It’s not pretty, but it works. My 2nd prototype workbench.

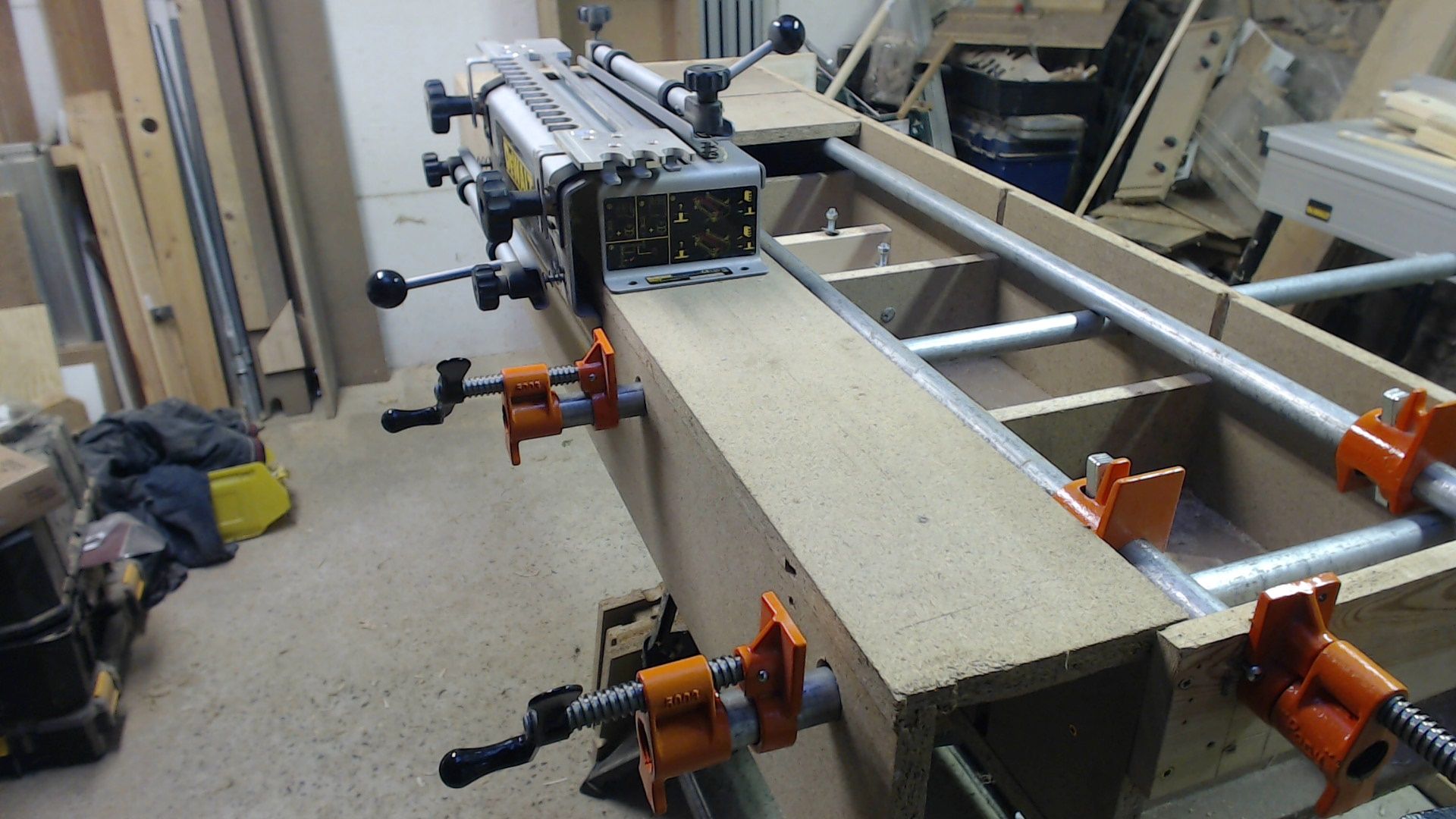

Workbench set up with removable planing beam, clamped to the nearest face, table mounted jigsaw, drill press and sharpening station.

I wasn’t sure if this counted as furniture, shop pics, or jig pics, so I just used the first option on the page.

I was impressed with two designs of workbench from FWW, the new fangled workbench, and the ‘two boxes and two saw horses’ workbench. Since I only have a small shop, I made a mix of the both.

This bench (and it’s predecessor, that you can sometimes see leant up against the wall in the background) was designed to sit on my workmate. Mainly so that I can stand it up out of the way when I need to work on the kids bicycles or spring clean the workshop or some such.

As with the first workbench, this is a prototype, made with reclaimed materials, in this case chipboard that had been used for shelving, but which was still nice and flat (if rather grubby looking). The joinery is all dados, glued and screwed, nothing fancy.

The profile is a sort of lying down S shape, clamped in the workmate on the bottom of the larger section. Pipe clamps run up the main well, per the new fangled workbench design. I also have additional pipe clamps that can be used crossways as well (they are not specific to this bench, so extend further than the width of the bench (I plan to build a couple of outriggers, to give me more width options in the future)).

