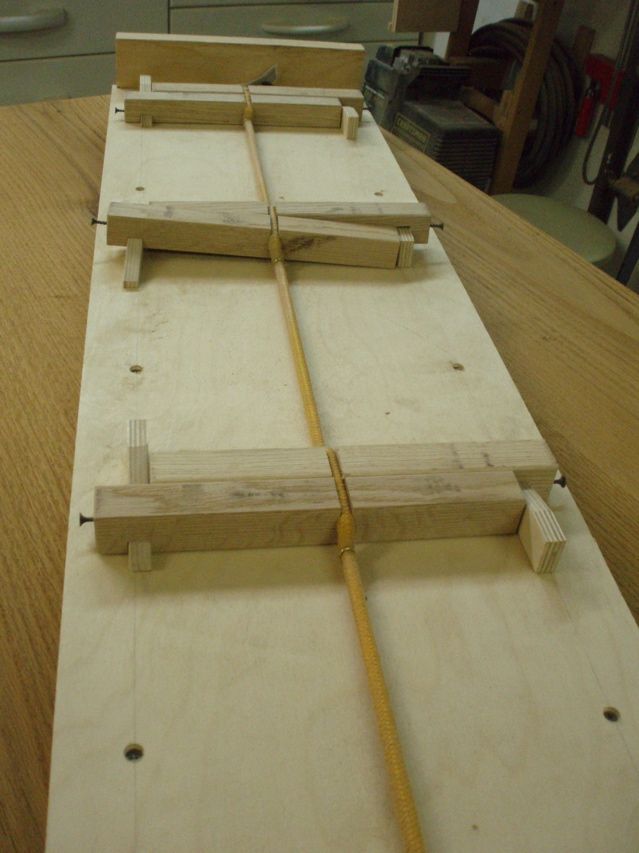

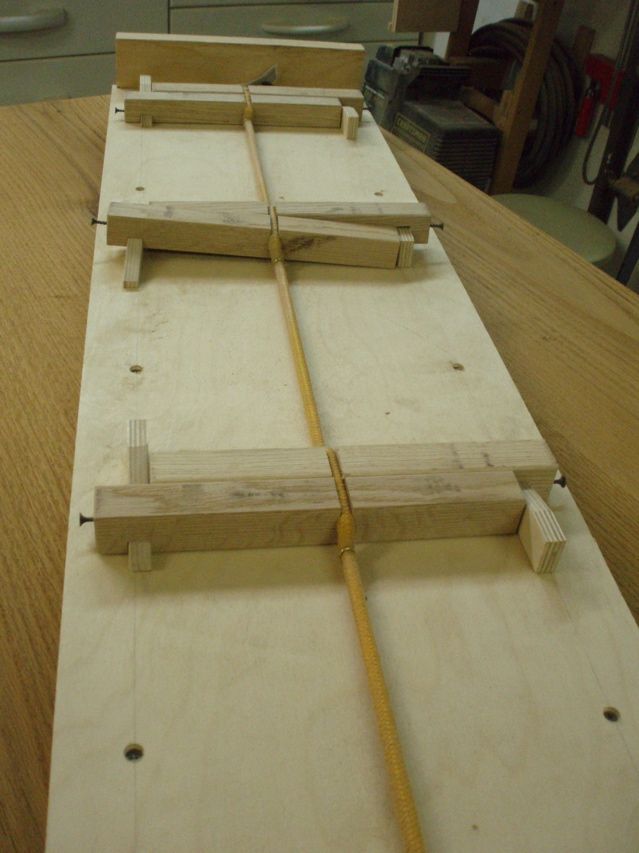

Planer sled for warped wide boards

I used the design of Keith Rust from FWW: January, 2005. Rather than the single support blocks in Mr. Rust’s design, I changed it to have double support blocks to provide more versatility, providing support on both sides of the board. I also put a block of wood at the front edge of the sled to prevent the board being planed from slipping forward off of the blocks. I used it recently to make 2 tables and it worked great. I was able to get 12.5 inch wide boards from warped and twisted boards.

Comments

I don't get it. I might if it was just a sled for warped boards, but a "planer" sled?

woodworkerscott & all

The excellent original article (and video) by Keith Rust from FWW: January, 2005 shows how, by mounting a warped board on this sled, you could pass it thro a thicknesser and have the overhead cutters plane a flat surface on the top surface of the board. By then removing the sled, turning the board over, and using the flattened surface to register the board as you pass it back through the thicknesser you get both a planer (FLAT SURFACE) and thicknesser (PARALLEL SURFACE) from one (quite pricey) tool instead of two. 12" planers are not cheap (enough) - yet.

