended to use is not likely to work. The inconsistency of the figure makes it difficult to get graphics with any symmetry. I make a few sketches and look at the mockup again. This time imagining it with the figure on just two corners, draping itself over the top down the aprons, drawer fronts and the legs. I return to the machine room, plank in hand with renewed enthusiasm.

‘Letter Home’

With the kwila milled and settling in my benchroom, I turn my attention to the letter box to be made of some very sweet wood I had milled and set aside some time ago. When I unwrapped the parts there was little to no movement allowing me to avoid the machine room for a while. I spend a few minutes familiarizing myself again with the material. I reach for a favorite plane and began planing the inside surfaces of the box. The cocobolo I am using is milder than what I am used to. It is much lighter in color and weight and has wonderful figure. It takes a fine finish off the plane. The shavings have a floral fragrance. I turn my attention to squaring off the ends. I reach for my shooting board and realize that it has been neglected for some time. I am anxious to get to the joinery so tuning it up will have to wait for now. I sneak into the machine room and make a few crosscuts then quickly and head back to the tranquility of my benchroom.

The scribe feels familiar in my hand, it has been with me for many years and slices a very fine line where I have intended. I reach for an off-cut and sketch a few layouts, decide on one and proceed to layout the pins. I begin from the outside edges and work my way towards the center. I draw not straight lines with a bevel gauge, but subtle curves by eye.

My saw is still warm from cutting joinery with the students last week and cuts effortlessly somewhat close to my line. Leaving to much will mean a lot of paring and the potential for shifting. I draw a few more lines in between a couple of pins and get familiar with the wood getting progressively closer to the line until my confidence returns. My eyes are no longer as sharp as they once were, I adjust my lights, take a deep breath and cut as close as I dare to the waist side of each line. With the sawing of my pins complete, I make a coffee and spend a few minutes on my edges. I modify a few angles and test the end grain looking at the quality of cut and checking durability. The angle is what it is, perhaps an angle similar to what I would use for kwila.

I pull out my chopping block and plane the edge square to the bottom face. I clamp the block on my scribe line and adjust by tapping it lightly with my small hammer. I begin chopping the sockets, “A little down, a little in, and don’t get greedy!” Jim would say. The wood has some curl and I have to keep the cuts light or the chisel wants to dive. I remove the work piece from the chopping block and pare each set of pins square to the end. I put my tools down turn off my lights and head out for a walk.

When I arrive back at the school most of the student are already at their benches and a few are setting up machines anxiously waiting for some power. Juan Carlos taught doweling this morning and the students are busy working on the doweling exercise. I begin to make my rounds. The doweling exercise is a good warm up for many of our students who have decided on wall cabinets.

The sky was very clear on my walk in this morning. The stars were brilliant and shape of the moon reminds me that we need to spend some time with our coopering planes which we will need next week. I arrive at the school make my way through my benchroom, the woodroom and wander around looking at the previous evenings work. There are a few new joints, a few new exercises completed. The benchroom feels calm, it feels like a place where people want to be. That is important that we feel comfortable and relaxed in our work. I wander back into the machine room and have a look in the wood box finding mostly firewood.

It is times like this that I am reminded why we built this school. I look around the room and realize that people are committed to this way of working, curious enough to travel fare distances and relocating their families to join us. I am filled with a deep sense of gratitude to our students, for without them our school would simply not exist.

The students begin to arrive, we chat share a coffee and a bad joke. I head back to my little room to get some work done. I sit down at my bench and study my early morning work and discover that the spacing isn’t as bad as I remember. I reach for my paring chisel, give a quick hone and set to work paring a little flare into each of the pins. Too much it makes the fitting to the tails a little tougher, too little or inconstant and it begins to look like a miss. I enjoy this process, the chisel cuts across the brittle grain shaving a little more from the center lighting up the cut at the end to prevent blowing out the back side. As I hold the chisel completes the cut I rest its back against the side of the pin. The back of the chisel is polished and helps me judge the depth of flare. It needs a bit more so I take another pass.

The first few take a while but as my confidence improves so does the efficiency and ease of my work. My neck is getting tired, I readjust my light and decide to stand for a while.

The students have gathered on the deck for a break, I make a coffee and join them. The sun warms our spirits and the cool fall air is fresh the talk is all about the United States election. The world just seems like a better place this morning.

