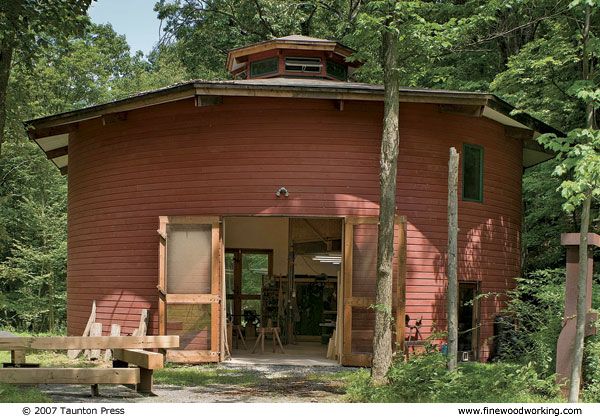

Rob Hare Workshop

Rob Hare’s workshop was featured in the Winter 2007 issue of Fine Woodworking, #195.

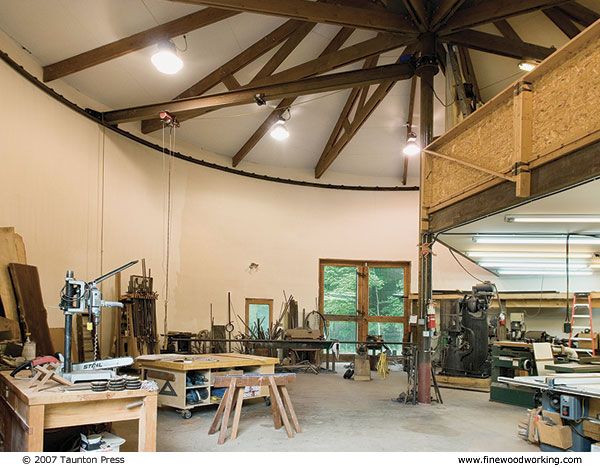

Because Hare works alone in both wood and metal, he needed a shop to accommodate both. The solution was a round shop that took Hare about eight months to construct. A crane, suspended from the ceiling and running on a track that travels the shop perimeter, can access the entire space and perform all the heavy lifting. Hare also figured out that a round space uses 15% less building materials than a square space of the same size.

The main floor (1,900 sq. ft.) affords enough room for bench space, a machine area, and a place to work metal. A balcony (about one-third of the floor space) holds the office and storage area.

Read more in Dream Shops.

For more by Rob Hare, read his article Flattening Tabletops and see some of his work in an audio slideshow.

Comments

nice Power hammer !!!!

That's one amazing shop Rob. I would love to see some more pictures of the shop. Maybe some shots of the equipment areas and the office area and anything unique to your shop.

Unfortunately Fine Woodworking doesn’t publish very large pictures of the shop submissions, or a click for larger image link. I can see the over head crane which is a very nice feature. “beers” mentioned a power hammer. If I put my nose to the computer screen, I think I can make one out.

By the way, the walls look smooth and not faceted. What is the wall made of and how was it installed? I'm probably past my question quota here, but maybe you could share some of the other construction details, or maybe you have them posted somewhere.

Thanks, Dean

Log in or create an account to post a comment.

Sign up Log in