Sliding Bench Jack Holds Boards on Edge at Any Height

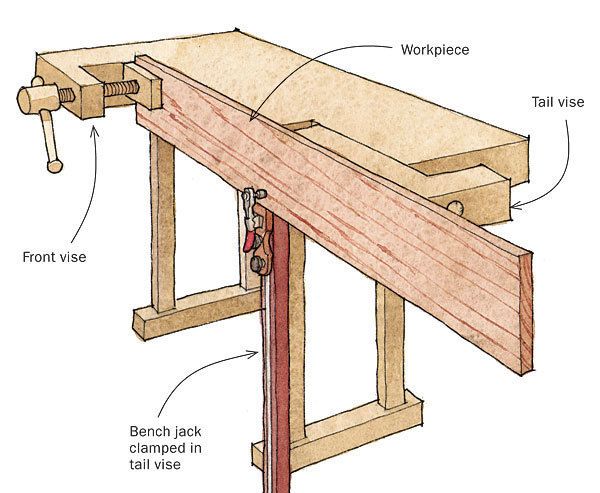

To plane a long board on edge, woodworkers often clamp one end in a front vise and support the other end on a device known as a bench jack.

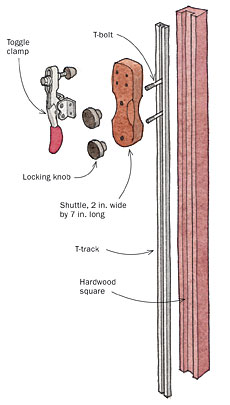

A traditional bench jack is clamped into the tail vise (either L-shaped or full width) and uses a dowel to support the workpiece. The jack often has holes from top to bottom that allow the dowel to be adjusted for different board widths and working heights. This adjustment method is relatively crude and doesn’t restrict the board from wobbling from side to side as you plane it. So I came up with this design, which features a sliding shuttle equipped with a toggle clamp (DeStaCo No. 225-U; www.grainger.com) to hold the board against the bench.

In use, the bench jack rests on the floor and is clamped into the tail vise (for a bench without a tail vise, you might attach the jack permanently). I adjust the shuttle by loosening the knobs and simply sliding it up or down its T-track. Once the height is locked in and the material is resting on the shuttle, I flip the toggle clamp. The toggle clamp can be adjusted to accept materials as thin as the shuttle (3/4 in. in this case) or up to almost an inch thicker. If the workpiece is thinner than the shuttle, I add a spacer between the clamp head and the workpiece.

With the workpiece supported and clamped into the jack, it is ready for planing, shaping, or sanding. The material will be held firmly at the desired height with much less side-to-side movement.

Drawings by Jim Richey

Drawings by Jim Richey

Fine Woodworking Recommended Products

MicroJig Matchfit dovetail clamps

Incra Miter 1000HD

Hedgehog featherboards

Log in or create an account to post a comment.

Sign up Log in