Modern coffee table – Origami

Origami coffee table is now in production and we are happy to share couple of images with you of the fabrication process. We always feel it’s important to give you a bit of “behind the scenes” insight. This particular coffee table is being locally made for a client near Mavis & Eglinton st. in Mississauga, Ontario.

1. Material choiceBased on the client’s requirement to keep the price as low as possible, we decided to choose more affordable material. Her preference was light wood material and after a couple of samples reviewed, she chose cherry wood with a clear lacquer finish.

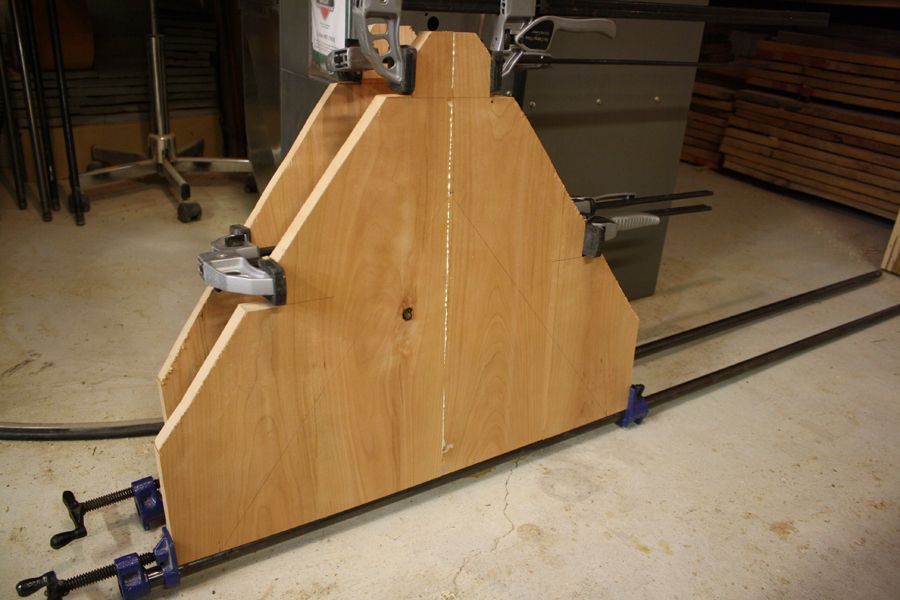

2. The gluing processOnce the wood was planed down to a specific thickness and glued-up, it was ready for the table saw.

3. The cutting processIt is the specific angle cutting that gives the Origami coffee table its unique look. If you are an experienced wood woodworker, feel free to grab the shop drawings with all the measurements and angles.

4. The assemblyAssembly requires a professional touch and woodworking experience to make sure everything works just right. Slight inaccuracies may create many problems with the glass hardware and the table can also lose its beauty & intricate simplicity.

5. Jig drillingOnce the wood is cut and wood base is assembled, a drilling jig will help us to make an accurate hole for glass hardware. After that, everything is ready for the glass top that goes on top of it.You can also subscribe to our newsletter to be autocratically notified of new blog posts.

Log in or create an account to post a comment.

Sign up Log in