Workbench from ‘Getting Started in Woodwork’ UK

Completed Bench (well almost)

I have always wanted a sturdy workbench but have got by for the last 30 years using a B&D workmate, so as I have recentlly retired decided to build one. The Fine woodworking video’s and PDF plans were great and made it (fairly) easy for a novice woodworker to construct.

The first issue for me was that all the measurements were imperial but as I live in UK I needed to convert to metric.

So I purchased the following (thought this may be useful for anyone making in the UK):

4 x 2.4m long 100mm x 50mm planed pine

2 x 2.4m long 100mm x 100mm planed pine

1 x 1.2m x 2.4m sheet of 18mm MDF

I used Ash for the vice jaws

3 pieces of 5 ply glued for the vice spacer block

1 bottle of Evostick wood adhesive

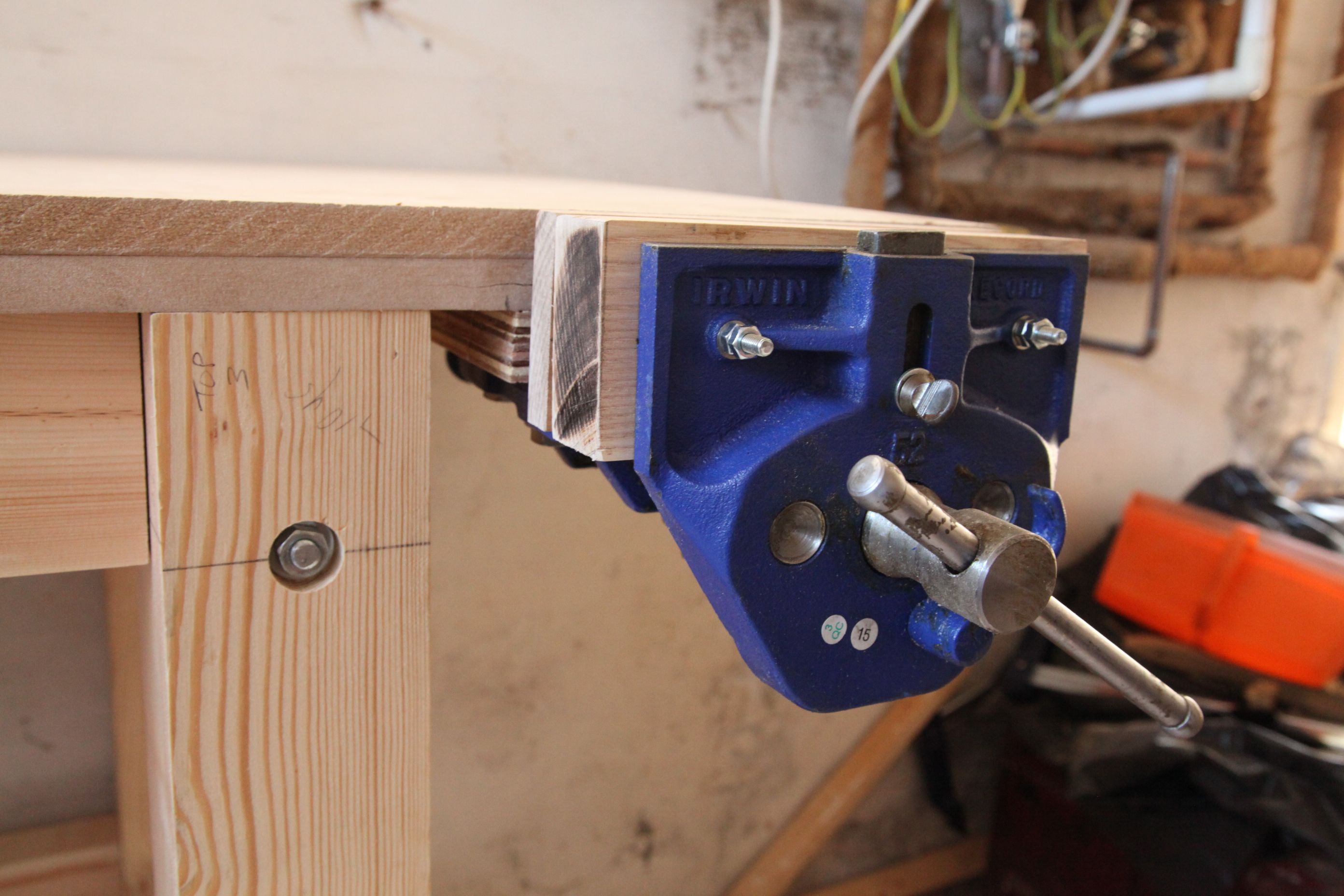

1 7-in. Irwin Record 52ED quick release vice

4 x 2m lengths of M10 threaded rod

16 x M10 penny washers

16 x M10 hex nuts

4 x M6 60mm bolts, washers and nuts to fit vice jaws (cut to size for front jaws with a hacksaw.

1 Box of 3.5 x 32mm drywall screws for laminating benchtop

4 x M10 x 70mm long coachbolts for attaching vise

16 homemade hardwood buttons for attaching tabletop as I could not find a UK supplier of S-clip table top fasteners and postage from USA was too expensive.

