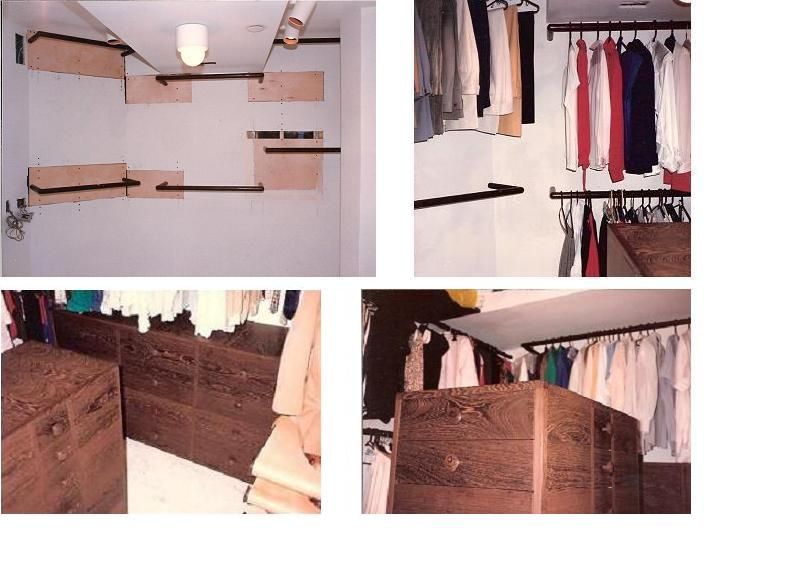

Wenge Closets

This project was done in 1985. All of the woodwork shown in these photos was constructed using solid wenge only, no veneer. In the case of where veneer was needed I had resaw the solid planks of wenge to produce my own veneer. The leather shoe pullouts consisted of 2″ hollow pvc pipe plus non-visible ball bearing drawer slides were used to construct the sliding mechanism then veneered around the visible areas of the pvc pipes. The wenge disc was hand made from solid wenge to be used as the pull. The leather pullouts were cut from 1/4″ sole hide, having a curled lip as a handle or pull. These pullouts were intentionally designed to appear like a stack of ancient scrolls. All the wenge was hand rubbed with paste wax and then hand buffed to a satin finish, including the interiors of every solid wenge drawer box that contained a t&g lock joint method of assembly. The wenge closet rods had 3/4″ by 3/4″ square steel bar stock used for re-enforcement. The steel had been glued within the wenge which was bolted from the rear through a 1/4″ thick, 6″ by 6″ square steel plate, then hung on the wall with a 1/2″ baltic birch plywood wall plate. The heavy duty rods were designed and engineered to hold 100’s of lbs per rod. The center island cabinet had one small top drawer with a key lock, when opened a secret lever inside allowed entry into all the other drawers. The client had special ordered 8 cylindrical marble legs from Italy that were 250 pounds each. They needed to be rolled from the shipping dock into the elavator, rolled down the hall, 3 or 4 people had to raise each one into an upright position at the final resting place in a very large open living/dining room space. Special thanks to master woodworker Mark Krenz, who contributed his precision skills and expert knowledge to the entire project. And on behalf of the finest designer I know, Kiril, the job turned out to be a true classical work of art.

Log in or create an account to post a comment.

Sign up Log in