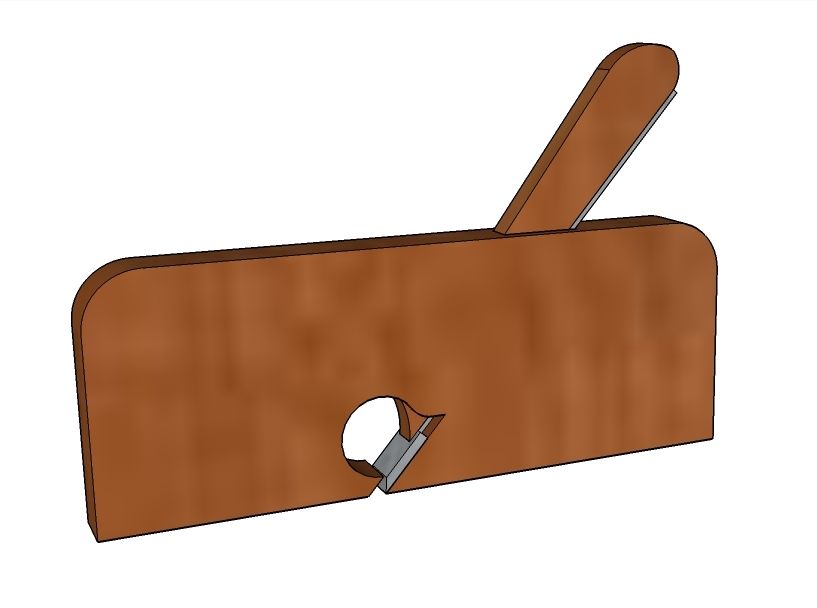

Shoulder plane

The only wood I had available for this was a chunk of 8/4 white oak. Most annoyingly it was almost perfectly rift sawn, instead of quarter. Not to be deterred, I marked out the plane dimension on the end grain, tilted to make it quarter sawn, and went about removing the waste to reveal my new plane. Once this was cut out and cleaned up, I had a 1x5x12 block, ready to be worked. Before doing so, however, I took a lesser piece of white oak and made a test plane. This proved most helpful and provided plenty of insight as to technique and tools needed to get the job done. A jig, Iwasaki rasp, needle rasp and fair amount of sweat later, I have a new tool.

It still needs a bit of tweaking but will soon be cleaning up my parts.

You can see in the original Sketchup design that the blade was placed further back. I decided that I’d like a little room for my hand so I moved the blade and wedge forward a bit.

The blade is set at a fairly steep 60 degrees. I can turn the blade over and get an almost 90 degree cutting angle for difficult grain.

Log in or create an account to post a comment.

Sign up Log in