16 x 10mm dowels, roughly 40cm long

A few points that might help:

Definately use the jig thats mentioned in the video – it makes cutting straight so much easier. I used two pieces of plywood (7 ply and 3 ply).

The router bit I used was 10mm and cut the reccesses 10 mm from the edge. (My routing was fairly poor as it kept drifting but luckily you dont see the routed slots.) 10 mm does mean a very tight fit for the threaded rod and i had to gently hammer them into the slots.

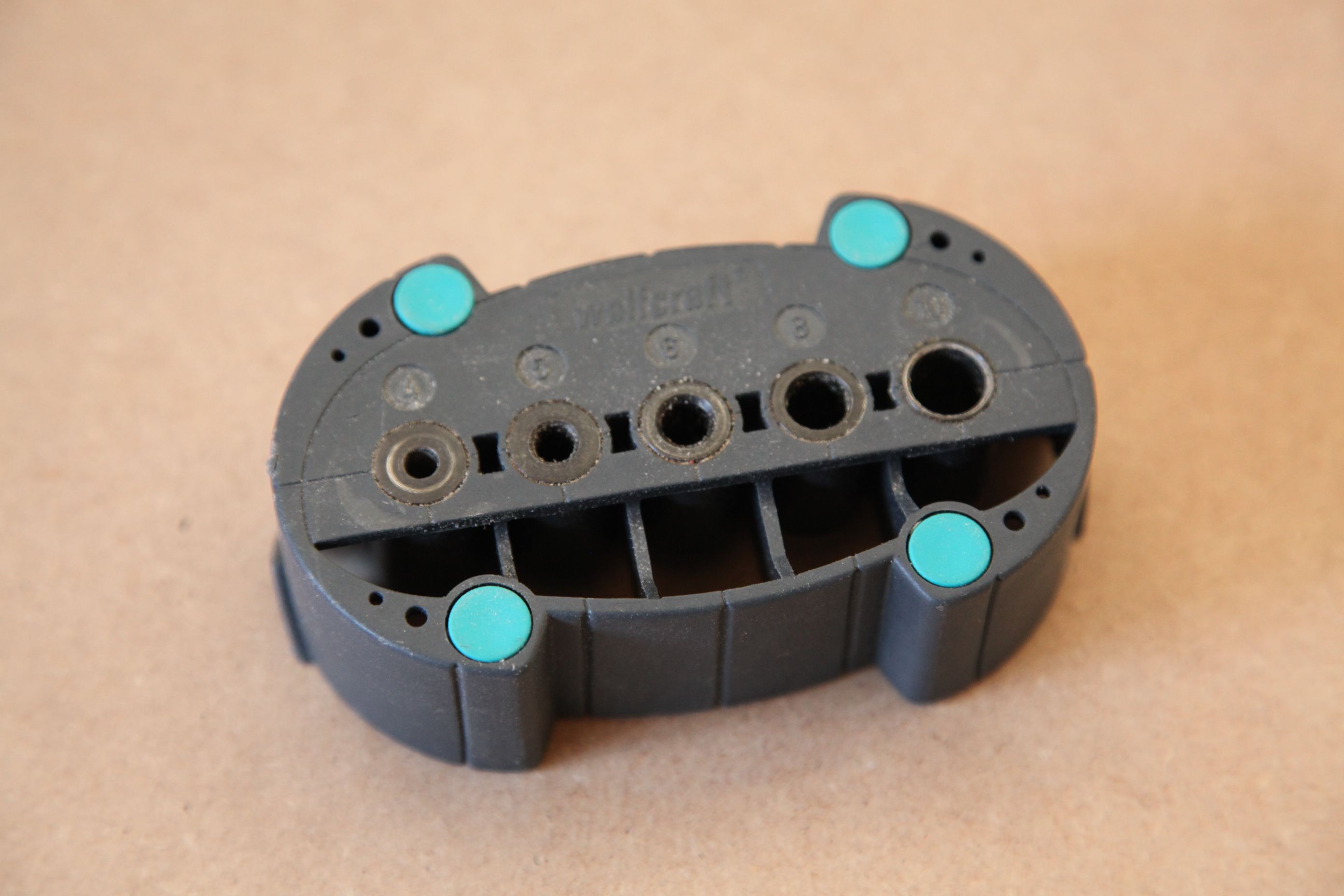

The Wolcraft mobile drilling aid wasnt perfect but it did help keep the the 10mm holes through the legs perpendicular. (I dont have a drill press – yet…)

I could not get hold of the s clips so made some buttons from a piece of Ash. I used a metre of 18mm x 50mm and routed an 8mm rebatealong the length, then drilled and countersunk 4mm holes every 4cm and then cut them into 4 cm lengths. Quite easy to do and they fit well in groove and hold bench top firmly. I used MDF Tite 3.9 x 45mm fibre board screws.

For the vice the recmmended Groz doesnt seem to be in production any more so after reading a number of reviews went for the Irwin Record 52ED quick release vice – very sturdy and quick release mechanism works well. I fitted with Coach bolts (pre drilled holes) and they do hold very securely.

Hope this helps anyone else in the UK building the bench.

Comments

I would love to know how the MDF is working out for the benchtop. Is it staying flat all dimensions? What will you do when you ding it up? Is it easy to split the layers to put on a new layer? Other ideas? Thanks.

Log in or create an account to post a comment.

Sign up Log in