Sawhorse Workbench

Gents,

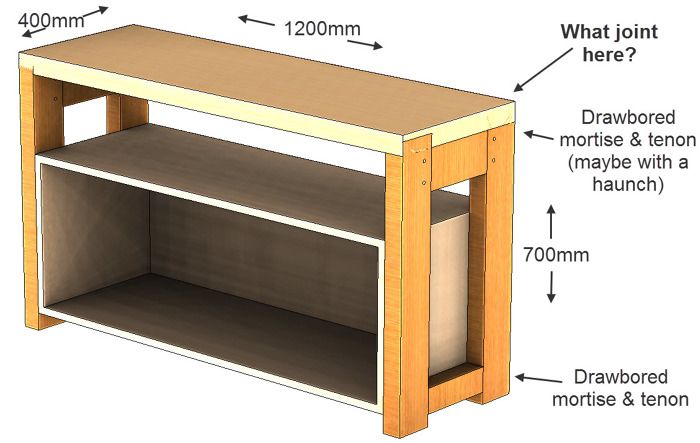

This is an idea I have for a sawhorse that doubles as a light workbench for indoor use. In the future I plan to make add another sawhorse and a couple of torsion boxes so that I have tha same setup as Joshua Finn (article “Forget what you know about workbenches).

As an intermediate newbie to woodworking, this projcet is both a way to practise and try out a couple of techniques, and a much needed workbench.

I don’t have a workshop, so it’ll have to be pretty enough that it can be inside. Basically the plan is to make some sturdy legs of white oak, a top og white ash and a plywood box, possibly with drawers below. The Plywood box serves both to add stiffness to the design, as well as some much needed weight. I’m making it easy to replace shold I want to replace it with something a bit more classy in the future.

What I need a little help with is how I should fasten the Ash top to the oak legs. I was thinking to keep it simple and use the reg-jig to fasten it, but I feel like I’m missing out on an opportunity to learn something here.

Comments

Hello,

Very nice idea. Battens under the top just inside the legs, three screws into the top with the holes for the outer screws being elongated to allow for movement, a couple screws through the sides of the battens into the legs. The batten then controls warpage of the top and fastens it to the base.

Cheers,

Thank you very much!

Yes, that makes a lot of sense. I've recently developed an allergy to screws with prevents me from thinking clearly at times..

Cheers,

Nice idea, two suggestions:

Since you are relying on the storage plywood box to prevent side to side racking, use a full thickness board for the back and rabet it into the case;

And use either hinges to connect the leg assemblies to the top if you want it folding, in which case four screws from the inside of the box into the legs on each side, or a large dovetail from each leg too to the top plank. You can then make the top from top thick planks with a gap between them to slow more clamping options.

Whatever you do, good luck and enjoy.

Thanks Slowman, and good input!

The design does indeed like it can be changed to allow for it to be folded. I'm initially a bit worried that hinges will make the thing a bit wobbly (after a few years of use at least), and I have to think about this benefits my needs.

For uniformity (is that the correct word?) I think I'll do a double laminate of ply for the back of the Ply-box. Should be stiff enough and gives me a rabbet all the way around too. A quick flush trim with a router and then its done.

Thank you very much for your input, I'm starting to feel confident that this could turn out good! In any case I'll learn a lot and have hours of enjoyment.

Nice Project.Thanks

I appreciate with your work

Log in or create an account to post a comment.

Sign up Log in