I return to my cozy benchroom, put away a few tools and set up for the transfer. I scribe the tail stock, keeping in mind my layout and not scribing where it is not necessary. I sharpen my pencil and carefully transfer my lines. This cocobolo is unusually light and I can see my line without having to change my lead hardness. I sit down at the end of my bench and begin sawing the tails. I rotate the work piece in the vice giving me a vertical line. I tilt my saw almost un perceptively towards the outside of the joint which will make my pin socket tighter towards the outside of the joint. It is not that I do not trust my saw or my hands but it gives my a little room for miss reading the grain during initial paring.

I clearly mark my waste before set the chopping block up. I find a few narrow chisels and realize that I am limited to just one for the chopping. I like the look of small pins but sometime it can get me in trouble. I head out to the grinder and make a few modifications to another chisel and hollow grind the iron of my block plane while I am out there. The machine room is pretty quite, just myself and a second year student. I am humbled by the complexity of his work and am grateful for the simple work I have chosen.

I return to my bench and begin to chop, making sure not to bruise the sides of the tails. The chisel has been modified to allow me to get much closer to the corners but I will need to remove the last of the crumbles with a knife, one with a modified bevel on just one side allowing me to get into the corners without diving. I will leave the fitting for the morning when I feel fresh. The sun is shining and it is time for a walk.

The next morning I am treated to lovely light streaming through the windows of my benchroom as I carefully pare to fit each of the joints. The first corner takes a while, as my confidence return so does the efficiency of my work. I dry fit the box mark outside edges and face with blue tape and return to the machine room to run the slots for my bottom panel of and for the frame and panel lid. While I am there I size the panel of portorford cedar using my story stick and run the lip for the panel on the shaper.

The students have their mockups underway as I return from my walk. We look at sketches, talk about volume, shapes and of course the wood. There are several planks on sawhorses throughout the shop and the floor is filled with fresh shavings. The smell reminds me of my little shop in the mountains years ago. There is excitement, hesitation and lots of enthusiasm, a wonderful environment for careful work.

I assembled the letter box the previous day. I reach for my favorite smoother and with the box clamped to the side of my bench I begin to take flush off the joinery. The cocobolo is rowed however with alight cuts and sharp iron the light shavings reveal a fine surface. The edges are softened carefully ensuring “kindly edges.”. The final test is by feel with my eyes gently closed. This is something I learned early on and has stayed with me. Our hands are equally as sensitive as our eyes often picking up what our eyes miss.

Ian arrives at the school with a rocking chair in walnut and leather he recently completed. We move it into the center of the gallery and he invites me to sit. It is as comfortable as it is beautiful. I am filled with a deep since of pride for this fine young craftsman and teacher.

I return to my benchroom and try some finish on an off cut. I decide on a light coat of oil with a little wax. The cocobolo is lovely untreated but over time would get dirty with frequent handling. There is something almost sensual about applying oil, the color and figure in the wood becomes alive as I rub down each surface and edge. I go out and visit with the students, share a moment with Yvonne and head back to my benchroom and remove the oil that has bled back to the surface.

The afternoon is spent discussing joinery and rebates. The progress is good. The previous week we discussed the importance of keeping procedure lists which our students are encouraged to keep. We will need to talk about the making and installation of hinges and wooden latches, which we will begin tomorrow. I prepare for tomorrow’s lecture and make a handout so they can concentrate on the demonstration instead of taking notes.

After a cup of coffee with one of my students, I return to my benchroom and mockup my frame and panel lid. I have an idea of what I want and after and a few minutes I take the material which has been resting down to final dimension and begin cutting the joinery. The graphics show an inward curve, hopefully drawing attention to the panels. I begin on the bandsaw carefully cutting the open mortises. I then cut the shoulders for the tenons on the table saw and the cheeks of the tenons on the bandsaw. The small rails require mortises, so I head over to the mortiser. Working with this machine, the way we do requires minimal setup and is a true example of workmanship of risk. This is a machine process which I enjoy very much.

I return to my bench and carefully fit the joinery. I had intended on using a very sweet of piece of narra, a gift from a former student. The grain is a fine match with the cocobolo and planes beautifully however it is a little too yellow. I search through a few planks and come across a piece of very tight grained curly Tasmanian Black wood. The plane slices through the sawn exterior surface revealing lovely brown wood with a little flash of red. I reach for my amber polish to bring out the rich warm tones in the wood. I hold it next to the box and am pleased with the combination. I cut out a negative template and find my panels, return to our fine bandsaw and saw the book matched panels, which have a subtle inward curve. I set them aside to rest and head out for my walk.

