Easier Tablesawn Tenons

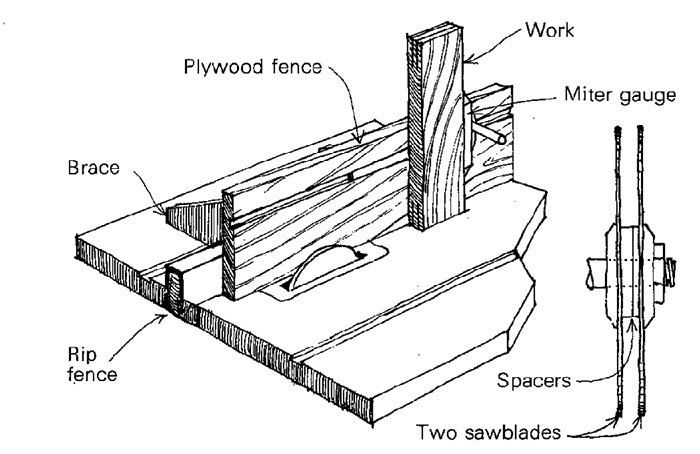

This method for cutting tenons on the table saw uses two blades with spacers between. The beauty of this system is that the tenon thickness is “locked in” and does not depend on variables such as stock thickness or pressure against the fence.

I keep a pair of special hollow-ground blades for tenon work. They are jointed as a pair and filed for ripping. Since the hub and tooth thickness are the same, cutting a 5/16-in. tenon, for example, simply requires mounting the two blades with a 1/4-in. and a 1/16-in. spacer between. My set of custom-machined spacers are 2-1/2-in. discs drilled to slip over the saw arbor. Spacer thicknesses range from 1/4 in. to 0.005 in. To pass the work through the blades, I use a standard miter gauge tracked in a plywood fence as shown above. This approach eliminates vertical rocking and thus is safer and more accurate than other methods.

Mac Campbell, Harvey Station, N.B., Canada

Fine Woodworking Magazine, August 1980 No. 23

Fine Woodworking Recommended Products

Freud Super Dado Saw Blade Set 8" x 5/8" Bore

Woodriver Circle Cutting Jig

3M Blue Tape

Log in or create an account to post a comment.

Sign up Log in