Interior Yacht Cabinetry

I am currently attending the Northwest School of Wooden Boatbuilding in Port Townsend, Washington and in my final quarter. Looking to jobs and opportunities that lie ahead I have been coming up with a few different plans. I now know that I will be attending Savannah College of Art and Design for furniture design so that i can one day open a yacht specific custom interior cabinetry shop.

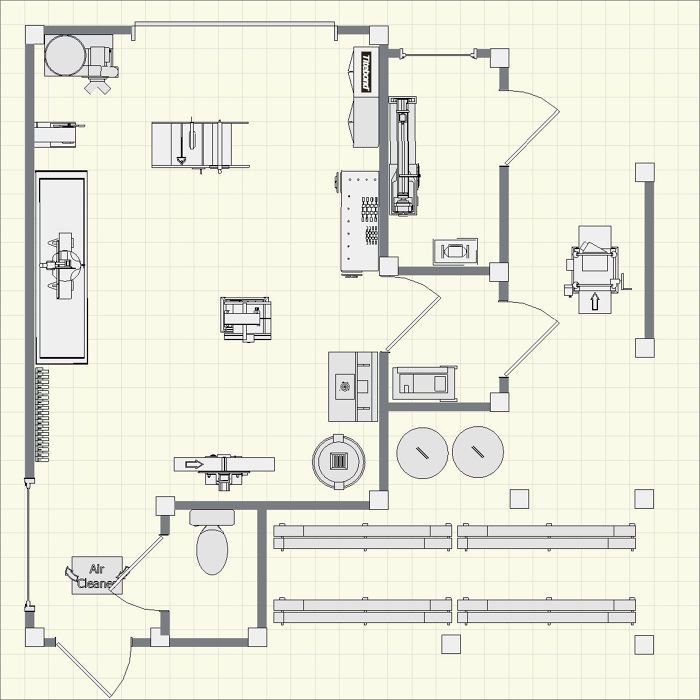

The shop I have designed incorporates a lot of the needs for boat building and what I have learned from my time at the school and jobs past. First the Post that seem to be floating randomly by the lumber racks and the wall next to the planer are open air sections with roffing overhead. The lumber racks are long to accomodate planks if I decide to build a boat, or replace planking. There is no reall need for walls around a well built lumber rack and I like being able to fully walk around the wood pile. The planer is open to the air so that i can thickness plane any lenght of material I need, and it makes cleanup of shaving easier by not throwing them around the shop.

The shop has been devided into sections for ease of cleaning and organization. I have put the compressor in a seperate walkthrough room to reduce the noise it creates, but kept it easily accesible in case something happens to any of the hosing. I plan on routing coiled hosing through the ceiling and dropping it by the lathe, work bench, and the miter saw.

I have seperated the lathe, again for ease of cleanup. It keeps the shavings in a confined area, and the seperate room helps me keep the turning tools in one spot. i have also included my grinder because i mostly use it for sharpening lather tools.

The table saw is placed so that you can load longer pieces of wood throught the garage door and not have to worry about running into the wall.The bandsaw is also arranged this way, but I will most likely be moving it around so it will be on a well built rolling base to accomodate for size.

The jointer may seem like it doesn’t have a lot of room, but I would realistically get an 8 or ten inch wide jointer and that would mean haveing a relatively short table on either side. Plus a jointer is only made to joint a piece about twice it’s length at the maximum. This will also be on a rolling base for easier movement as necessary.

The Chop saw is on a long workbench fixed to the wall to stay level. with four feet of table on either side it should easliy work with the lengths of cutI would be working with and I could also use the table as an extra work bench.

The tool and glue locker are near the door, because it will be cooler there and better for if I am storing epoxies to help keep them from the heat.

Finally the entry way with access to the bathroom. The bathrrom is just a bathroom. The entryway will have a hanging locker so that if I am working with lead I can hang my clothes at the shop to reuse without taking lead particles away from the shop to family members. It also has an air cleaner to further reduce the transiton of harmful dust and contaminates that are common in the workplace. Oh and I will have tons of clamps all over the walls, you never can have enough clamps, I’m always needing more for different projects.

Log in or create an account to post a comment.

Sign up Log in