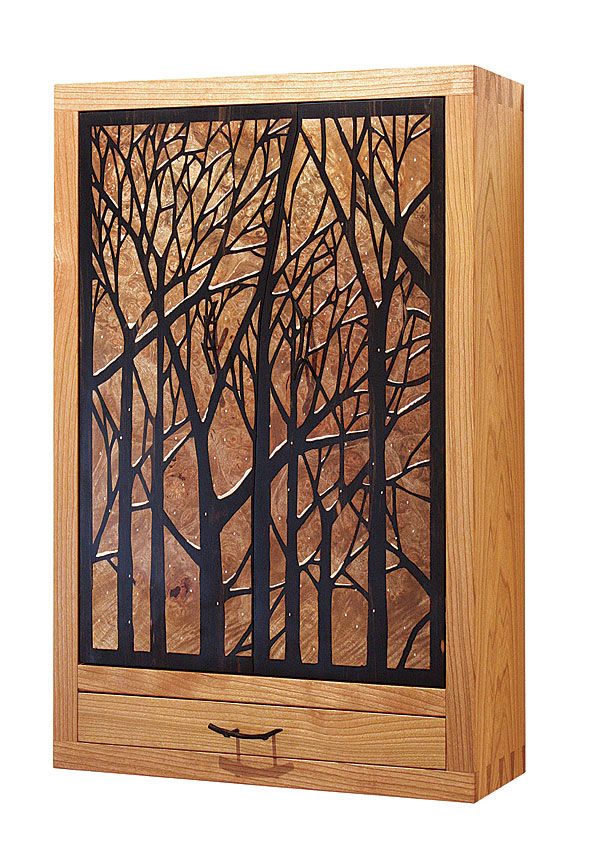

Marquetry Patter Jewelry Cabinet

Woodworker: Al Ladd

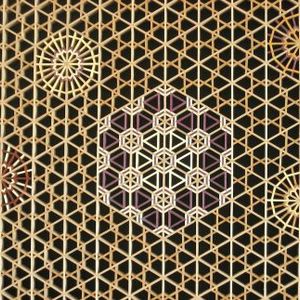

Ladd designed and made the marquetry pattern on the doors of his jewelry cabinet (5-1⁄2 in. deep by 15 in. wide by 24 in. tall) with the help of a CAD program and his shop-built CNC router. Rather than cutting hundreds of small pieces of veneer and fitting them together to make the image, as you would with traditional marquetry, Ladd used the CNC rig to cut positive and negative shapes in full sheets of shopsawn veneer and then sandwiched them together.

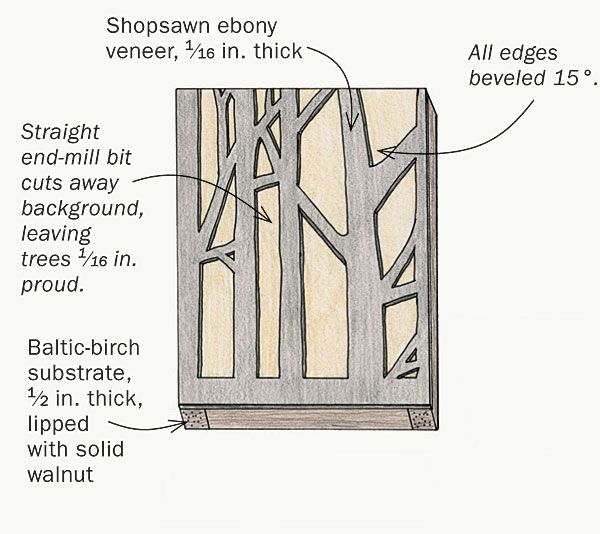

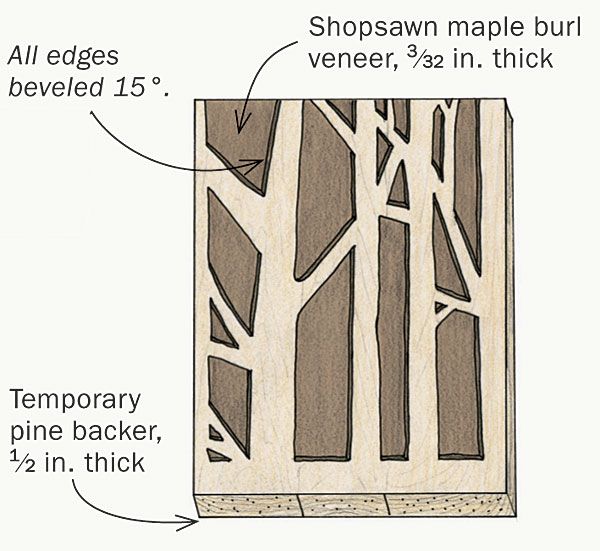

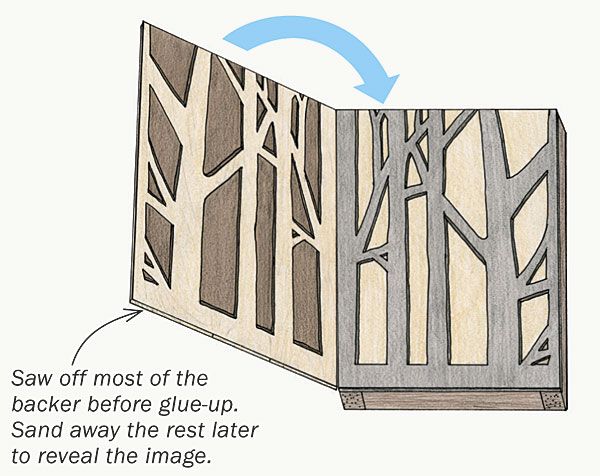

He began by gluing a sheet of ebony veneer to the door-panel substrate. He routed away all the background, using a V-bit to bevel the edges of the ebony. To make the mirror-image infill pattern, Ladd glued an extra-thick sheet of maple burl veneer to a temporary backer of solid pine, glued that on, and then sanded away the pine to reveal the picture. To add the holly snow, he repeated the process. Ladd’s neighbor, blacksmith Justin Morrell, made the twig pulls.

CNC Routing Creates a New Kind of Marquetry

This is how Ladd combined the ebony tree pattern with the maple-burl background. After sandwiching them together as shown, he cut away pockets for the snow on the branches, and married that with the snow pattern, which he routed from a sheet of holly veneer on another pine backer.

Comments

Beautiful! Wow.

Log in or create an account to post a comment.

Sign up Log in