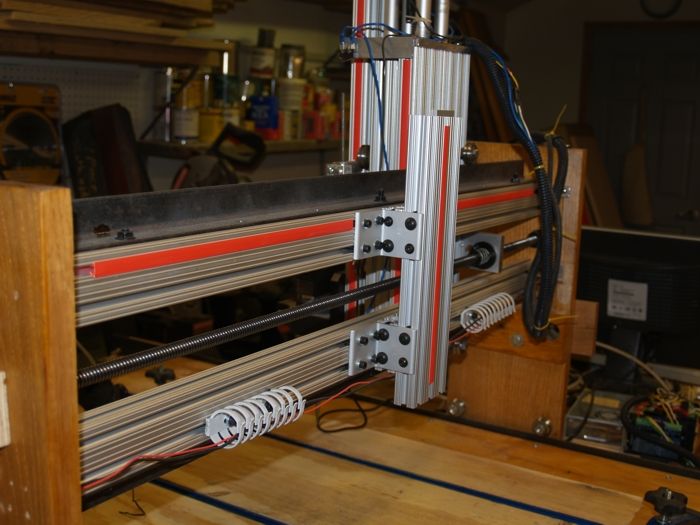

updated CNC machine

Using extruded aluminum for the gantry cut down on the weight of the xAxis as well as made making the entire machine much more precise.

The update to my original CNC router design. I traded out some of the weaker wood for extruded aluminum and made some changes to the gear ratio on the x-axis as well as moving the pillow bearings to the outside of the shafts on the x-axis creating a much more stable design. The x-axis is much more solid giving at least a .01 inches of precision if not better. The CNC router is 3ft x 4ft and the z-axis travel is over 7″ allowing for some nice size projects to be made. Once completed this was still at least 1/2 the cost of the small carveright or sears carving unit. Compared to the larger machines … it’s a huge savings.

Comments

Can you recommend sources for G-Code archives of carvings, etc?

Log in or create an account to post a comment.

Sign up Log in