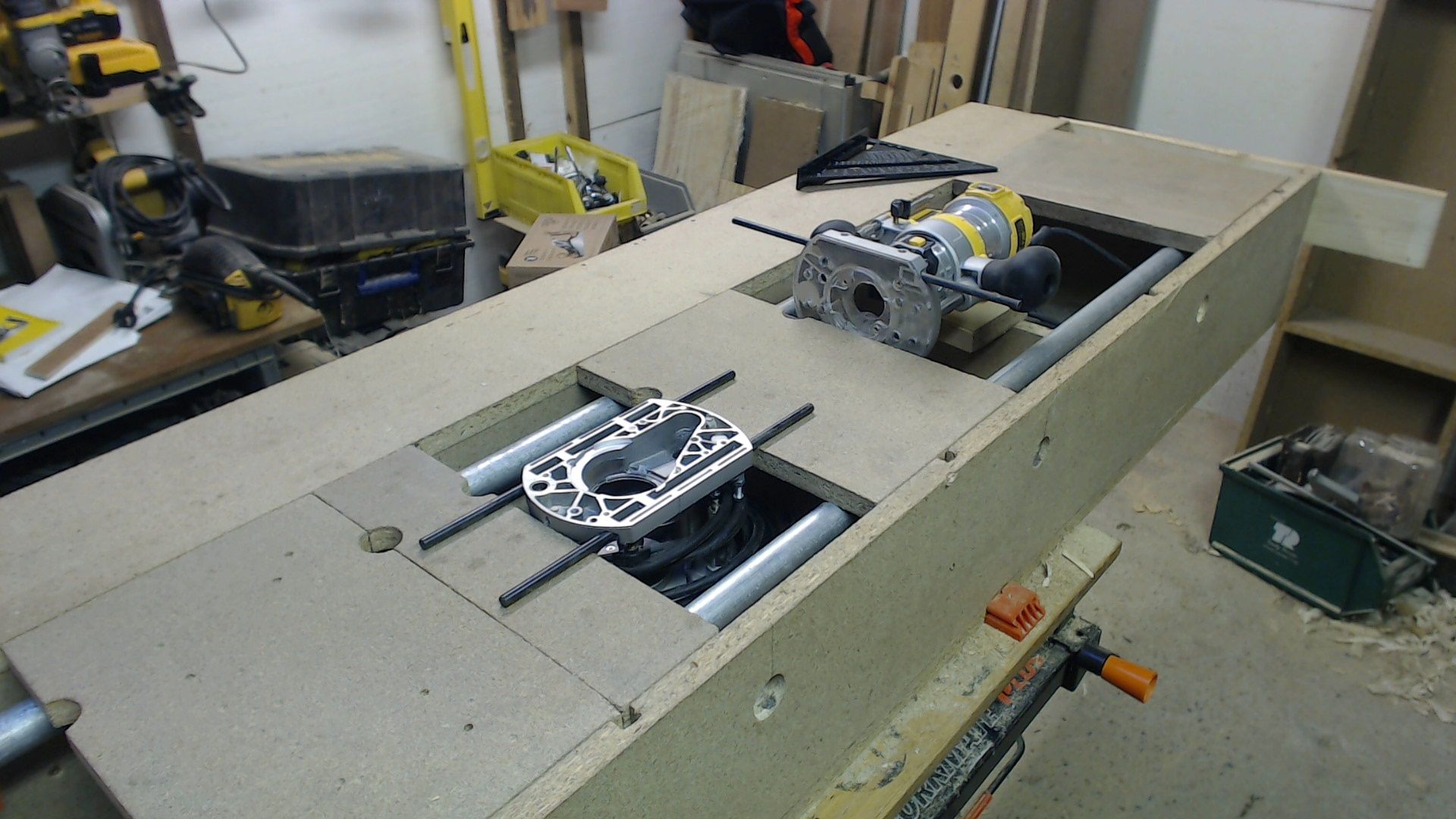

I have cut a hole in the bottom of one section, so that I can mount power tools underneath a section of the top. Jigsaw is already done, router table to follow.

I have also set a mounting block for my drill press, so that the base sits under the benchtop, this means that once the benchtop sections are replaced, that I can set fences anywhere I reasonably want. The mountings are positioned such that the press tube is aligned with the finger holes (which was the reason I drilled them in either end, rather than the middle of the benchtop sections). I have also mounted a sharpening area on one section for chisels and plane blades. That is an accessory power planer shoe, with REM’s glued in, that hold one of those diamond sharpening sheets in place and flat. Again, not pretty, but it gets my chisels sharp enough to take teh hairs off the back of my hand. (The original diamond set had four grit grades on four sides, but the quality of the box wasn’t very good, so I disassembled it, and now use just the diamond sheets.)

I made a copleletly removable planing beam that sits on top of the smaller section, with pipes beam and top that can be removed and stood up out of the way. The sharp eyed among you may notice that the pipes appear to have two sections, with a joining piece. This is so that if I lower the workmate to it’s lower position, I can remove these sections, and still use the planing beam.

Looking forwards, I am going to see about a horizontal and a vertical router mount, and see if I can mount my belt sander as well, so I have a stationary belt sander.

Log in or create an account to post a comment.

Sign up Log in