DIY Dust Cyclone Separator

The completed cyclone

I had been looking in many issues of woodworking magazines to find a dust cyclone cyclone, but found that the shipping costs to Europe were prohibitive. Finally, I found some smaller ones on eBay, Okay for small orbital sanders and routers, but undersized for a central separator job ( I’m using a Camvac 2.5 inch dust extractor, 110 CFM).

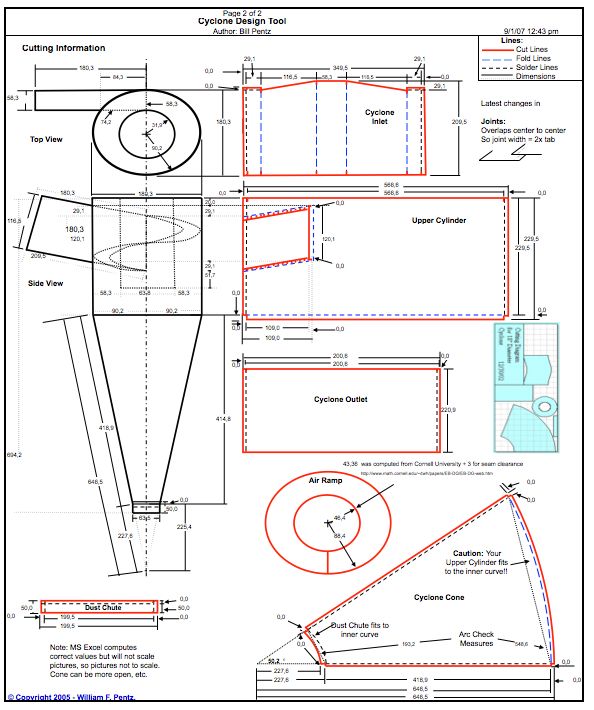

I started researching, and found two absolutely great sites, which should be mandatory browsing for all woodworkers. (1) Flowering Elbow, which planted the idea of building my own cyclone separator, and (2) bill penz’s website, which represents the Bible of Dust Collection and Cyclone Design. Awesome, impressive, superlative etc etc. His website even offers a cyclone sizing/calculating Excel spreadsheet!

I’m not a metal man, I cannot weld, That left me with a nice little puzzle how to build such a cyclone. On one of my outings, I got stuck in road works, and there was my Solution.

Believe it or not, but I went to a regular store to purchase a traffic cone, which sells for less than 10 US$ each.

The cyclone separator has three main parts: (1) an upper cylinder, (2) a middle (traffic) cone, and (3) a dust bin. For the upper part, I used a 180 mm ( 7 1/2 inch) diameter stovepipe, into which I cut an opening according to the Bill Pentz design sheet.

The interesting thing about this design was the air ramp in the upper cylinder. This forces the air down into the cone ( and ultimately in the dust chute), whereas the “clean” air travels upwards to the central vertical tube. A skewed inlet helps orient the dusty air downwards.Works very well for collecting chips. I’m not yet sure how much (fine) dust is captured, that is the next step.

Log in or create an account to post a comment.

Sign up Log in