I arrive back at the school to find many of the students waiting for me to turn on the power. There is wood to cut, mockups to refine which leads us back to the wood for answers. I will put off making hinges with them until tomorrow. There are many questions to answer and lots of wood to look at with our students.

I arrive at school before six and after my morning ritual of coffee and wondering through the shop, I head into the machine room. I have the frame and today I will mill the tenons, one each of the panels. After a brief visit to the table saw for the shoulders I spend a few minutes tuning the bandsaw and then cut the cheeks. The saw is cutting so well it is hard to tell that it is a sawn surface, this enables me to get an almost fit off the saw. I return to my benchroom and after a few passes with a file I have a fine fit. A few of the students have arrived so we chat and I clean off my bench. I sharpen a few irons begin to soften the edges and prepare the surfaces of my frame and panel components. I enjoy this work, shaping is a sensitive thing. We can change the way people look at the work with transitions and steps. After a couple of hours, I am applying finish. A light coat of my oil mixture for the exterior of the frame. The panels will receive a couple light coats of amber polish then wax.

I just finished the hinge making demonstration and am reminded never to assume anything. The number bit I use for the pin hole prior to reaming was been replaced with a larger bit and my pin slips right on through my press fit hole. I tell the students I do this for demonstration purposes and we have share a laugh. The remainder of the day is spent mostly looking at wood and discussing changes with their mockups. It has been overcast for a few days but this afternoon the sun came out for a while, many of use take a break on the deck.

I arrive at the school at six thirty, I spent some time at home in front of the wood stove sketching this morning. Working is giving me ideas for new pieces and I am feeling inspired once again. I know that these pieces will have to wait as I have enough work to carry me through until the spring. I begin the assembly of the frame and panel. I do my glue ups in manageable stages, working from the inside out. While in clamps I go through the kwila, narra and kauri pine that I milled a few weeks back for my next piece, a small sewing table.

It is Saturday morning and I arrive at the school early, I couldn’t sleep last night. I remember getting like this when I am nearing the completion of a piece. Questions, Did I make the best use of the material? Will the client like it? Do I like it? The answers will have to wait. I run the lip on the panel and cleanup the edges with a file and a bit of paper and apply some wax. We are entering the dry season so fitting the lid too tight will mean a call from the client next summer so I spring the fit, planing a slight curve along its length giving it room to breath the slot yet giving it some tension so the box can be handled without having to worry about the lid sliding out unintentionally.

After several sketches and mockups I decide on a pull. I pull out a small piece of Costa Rican cocobolo from a stash of wood under my bench, a little darker than the Nicaraguan I used in for the box. I cut off a slice and mock up the pull in the real wood and it seems to work. I take my finished frame and panel into the machine room and attach a block to stabilize the cut. I hold my breath and make light passes with the sharp end mill on the mortiser leaving a clean mortise. The Cocobolo I have for the pull is not large enough for the machines so I sized it by hand back at the bench. I make a quick jig to hold my pull as I run it over the shaper to form the tenon. I head back to my room stopping by the front bench announcing to the class that I will present on Friday at the end of the day.

I pull out a few gouges, files and a small shop made scraper and a finish pull and fit the tenon. I apply some finish, make a couple of clamping cauls and clamp the pull in place.

I leave the shop early and take a walk. I am filled with a deep sense of gratitude for the new found balance in my life.

Comments

RVN & Inside Passage are the most inspiring thing to me; I would give one, maybe two of my toes from my left foot to be able to study there. They are really putting out some amazing craftsmen & women.

Regards, Jarrod

Jarrod,

Thank you for your kind words of encouragement. I do realize our way of working is not for everyone however it makes me happy that there is a place for some of us who care intimately about our craft.

Be Well,

Robert

Inside Passage School of Fine Cabinetmaking is deeply saddened to

announce the passing of my dear friend and teacher Jim Krenov.

A celebration of Jim's life and work will be held at the school in the coming weeks. We will be posting the details in a few days.

Log in or create an account to post a comment.

Sign up Log in