The original is a great/practical jig. This variation is a real upgrade in so far as it allows you even more flexibility to secure the board from rocking. The careful placement of those cup hooks quite close to the crossbeams, the letting of the bungey cord into the beams to align them, and resting the beam ends against the opposing wedge are all simple elegant upgrades to better secure the wobbly board.

I now use the 15% sliding wedge design I saw on the original jig in almost all levelling tasks - I am cheap too!!!

The law of diminishing returns when using freaking out bannana bread wood that is too warped - it tends to keep on warping and the resulting boards get smaller and smaller - is now the real issue.

This jig is (imho) well worthy as a contender for a prize in this contest.

Cheers

Jock

I think he called it a "planer sled" because it allows you to pass a warped board through a "thickness planer" (thicknesser to those outside of N. America) and get a pretty good jointed surface. So it is "just a sled for warped boards."

Or at least that's my take on it, I'm a neophyte though, so please feel free to correct me.

I built one myself folowing the original article and it's given me some pretty fine results. I'm not that happy with my current supports though, nothing wrong with the original design, rather my execution. Mine are too wide for the size of my wedges and so they are a bit unstable, and my wedge material choice was... poor, go with a decent hardwood, not just some scrap.

So when I redo them, I'll probably give these upgrades a try.

For any other beginner out there, take care to assemble your sled on the flattest, truest surface you can find, as I keep hearing over and over again, spending more time here will pay off in the long run.

I made the "planer sled" and it works good. I fixed small blocks on each side of the cross bar to prevent any movement when planing or moving the jig around with a board. I used the jig with 8/4 and 6/4, 9" to 10" wide, hard maple for a dining table and six chairs. The jig save me a lot of time to get the fisrt flat surfaces of the boards. The down side is the heavy weight when returning to the infeed side. You must be carefull when it comes out the thickness planer if the board is shorter then the sled, because of the heavy weight it is a bit unstable and the last end may hit the knives of the planer, a roller outfeed stand is a must. I have a 15" thickness planer from General.

Very good jig, it's worthwhile

AGB/Galopin

Jock, if you were truly cheap, you'd ask yourself why the rubber tubing runs the length of the jig.

If you snip small pieces, you could get DOZENS of jigs or replacements out of one piece of surgical tubing.

THAT'S cheap. Others are merely contenders to the title. :)

me neither but i wish i had the plans for making it so i could try it.Sounds like a great money saver

deAngelo: The FW video addresses the issue of weight transfer - it is a real consideration - but as you watch him process a board you will see he has a practical, if hard work, solution for weighty wood transfers.

Jammersix: The 'rope' is a bungy cord not surgical tubing which I would think would be too weak for this task over the long term.

Dusty9: Modifying this article/video into plans should be very straightforward.

https://www.finewoodworking.com/.../SkillsAndTechniquesArticle.aspx?id=5245

the address for seeinig this jig in action doesn't come up on my comp. But as i look at it over the months,i hope to figure it out by looking at the pictures,and discerning the whole idea.Thanks.

Dusty9

Sorry the link didn't work - try a search under . . . A Planer Sled for Milling Lumber - it came right up at the top of the list for me

Jock

Here's the correct URL for that video:

https://www.finewoodworking.com/SkillsAndTechniques/SkillsAndTechniquesArticle.aspx?id=5245

Great contribution, BTW.

PapaBear

Just cleaned up 160 board feet of white oak with this sled. Now moving on to my router table with a spiral bit clean my edges.. fantastic jig!

I had a crack at making this sled for my home small thicknesser, I made the 15 degree inserts (that adjust the height)to thin and therfore when the board goes through the thicknesser the board moves and the jig doesn't work. I will have to make the supports out of thicker material...just a comment for those who want to make this jig.

I had a crack at making this sled for my home small thicknesser, I made the 15 degree inserts (that adjust the height)to thin and therfore when the board goes through the thicknesser the board moves and the jig doesn't work. I will have to make the supports out of thicker material...just a comment for those who want to make this jig.

Log in or create an account to post a comment.

Sign up Log in