Bookcase and More

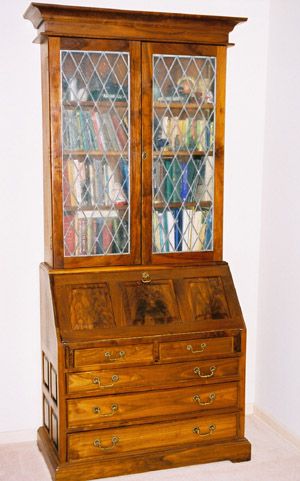

Leaded Glass Bookcase Doors with adjustable triple shelving. Crown molding and all raised panels are coved on the table saw.

Bookcase and More

Built in two sections.

The Writing Secretary has an inlayed, hand tooled leather writing surface. The letter compartments and drawers are delicate and curve outward. When the raised panel folding-front writing surface opens and closes, sliding supports automatically extend and withdraw below the desk.

The lower section has five drawers with sliding dovetail joinery and four raised panels on each side. The bookcase has adjustable shelves, leaded glass doors, and crown molding coved on the table saw.

Materials Used: The full structure is made of 100% Black Walnut. The quarter-round molding for the leaded glass doors is handmade from Walnut. The bookcase portion uses ¾” thickness with 6/4” for writing desk. Back panels for the bookcase and writing desk, and the drawer bottoms are the only places where plywood appropriately spans those areas; ¼” Walnut plywood is used.

Comments

I used Black Walnut on every piece except the back of the bookcase and drawer bottoms. For those spans and drawer loads, I used Walnut veneer plywood. All the raised panels are cove cuts made by running the walnut at an angle to the table saw blade. All the moldings, like the crown molding atop the bookcase and the quarter round holding in the leaded glass were handmade by using the table saw, router, and a lot of sandpaper.

The lower cabinet main frame is made with 1-1/2” thick walnut and each drawer front is made using five different pieces of wood. Inside the drop front writing desk I bought, tooled, and inlayed leather as a writing surface. The brass arms on each side are connected to moving supports underneath the drop front. As the drop front is closed, the brass arms automatically retract the lower supports into the cabinet.

The leaded glass fit the door frames using “seeded glass” made with small air bubbles. The inside letter compartments and curved small drawers took almost as much time as making the upper and lower cabinet parts to the secretary.

I used two coats of “Tung oil” and let fully dry. Then added three coats of “Deft” for the finish.

A simple workshop with a 14" band saw, 12" planer, 10" table saw, 6" jointer, a drill press, and a 1Hp. router is all that was needed to build my Bookcase and Writing Secretary.

That is truly beautiful work. I am working on a desk, and I want to se a tooled and gilded leather top That has been laying around for years. I have a couple of questions first what kind of glue did you use to hold the leather to the substrate?

Second did you use a secondary wood as substrate? My guess is that the desk is Walnut routed out to fit the leather. I am thinking of first gluing the leather to a mdf substrate and framing that with a mahogany. For a flat top desk I think that will work. Any help you can offer would be appreciated.

TheStebb2, I used solvent based contact cement to bond raw leather to thin plywood. Once bonded and squared, I did the tooling for the border design. With the door made up of stile, rail, and raised panels, I cut the recess with a router and inlayed the leather using the same solvent contact cement. Then, I finished the leather with products from Tandy leather.

The leather makes a soft but firm surface to write on. Good luck with your project, too.

Bill

Log in or create an account to post a comment.

Sign up Log in